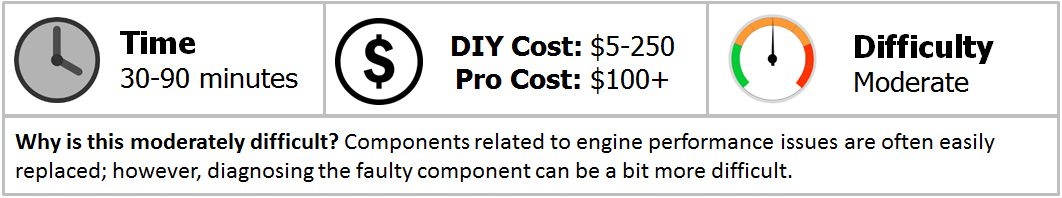

Toyota Tundra: Performance Diagnostic Guide

Toyota has proclaimed that the Tundra is built tougher and stronger than any of its American counterparts. Known for its bulk and brawn, there is no question why the Tundra is a 2-time truck of the year award winner. That said, even the Goliath of trucks can have its share of issues that will hinder its performance.

This article applies to the Toyota Tundra (2000-Present).

The OBD-II (on-board diagnostics) system fitted on all Toyota vehicles has the ability to alert the driver when an engine performance related issue arises. With the use of multiple sensors monitoring various engine functions, the computer can often determine exactly where the problem lies and, in-turn, stores a fault code that can be retrieved at any time with a code reader. Even though vehicles are becoming increasingly computerized, they can still suffer from various issues that will negatively affect performance and drive-ability without setting off the malfunction indicator lamp. In the case of the Toyota Tundra, there are several common components that can limit engine performance and suck the joy out of driving your truck. This article will outline a number of different components that have been known the cause a lack of performance on 2000 to current Toyota Tundra trucks.

Materials Needed

- OBD-II code reader

- Metric wrench and socket sets

- Ratchet and extensions

- Mechanic's stethoscope

- Torx bit set

- Scrrewdriver

- Acetone, electrical parts cleaner, etc.

Step 1 – Scan for diagnostic trouble codes

The first step to diagnosing any performance related problem is to scan the engine control module (ECM) for diagnostic trouble codes (DTC's). Today's vehicles monitor numerous engine parameters to ensure it is operating correctly; however, when a fault is detected, it will often illuminate the check engine light (CEL) and store a related fault code in the computer.

Connect an OBD-II code reader or scan tool to the diagnostic port located under the driver's side dash. With the key in the ON position, scan the ECM for any active or stored fault codes. Reading fault codes can go a long way in helping to pinpoint the source of an engine performance issue.

Pro Tip

If you do not have a code reader handy, most automotive parts stores will scan your vehicle for free.

Step 2 – Air filter

When experiencing a loss of engine power, most individuals jump to the conclusion that some sort of major mechanical component is failing and causing the truck to run poorly. In reality, a simple maintenance item like a dirty air filter can be the reason behind why your truck has lost its pep. An engine ingests a ton of air, especially under load, and if the air filter is clogged, the engine will struggle to breathe and less fuel will be injected to compensate for the lack of air. While a dirty air filter will not likely trigger a CEL, it will definitely hamper engine performance. The air filter can be inspected and replaced in a matter of minutes, and will definitely restore power if the filter element was plugged. For additional information on replacing your air filter, see How to Replace Air Filter.

Step 3 – Spark plugs and coils

Performance issues that are associated with engine misfires often involve the spark plugs and coils. As with any gasoline-powered engine, spark plugs have a finite lifespan and their ability to properly ignite the air-fuel mixture will not last forever. As spark plugs age, carbon deposits can form on the ground straps, electrodes, and insulators, thus causing arcing issues. Similarly, the electrode tends to wear away with use and the spark plug gap can greatly increase. These spark plug issues will cause the individual coils to work harder to ignite the spark plugs, as the coils must supply additional voltage to overcome the excessive resistance of each spark plug. These additional stresses have been known to cause coil failures. Additionally, coils have been known to crack and split over time from being exposed from high underhood temperatures. Spark plugs and coils tend to last thousands of miles, but all it takes is one bad egg to cause engine performance issues. So if you are experiencing a rough idle, poor fuel economy, or even a cylinder misfire(s), inspect the spark plugs and individual coils and replace as necessary. See How to Replace Spark Plugs and Ignition Coils for additional information.

Pro Tip

A number of aftermarket coils have been known to cause CEL's and misfires. Do your research before buying because budget coils may end up costing you more in the long run.

Step 4 – Mass airflow sensor and throttle body

The mass airflow sensor (MAF) measures the air entering the intake and forwards the information to the ECM for proper fueling adjustments. The MAF is of a hot-wire design, which heats a small wire that is cooled by the air passing over it. The voltage of the sensor varies depending on the temperature of the wire, which allows the ECM to monitor intake airflow. Unfortunately, MAF sensors have a tendency to become contaminated, especially on vehicles fitted with oiled aftermarket high-flow air filters, and are unable to properly monitor the intake airflow. The MAF can easily be removed and cleaned with a suitable electrical parts cleaner; however, if the problem persists, the MAF should be replaced. For best engine performance, most agree that the MAF should be replaced every 60,000 miles.

The throttle body has also been known to cause performance issues when it is dirty. With today's advanced emission and exhaust gas re-circulation systems, the throttle body has the tendency to accrue carbon buildup and effect airflow through the butterfly valve. While a dirty throttle body typically causes idle and low speed drive-ability issues, it can also have an affect on performance and throttle response. The throttle body can be easily cleaned by removing the intake tube and using mineral spirits such as acetone or brake parts cleaner. It can be cleaned while attached to the intake manifold, but most agree that a thorough cleaning can only be accomplished by removing the throttle body from the intake manifold.

Pro Tip

It is always a good idea to check for vacuum leaks after the MAF and around the throttle body. Any additional air ingested into the engine that is not measured by the MAF can negatively affect the air-fuel mixture and cause poor engine performance.

Step 5 – Oxygen sensors

The upstream oxygen sensors are perhaps some of the most important components in any fuel-injection system. In previous years, Toyota used narrow-band O2 sensors that were fairly inaccurate, as they only indicated whether the air-fuel ratio was rich or lean. Since, Toyota as well as many other manufacturers have been using wide-band O2 sensors that accurately measure the true air-fuel ratio at all times instead of a only a rich or lean condition. Not to be confused with the post-catalytic O2 sensors that monitor catalyst operation, the upstream O2 sensors are constantly measuring the exhaust gases to allow the ECM to maintain a proper 14.7:1 fuel mixture. As with most components, the O2 sensors tend to age with use and can become lethargic in their measurements. A sensor that is acting up may not always trigger a CEL, because it is still operating within the acceptable specifications set by the ECM, but it can definitely affect engine performance. Similar to the MAF sensor, most mechanics and performance enthusiast agree that the O2 sensors are best replaced around the 60-80,000 mile mark to maintain vehicle performance. For additional information on replacing your O2 sensors, see How to Replace Oxygen (O2) Sensors.

Pro Tip

Tundra's have been known to have problems with their O2 sensors. In fact, Toyota at one time had issued a technical service bulletin for O2 sensor related issues on first generation Tundras.

Step 6 – Exhaust leaks

A number of Tundras find their way to the shop each year because of exhaust leaks. Factory manifolds have been known to crack and allow escaping gases to cause a constant tick, especially under acceleration. This is not a superficial problem, but can hinder performance, and in severe cases, damage engine components. A minor exhaust leak near the manifold (before the O2 sensors) can throw O2 sensor readings off because of the additional air that is sucked into the system. Exhaust leaks tend to cause a loss of low-end performance since there is less back-pressure in the system. A severe leak can cool the exhaust valves very quickly and cause warping, so do not delay on fixing the problem. A quick visual inspection of the exhaust system can indicate if there are any leaks caused by cracks or splits in the manifold. Additionally, a mechanic's stethoscope or length of hose can be used to listen for leaks during a cold engine start-up.

Related Discussions

- Throttle Body Cleaning = Must Do! - YotaTech.com

- HELP...Misfire On All Cylinders - YotaTech.com

- Idle Problem...Please Help! - YotaTech.com