Marlin Crawler EcoSeal Tech Article

#1

Registered User

Thread Starter

Marlin Crawler EcoSeal Tech Article

We have now sold more than 30,000 inner axle EcoSeals, so we thought we'd celebrate by writing an updated tech article and by putting the EcoSeals up as the weekly special product. Please see our Weekly Special Thread more details on this really great offer: https://www.yotatech.com/forums/f37/...ecials-230425/ Help us celebrate this great milestone for our EcoSeal and prevent oil leaks on your truck at the same time!

Marlin Crawler EcoSeal Tech Article (post 1 of 2)

We are extremely proud to offer the best Toyota inner axle seal on the planet. Highly endorsed by numerous organizations, the Marlin Crawler EcoSeal has proven to stop leaks in nearly every continent on the planet. From frozen and dry winters to humid and hot summers, nothing out performs the Marlin Crawler EcoSeal.

This article covers the following aspects of our EcoSeal:

1. It is recommended and fully endorsed by the 4WD Toyota Community.

2. It's solid hoop retainer outperforms garter springs that are easily deformed.

3. It's expansion gap maintains preload regardless of its orientation and deflection direction.

4. It's nitrile sealing ring glues seal in place and fills deep surface scars for long lasting leak-free performance.

5. It's metal casing follows Toyota's design principles and reliability.

6. It's dual sealing lips prevent heavy debris from interfering with the primary seal.

7. It's hydrodynamic helix pump stabilizes seal and improves performance at high speeds.

8. It's self-aligning flange makes installation easy and ensures high performance.

9. It has a long history and worldwide exposure of keeping roads and trails clean from oil leaks.

Accredited Performance

The EcoSeal is endorsed and recommended by every leading 4WD organization in our industry. Many of the current and past presidents of these organizations run EcoSeals in their personal rigs.

Keeping Pressure on the Axle Shaft

When we created our EcoSeal back in 2004, we experimented with numerous designs including springs, ties, and straps. Because these choices lacked structure and could easily be reshaped, a better solution was needed. Marlin's mind went to work and created a solid hoop which maintains its circular shape regardless of pressure.

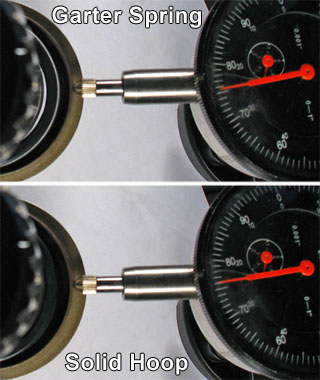

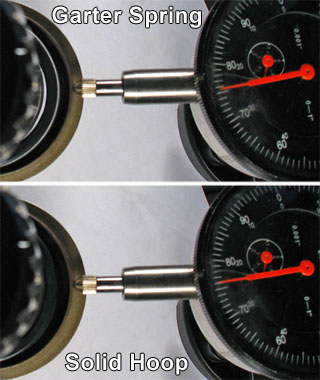

The below image shows how the stock garter spring is unable to hold the rubber against the axle. In contrast, the solid hoop pulls on the seal keeping it as close to the axle as possible. Notice how the solid hoop keeps the rubber sealed against the axle at the same deflection distance.

Why we do not use the stock garter spring:

Why we instead use a Solid Hoop:

The Hoop's solid construction plus its constant pressure results in the best sealing performance available.

To further illustrate the advantage of using a structured solid hoop instead of an easy to reshape spring, we took an undersized socket to show how the spring turns into an oval shape under pressure.

Some customers notice how our hoop has an expansion gap that is movable with their finger. This is normal, the gap is designed to expand and preload the axle shaft once installed.

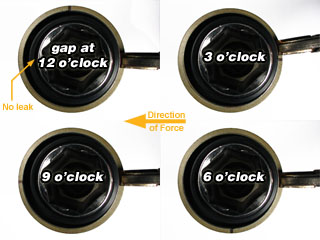

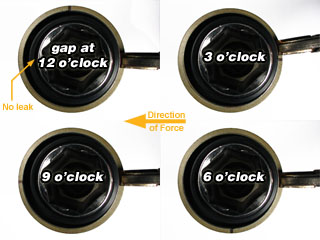

Another great feature of the solid hoop is that it out performs the garter spring regardless of its orientation. The gap in the hoop expands and preloads the axle shaft, maintaining a constant pressure regardless of the deflection direction. In the below images, note how the hoop preloads and preserves the seal in four distinct directions.

Nitrile Sealing Ring

The EcoSeal features an outer nitrile sealing ring, which is an industry standard method to seal the exterior space around seals. Used in automotive applications for more than 50 years, it is the highest performing and most reliable exterior seal available. It is important to have a good outer seal because broken axles and birfields often damage axle housings, resulting in deep scars, gouges, and cuts. Our nitrile ring scrapes off the seal during installation filling into holes and surface imperfections along the way. Additionally, the nitrile has adhesive properties that hold and "glue" the seal in place for long lasting performance! Keep your gear oil where it belongs!

Why a Nitrile ring delivers the best performance:

Dual Sealing Lips with a Bidirectional Helix Pump

For those who enjoy water fording and mud bogging, this is the seal for you. We've incorporated a bidirectional double helix hydrodynamic pump to keep oil in and water out. The double helix molding adds a hydrodynamic pumping force to the knuckle side of the seal, increasing seal efficiency while haulin' the mail through your favorite mud pit. And if any mud or heavy debris finds its way into your knuckle, we've added a secondary outer sealing lip so the primary seal lip can focus on what it does best.

Dual Sealing Lips:

Helix Hydrodynamic Pump:

Marlin Crawler EcoSeal Tech Article (post 1 of 2)

We are extremely proud to offer the best Toyota inner axle seal on the planet. Highly endorsed by numerous organizations, the Marlin Crawler EcoSeal has proven to stop leaks in nearly every continent on the planet. From frozen and dry winters to humid and hot summers, nothing out performs the Marlin Crawler EcoSeal.

This article covers the following aspects of our EcoSeal:

1. It is recommended and fully endorsed by the 4WD Toyota Community.

2. It's solid hoop retainer outperforms garter springs that are easily deformed.

3. It's expansion gap maintains preload regardless of its orientation and deflection direction.

4. It's nitrile sealing ring glues seal in place and fills deep surface scars for long lasting leak-free performance.

5. It's metal casing follows Toyota's design principles and reliability.

6. It's dual sealing lips prevent heavy debris from interfering with the primary seal.

7. It's hydrodynamic helix pump stabilizes seal and improves performance at high speeds.

8. It's self-aligning flange makes installation easy and ensures high performance.

9. It has a long history and worldwide exposure of keeping roads and trails clean from oil leaks.

Accredited Performance

The EcoSeal is endorsed and recommended by every leading 4WD organization in our industry. Many of the current and past presidents of these organizations run EcoSeals in their personal rigs.

Keeping Pressure on the Axle Shaft

When we created our EcoSeal back in 2004, we experimented with numerous designs including springs, ties, and straps. Because these choices lacked structure and could easily be reshaped, a better solution was needed. Marlin's mind went to work and created a solid hoop which maintains its circular shape regardless of pressure.

The below image shows how the stock garter spring is unable to hold the rubber against the axle. In contrast, the solid hoop pulls on the seal keeping it as close to the axle as possible. Notice how the solid hoop keeps the rubber sealed against the axle at the same deflection distance.

Why we do not use the stock garter spring:

- Garter spring stretches and looses contact

- Springs deform and loose their shape

- Does not keep rubber against axle

- Higher risk for oil leak

Why we instead use a Solid Hoop:

- Pulls rubber into the axle

- Applies a constant pressure

- Maintains solid circular shape & seal

- Maximum sealing effectiveness

The Hoop's solid construction plus its constant pressure results in the best sealing performance available.

To further illustrate the advantage of using a structured solid hoop instead of an easy to reshape spring, we took an undersized socket to show how the spring turns into an oval shape under pressure.

Some customers notice how our hoop has an expansion gap that is movable with their finger. This is normal, the gap is designed to expand and preload the axle shaft once installed.

Another great feature of the solid hoop is that it out performs the garter spring regardless of its orientation. The gap in the hoop expands and preloads the axle shaft, maintaining a constant pressure regardless of the deflection direction. In the below images, note how the hoop preloads and preserves the seal in four distinct directions.

Nitrile Sealing Ring

The EcoSeal features an outer nitrile sealing ring, which is an industry standard method to seal the exterior space around seals. Used in automotive applications for more than 50 years, it is the highest performing and most reliable exterior seal available. It is important to have a good outer seal because broken axles and birfields often damage axle housings, resulting in deep scars, gouges, and cuts. Our nitrile ring scrapes off the seal during installation filling into holes and surface imperfections along the way. Additionally, the nitrile has adhesive properties that hold and "glue" the seal in place for long lasting performance! Keep your gear oil where it belongs!

Why a Nitrile ring delivers the best performance:

- Scrapes off and squishes into cavities

- Fills in surface dents and imperfections

- Glues the seal in place for lasting performance

- Industry standard practice for more than 50 years

Dual Sealing Lips with a Bidirectional Helix Pump

For those who enjoy water fording and mud bogging, this is the seal for you. We've incorporated a bidirectional double helix hydrodynamic pump to keep oil in and water out. The double helix molding adds a hydrodynamic pumping force to the knuckle side of the seal, increasing seal efficiency while haulin' the mail through your favorite mud pit. And if any mud or heavy debris finds its way into your knuckle, we've added a secondary outer sealing lip so the primary seal lip can focus on what it does best.

Dual Sealing Lips:

- Adds an additional barrier

- Keeps heavy debris away from the primary seal

- Provides a huge reservoir for packing grease during installation

- Helps spread forces across seal flange

- Standard EcoSeal feature for more than half a decade

Helix Hydrodynamic Pump:

- Improves sealing performance at higher speeds

- Hydrodynamic force stabilizes the seal contact area

- Forces oil seepage back into the axle housing

- Improved performance moving forward or in reverse

Last edited by BigMike; 05-08-2011 at 09:06 AM.

#2

Registered User

Thread Starter

Marlin Crawler EcoSeal Tech Article (post 2 of 2)

We make both rubber coated and bare steel EcoSeals. Which is right?

We make 7 different EcoSeals in both bare steel and rubber coated versions. Just like Toyota, we use rubber coated seals for aluminum housings and steel seals for steel housings. Aluminum has nearly double the thermal expansion rate as steel, and rubber coated seals depend on this expansion in order to remain seated in place. Moreover, axle housings that are damaged from prior axle failure will easily cut rubber coatings resulting in a leaking rubber seal.

Why we and Toyota do not use rubber coated seals for axle housings:

Self-aligning flange: An installer's best friend

The EcoSeal uses a large metal flange making installation a cinch. The stock seal does not have a flange, and therefore careful attention must be done during installation: If the seal is installed too shallow or deep, or even worse, crooked, then it may not be effective at sealing at all. In contrast, the large flange on our EcoSeal does all the aligning for you. It positions the EcoSeal at just the right depth each time, and always mounts flush to the axle housing. The flange self-aligns the two sealing lips perfectly with the axle shaft. Oil leaks stand no chance with the EcoSeal!

Large Steel Flange:

The numbers don't lie

We have sold over 30,000 front inner axle seals to 6 continents. From Alaska to Chile, Iceland to South Africa, and Russia to Tasmania, our front inner axle EcoSeal has been keeping the planet clean and clear from oil leaks since 2005!

Build your truck with confidence:

Designed to Outperform

Thank you for learning about our EcoSeal. We hope you'll agree that our EcoSeal is designed to be the best performing Toyota inner axle seal in the world, and that you will help us keep trails oil free by putting our EcoSeal technology and performance to work for you!

Regards,

BigMike

Marlin Crawler, Inc.

We make both rubber coated and bare steel EcoSeals. Which is right?

We make 7 different EcoSeals in both bare steel and rubber coated versions. Just like Toyota, we use rubber coated seals for aluminum housings and steel seals for steel housings. Aluminum has nearly double the thermal expansion rate as steel, and rubber coated seals depend on this expansion in order to remain seated in place. Moreover, axle housings that are damaged from prior axle failure will easily cut rubber coatings resulting in a leaking rubber seal.

Why we and Toyota do not use rubber coated seals for axle housings:

- Rubber coated seals are designed for high thermal expansion aluminum housings

- Rubber coated seals become loose if used in a steel housing

- High risk of seal backing out of housing resulting in complete failure

- High risk of cut rubber due to common housing damage

Self-aligning flange: An installer's best friend

The EcoSeal uses a large metal flange making installation a cinch. The stock seal does not have a flange, and therefore careful attention must be done during installation: If the seal is installed too shallow or deep, or even worse, crooked, then it may not be effective at sealing at all. In contrast, the large flange on our EcoSeal does all the aligning for you. It positions the EcoSeal at just the right depth each time, and always mounts flush to the axle housing. The flange self-aligns the two sealing lips perfectly with the axle shaft. Oil leaks stand no chance with the EcoSeal!

Large Steel Flange:

- Self-aligns both sealing lips for perfect contact with axle shaft

- Prevents seal from being installed crooked

- Prevents seal from being installed too shallow or deep

- Makes installation as easy as pie

- Consistent, worry free performance right from the beginning

- Easy and fast installation every time

The numbers don't lie

We have sold over 30,000 front inner axle seals to 6 continents. From Alaska to Chile, Iceland to South Africa, and Russia to Tasmania, our front inner axle EcoSeal has been keeping the planet clean and clear from oil leaks since 2005!

Build your truck with confidence:

- The only aftermarket seal that is fully endorsed by leading 4WD organizations

- Performance that lasts, and lasts, and lasts

- Proven to stop leaks the whole world over

- No climate is too harsh for the EcoSeal

Designed to Outperform

Thank you for learning about our EcoSeal. We hope you'll agree that our EcoSeal is designed to be the best performing Toyota inner axle seal in the world, and that you will help us keep trails oil free by putting our EcoSeal technology and performance to work for you!

Regards,

BigMike

Marlin Crawler, Inc.

Thread

Thread Starter

Forum

Replies

Last Post

smilen724

86-95 Trucks & 4Runners (Build-Up Section)

13

11-08-2015 04:11 PM

FS[SouthCent]: TX - 4Crawler Ball Joint spacers

crash813

Axles - Suspensions - Tires - Wheels

0

09-27-2015 07:15 AM

Toys4parts

86-95 Trucks & 4Runners (Build-Up Section)

2

09-26-2015 01:56 PM

FS[PacNorWest]: 1987 4Runner SAS, 22RE, 5Spd, Dual Cases, etc

toyotasaurus

Vehicles - Trailers (Complete)

0

09-24-2015 03:30 PM