Low Profile Cargo Box 3rd Gen

#84

#85

Good idea, better then nothing that is for sure. I know that i alwas have stuff int he back of my truck so having to unload all of that to get tot he stuff in this would be a pain.

#86

Registered User

Joined: Jul 2007

Posts: 1,705

Likes: 10

From: Yotatech, because Pirate is too expensive. NorCal.

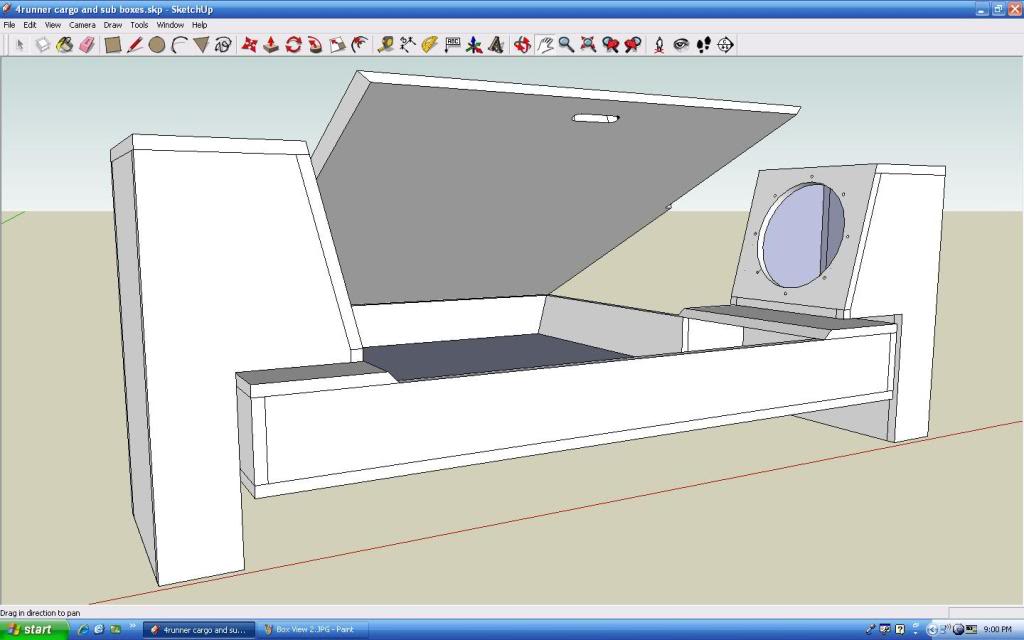

Im going to make mine with one big door on the top that is hinged at the back seats. I dont usually have much back there and I dont mind lifting it with stuff on top of it. Only problem I could think of is when I carry my tool box.

#87

When I am tailgaiting or camping the lid of the rear box with the piano hinge opens flat and makes a perfect table for drinks or food or whatever. I'm going to cut out some soda can sized depressions in it with a hole saw to securely hold beverages during such activities.

I have less than $100 invested in making these boxes.

Last edited by DeMented Toys; 05-14-2009 at 04:12 PM.

#88

Yowza!

Y'all sure have done some purty work here.

G----a you are scaring me cutting the aluminum plate with a table saw. Use a skill saw with a carbide blade, set the depth to just peeking out the bottom of the material. Will cut up to 1/4" aluminum plate just fine. Be sure you have a good grip on the saw and if you clamp on a guide strip it helps a lot. You are also gonna want ear plugs. Really really but you already know that I bet. Hey I bet you could also get the shop that broke your metal to shear the sheet for you as well. If you cut your production time down who knows you might be able to make a buck or 10 out of selling these.

Hey I bet you could also get the shop that broke your metal to shear the sheet for you as well. If you cut your production time down who knows you might be able to make a buck or 10 out of selling these.

Here's another source for your slides. These are really pricey but look at the weight rating. Give em a call I'm sure they would have something less expensive in your extension range.

http://www.cabinetparts.com/c/drawer...ides/KV890042/

And for something with half the depth but way less in price, check these out.

http://www.grainger.com/Grainger/items/1PWR4

Y'all keep up the good work

Jim

G----a you are scaring me cutting the aluminum plate with a table saw. Use a skill saw with a carbide blade, set the depth to just peeking out the bottom of the material. Will cut up to 1/4" aluminum plate just fine. Be sure you have a good grip on the saw and if you clamp on a guide strip it helps a lot. You are also gonna want ear plugs. Really really but you already know that I bet.

Hey I bet you could also get the shop that broke your metal to shear the sheet for you as well. If you cut your production time down who knows you might be able to make a buck or 10 out of selling these.

Hey I bet you could also get the shop that broke your metal to shear the sheet for you as well. If you cut your production time down who knows you might be able to make a buck or 10 out of selling these.Here's another source for your slides. These are really pricey but look at the weight rating. Give em a call I'm sure they would have something less expensive in your extension range.

http://www.cabinetparts.com/c/drawer...ides/KV890042/

And for something with half the depth but way less in price, check these out.

http://www.grainger.com/Grainger/items/1PWR4

Y'all keep up the good work

Jim

#89

Y'all sure have done some purty work here.

G----a you are scaring me cutting the aluminum plate with a table saw. Use a skill saw with a carbide blade, set the depth to just peeking out the bottom of the material. Will cut up to 1/4" aluminum plate just fine. Be sure you have a good grip on the saw and if you clamp on a guide strip it helps a lot. You are also gonna want ear plugs. Really really but you already know that I bet. Hey I bet you could also get the shop that broke your metal to shear the sheet for you as well. If you cut your production time down who knows you might be able to make a buck or 10 out of selling these.

Hey I bet you could also get the shop that broke your metal to shear the sheet for you as well. If you cut your production time down who knows you might be able to make a buck or 10 out of selling these.

Here's another source for your slides. These are really pricey but look at the weight rating. Give em a call I'm sure they would have something less expensive in your extension range.

Y'all keep up the good work

Jim

G----a you are scaring me cutting the aluminum plate with a table saw. Use a skill saw with a carbide blade, set the depth to just peeking out the bottom of the material. Will cut up to 1/4" aluminum plate just fine. Be sure you have a good grip on the saw and if you clamp on a guide strip it helps a lot. You are also gonna want ear plugs. Really really but you already know that I bet.

Hey I bet you could also get the shop that broke your metal to shear the sheet for you as well. If you cut your production time down who knows you might be able to make a buck or 10 out of selling these.

Hey I bet you could also get the shop that broke your metal to shear the sheet for you as well. If you cut your production time down who knows you might be able to make a buck or 10 out of selling these.Here's another source for your slides. These are really pricey but look at the weight rating. Give em a call I'm sure they would have something less expensive in your extension range.

Y'all keep up the good work

Jim

Thanks for the suggestions for technique and safety. I hear ya. Never can learn enough when it comes from those two. Since you brought up cutting aluminum with a table saw again, for those that might want to use the table saw instead of taking it into a shop, I'd suggest a sharp 80 tooth carbide blade and use wax. You can pick up wax in a cardboard tube that is a combo of bees and paraffin for your blades. It's important to have your blades sharp. I agree with Jim that it's a good idea to take it to a shop and have them do it, no doubt it is safer. The kickback is the really nasty part. Kicking back sheet or plate might as well be a sword. Wood's bad enough but metal is a lot more dangerous. If however you choose to do it anyway keep out of the kickback path and of course use eye and face protection. The noise may not bring you to your knees but it's easy to get metal on metal above 130dB. Instant hearing damage occurs at 110dB. Your ears won't bleed and it won't even hurt that much but the damage does occur and it doesn't show up until years later when you naturally start to lose your hearing anyway. Thanks again for posting up for safety. Like many things in life it takes weighing out the risks. I think about that often when I handle my most lethal machine. It's boss. Weighing in at over 5000lbs capable of creating 30,000 lbs of force at less then 15% of it's top speed. It has with just a minor slip of attention killed cows, people, and smashed though buildings. It's baaaad and I love using it many and often despite the fact that this kind of machine kills over 40,000 Americans every year. Speed kills. Maybe I should invent a table saw that spins at 15 rpm. lol I really do appreciate the comments. I've had freinds show me what I was doing wrong or at least a better way to do things and it probably saved me from loss of limb or even life. I certainly don't know it all!

#90

Registered User

Joined: Jul 2007

Posts: 1,705

Likes: 10

From: Yotatech, because Pirate is too expensive. NorCal.

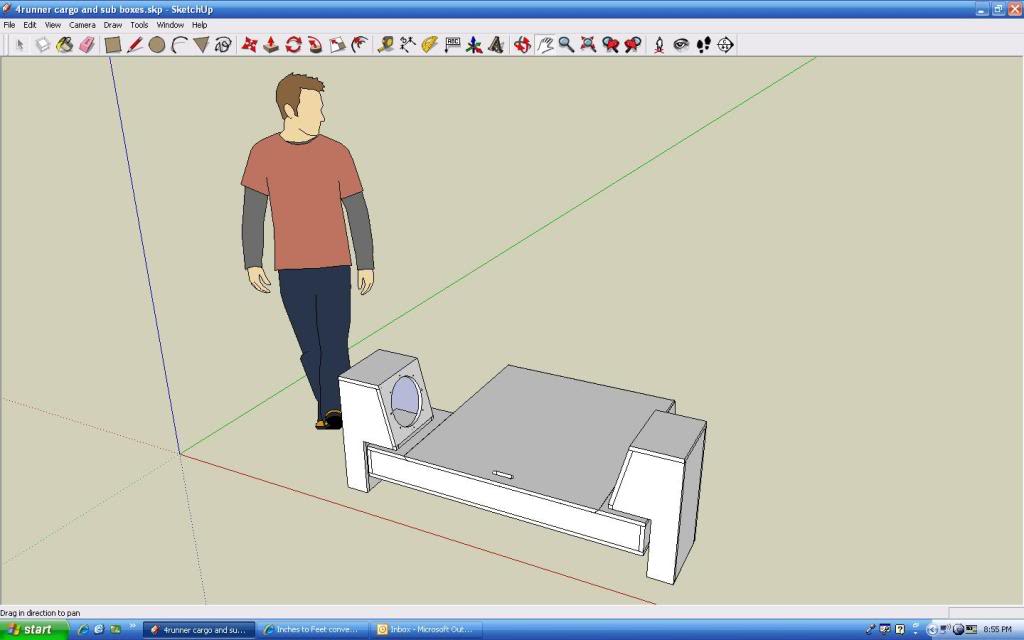

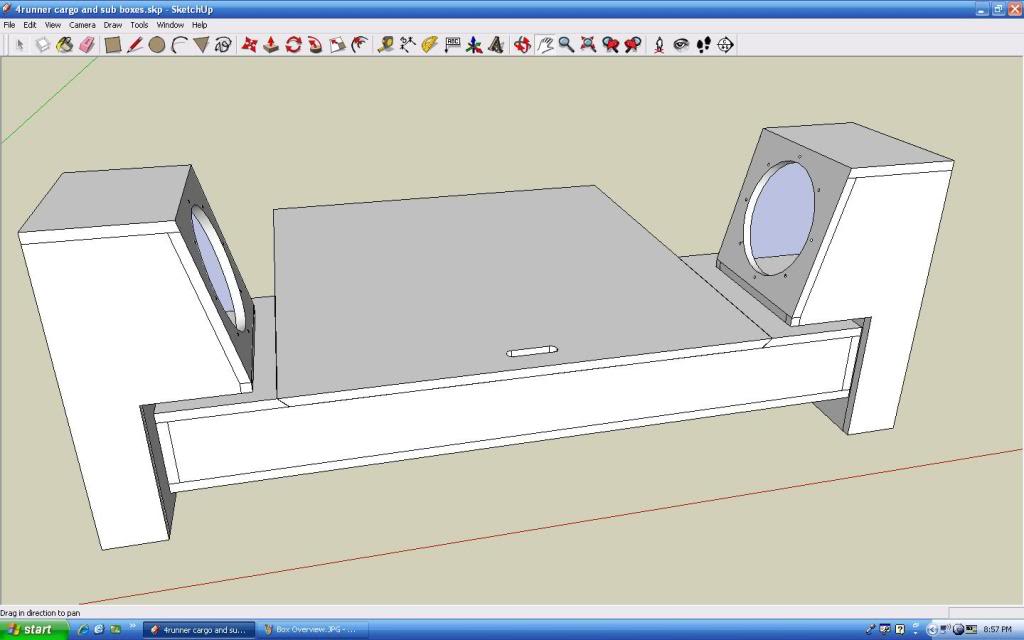

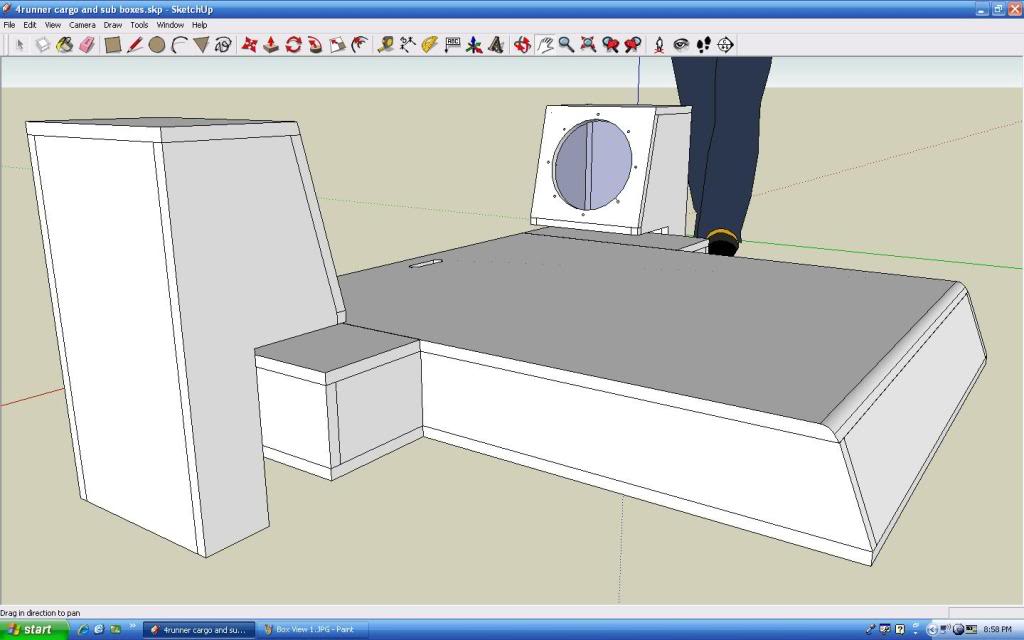

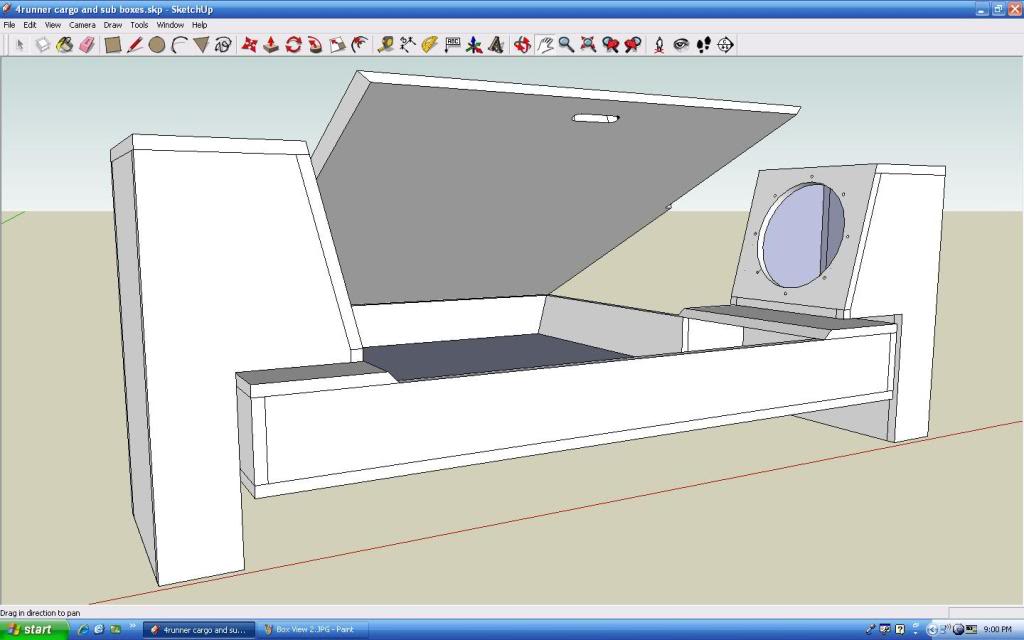

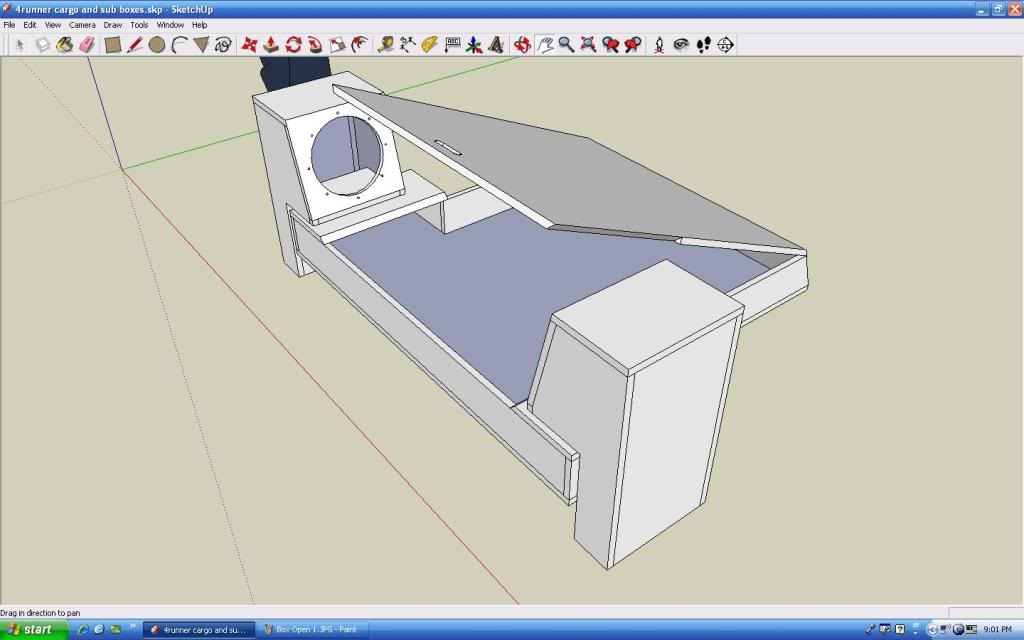

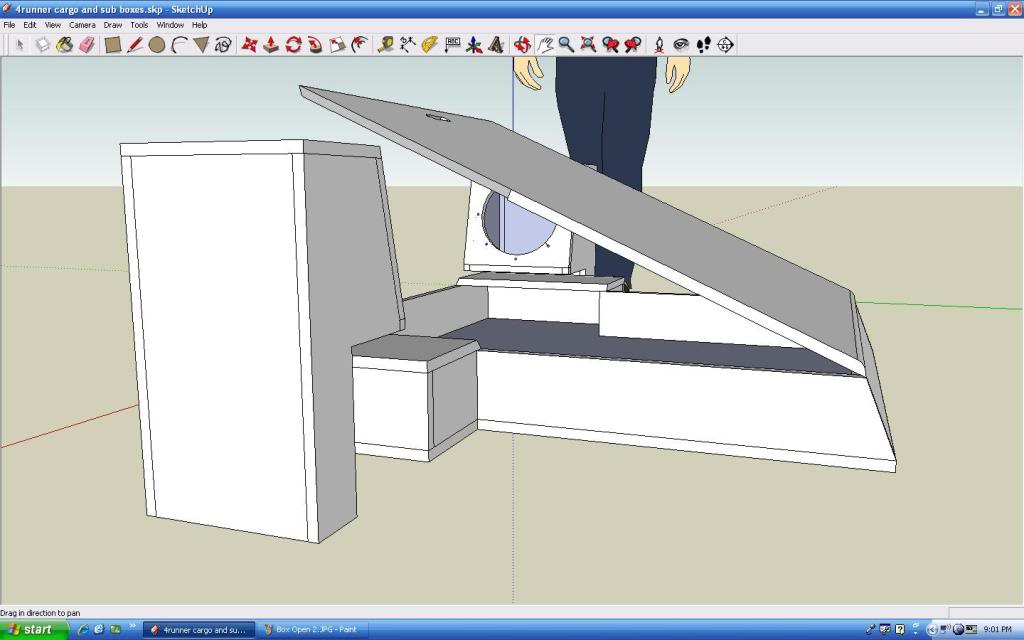

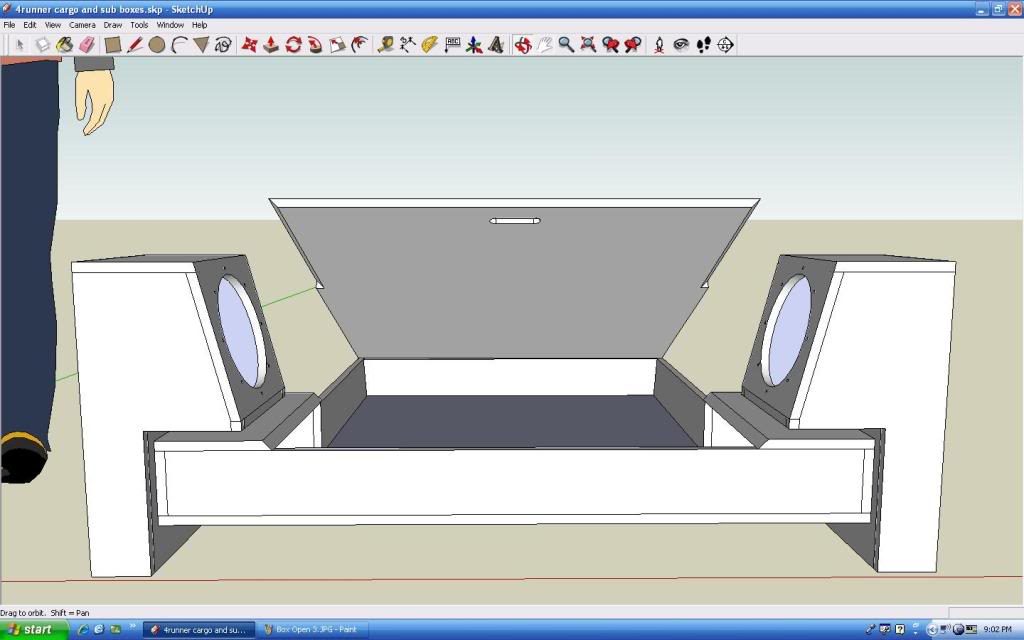

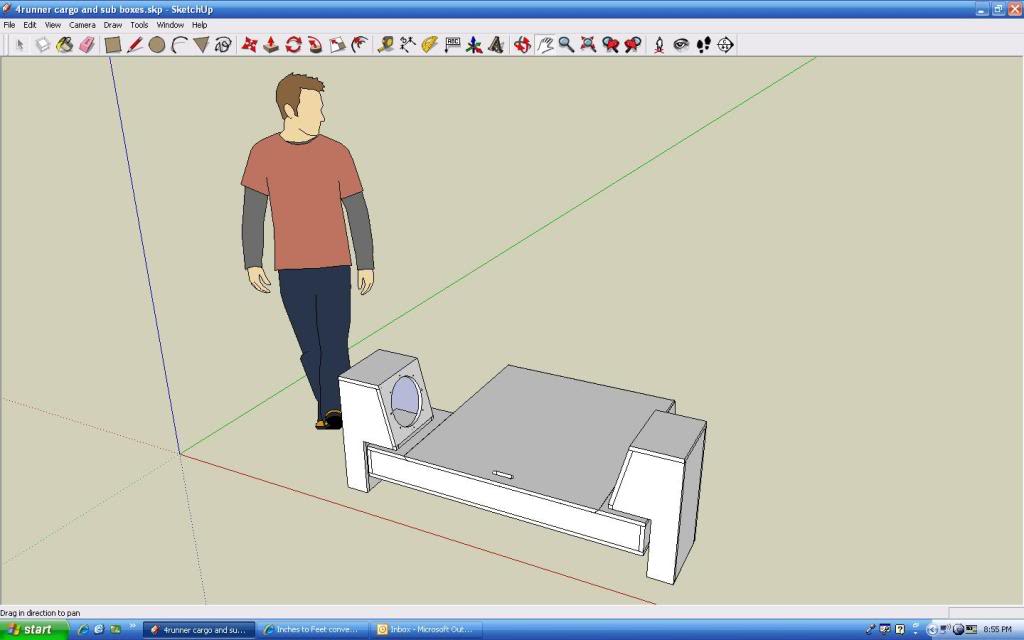

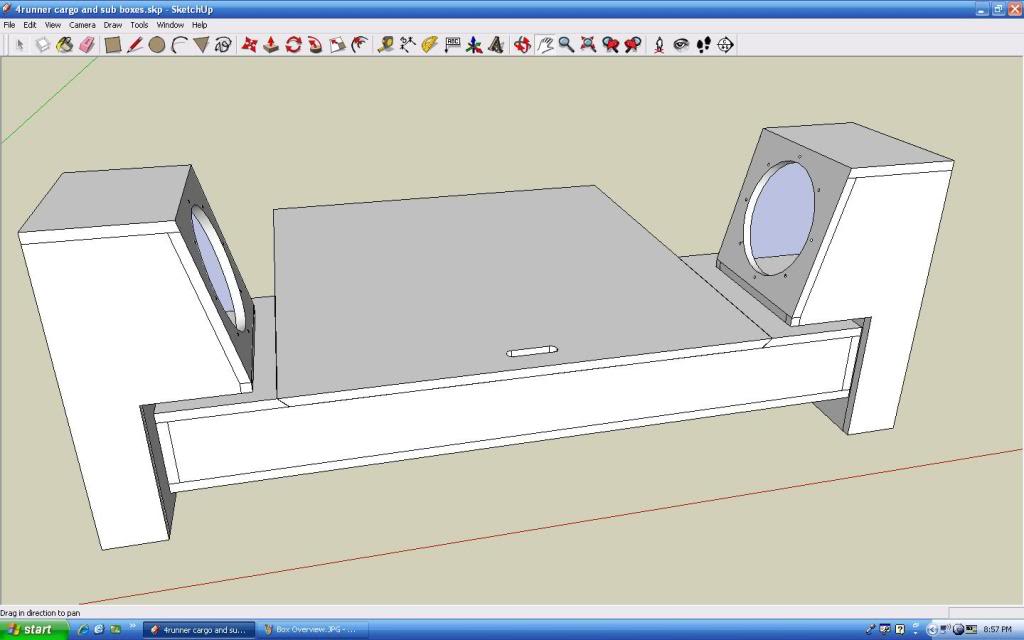

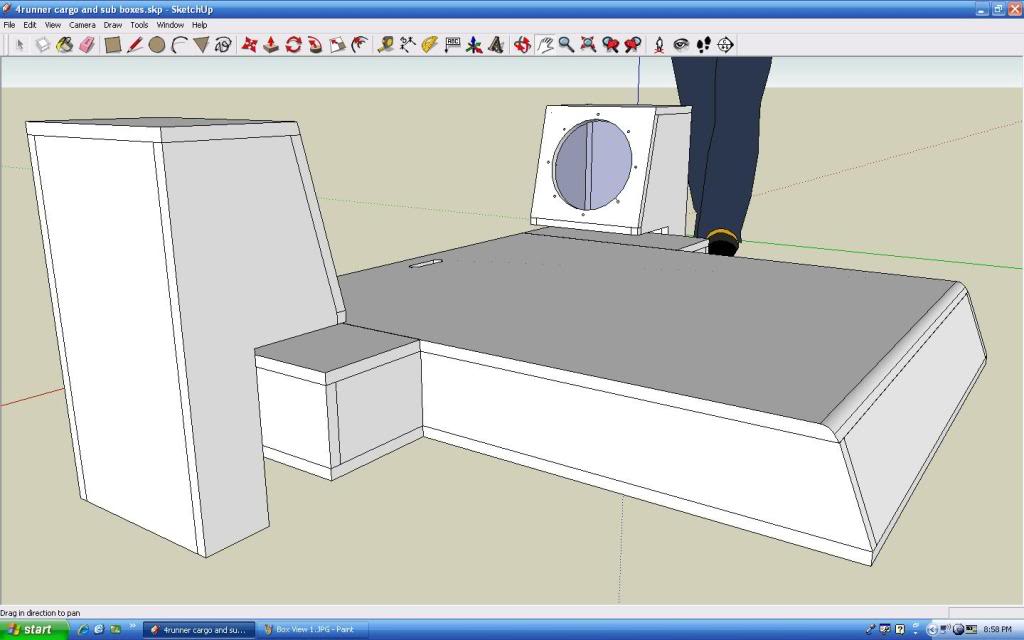

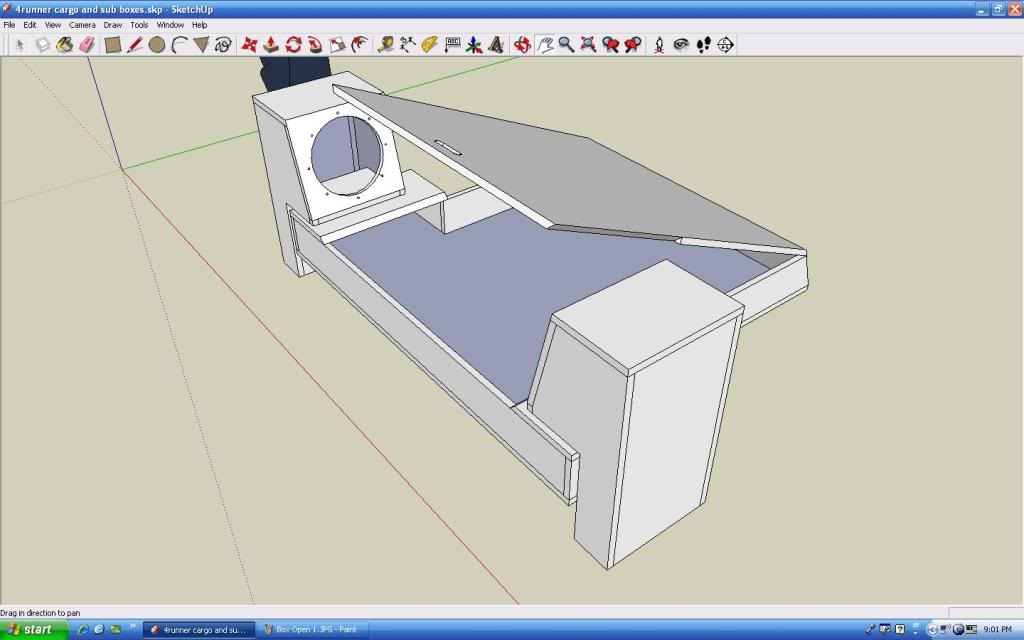

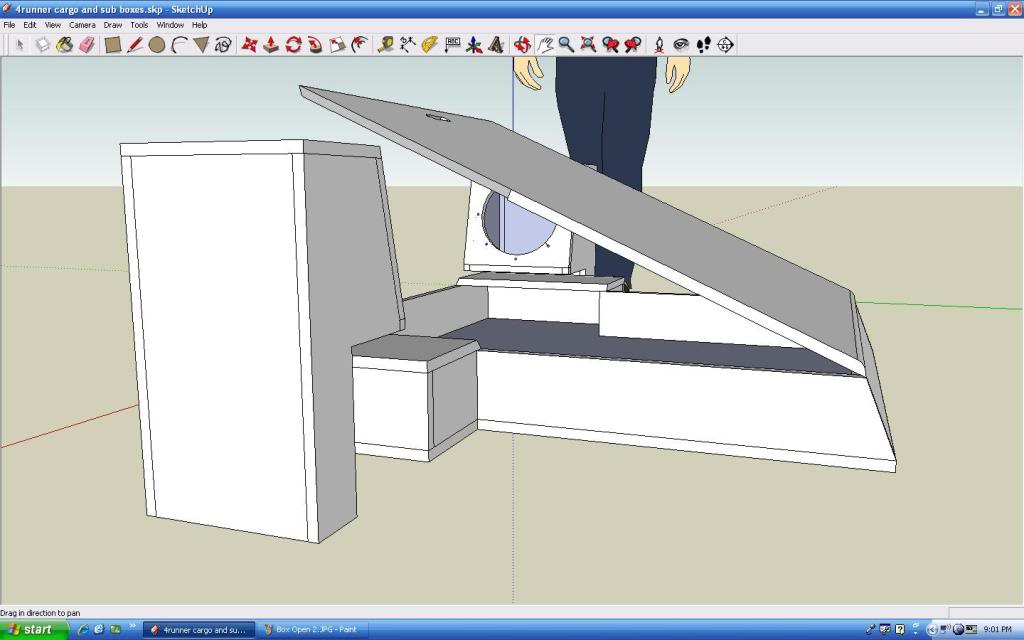

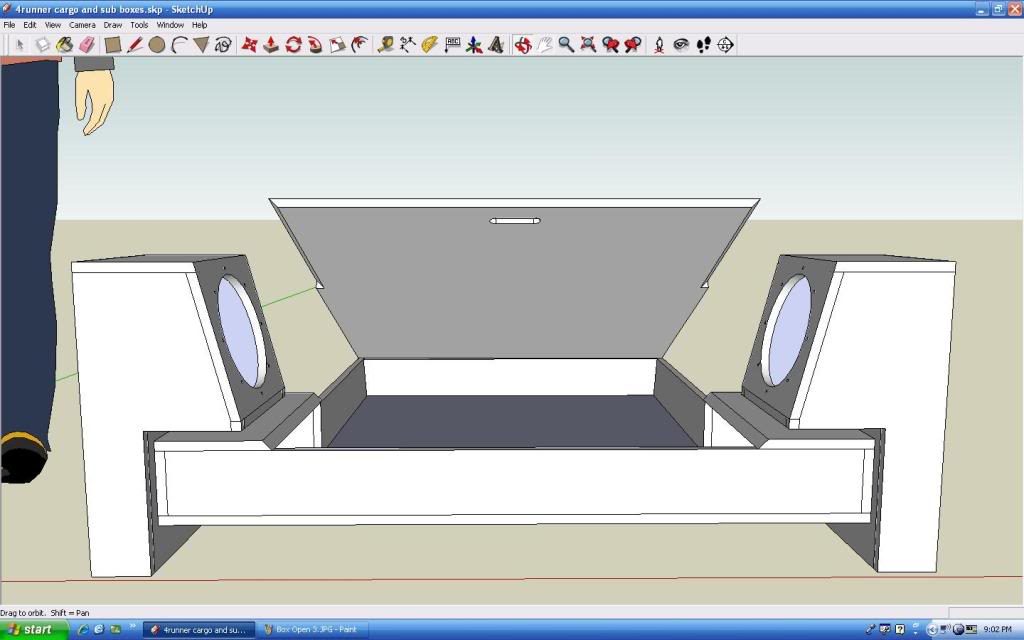

OK so I was bored this afternoon and decided to put my idea into SketchUp. I have a big box with a single lift door on the top and the two on the sides are for a JBL P1022. 10" subs with a 700rms watt JBL amp. They will be sunk into the side cubbyhole things with the plastic trimmed around them. The measurements arent perfect and it will obviously need some changes when I put it into action but for now everything is within 1/2 inch.

Oh yeah and the area around the fender wells will be form fitted to the fender wells like glenyoshida did. I just didnt want to try to draw that out.

Oh yeah and the area around the fender wells will be form fitted to the fender wells like glenyoshida did. I just didnt want to try to draw that out.

Last edited by toylocost; 05-14-2009 at 08:35 PM.

#93

I love this thread, it was one of the first ones I found on the net that brought me to yotatech....it's still bookmarked as my yotatech link from back then...cool to see it still floating around.

it makes me want to get a runner one day. Its also made me think about putting something similar in my bed. there are so many tools and randoms that I bring every trip that it would be nice to have a permanent place for them as to not load unload & repack constantly & having a big mess in the bed or behind my seat. Ive been making a list of essentials and am going to put em all together and measure the space to see how thin I can get it as for taking up bed space. putting an extra 6" on my bed sides might even let me keep the same load space and since I have a soft topper it would be pretty simple to still mount it flush with the cab.

it makes me want to get a runner one day. Its also made me think about putting something similar in my bed. there are so many tools and randoms that I bring every trip that it would be nice to have a permanent place for them as to not load unload & repack constantly & having a big mess in the bed or behind my seat. Ive been making a list of essentials and am going to put em all together and measure the space to see how thin I can get it as for taking up bed space. putting an extra 6" on my bed sides might even let me keep the same load space and since I have a soft topper it would be pretty simple to still mount it flush with the cab.

#94

I make a write-up of how I built my cargo box. It is on E-How if anyone wants to check it out.

http://www.ehow.com/how_5123517_buil...boxes-suv.html

http://www.ehow.com/how_5123517_buil...boxes-suv.html

#96

I bought my drawer rails from this place - it's nice because you can shop by load rating and slide length....

http://www.drawerslides.com/

http://www.drawerslides.com/

Last edited by Mojo_Risin; 07-01-2009 at 01:53 PM.

#98

That is a beauty ! I've sent this page to a bunch of buddies and everyone said you should package that up into a kit and sell it ! I think you would do quite well.

Good Job !

Good Job !

Another Cargo Box idea for ya geared toward expeditioning. I like to camp but don't like setting up and tearing down tents. I built this for my 2001 4Runner.

I got tired of loading and unloading my gear. I think this will help a lot. For reference, the aluminum drawers hold as much as a pair of cargo drawers made of just 3/4" ply that is 8 inches high and 20 inches deep.

The cargo box is low enough for a person about 6 foot and under to sit upright without touching yer head on the ceiling.

Tah Dah! All done.

I got tired of loading and unloading my gear. I think this will help a lot. For reference, the aluminum drawers hold as much as a pair of cargo drawers made of just 3/4" ply that is 8 inches high and 20 inches deep.

The cargo box is low enough for a person about 6 foot and under to sit upright without touching yer head on the ceiling.

Tah Dah! All done.

Last edited by XJeepguy; 11-20-2011 at 10:41 AM.

#100

The tire carrier is going to be sick though when it's done. I'm going to try and get the chainsaw mount on the carrier done this winter.

Last edited by glenyoshida; 11-20-2011 at 09:52 PM.

And I didn't want to spend $200 per drawer slide.

And I didn't want to spend $200 per drawer slide.