Terrys87 86 4Runner with a 2nd Chance

#1981

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

I did Rays Starter Upgrade. Last week Misty had mine at the store and it would not start for her. I showed up and jumped in and it started right up. I asked her if she was turning the key, had the key in the ignition, and even had the keys, lol. It has done this to me before as well so I was just teasing her. I have replaced the Solenoid Contacts and cleaned the Starter Relay Contacts as well and it still will just click every once in awhile. For me I can usually start tapping on things and getting it going. Misty doesnt quite understand how to get around something like that and the clicking issue is frustrating.

I got Ray on the phone and he stepped me thru on doing the upgrade and what all was happening. He did a great job on explaining how the electric flowed that I could understand it. Thanks Ray for your help. I had just gotten anotherrr new phone as I dropped my other new phone and broke it. He had to contend with me trying to learn all of that as well. One time even trying to find the key pad to call back.

If you look at the plug with eyes, mustache and a smile, the one you need to cut is the right side of the mustache as you are looking at it, hehe

What I am trying to show here is the thinnest little black wire with the red stripe is on the left. The wire on the right is the one you want to cut which is diagonally across from the red stripe wire. Going from Left, Top, Right and Bottom, it is the Right one. The wire that I cut and is where my pinky is going to get wrapped back up into the wiring harness and will not be used again.

I eventually want to run a kill switch inside the cab and to do the AFM and Battery Swap. I also have an 82 Supra AFM that I want to install when I do all of that. I feel this will fix the click only issue and Thanks Ray for taking the time to step me thru it.

To try and show how I have it and how it is routed, it comes off of the batttery with a 30 Amp Fuse connector, along fender well to the Starter Relay Plug. I have left the wires loose just for explanation purposes but did route it tighter and cleaner.

I got Ray on the phone and he stepped me thru on doing the upgrade and what all was happening. He did a great job on explaining how the electric flowed that I could understand it. Thanks Ray for your help. I had just gotten anotherrr new phone as I dropped my other new phone and broke it. He had to contend with me trying to learn all of that as well. One time even trying to find the key pad to call back.

If you look at the plug with eyes, mustache and a smile, the one you need to cut is the right side of the mustache as you are looking at it, hehe

What I am trying to show here is the thinnest little black wire with the red stripe is on the left. The wire on the right is the one you want to cut which is diagonally across from the red stripe wire. Going from Left, Top, Right and Bottom, it is the Right one. The wire that I cut and is where my pinky is going to get wrapped back up into the wiring harness and will not be used again.

I eventually want to run a kill switch inside the cab and to do the AFM and Battery Swap. I also have an 82 Supra AFM that I want to install when I do all of that. I feel this will fix the click only issue and Thanks Ray for taking the time to step me thru it.

To try and show how I have it and how it is routed, it comes off of the batttery with a 30 Amp Fuse connector, along fender well to the Starter Relay Plug. I have left the wires loose just for explanation purposes but did route it tighter and cleaner.

Last edited by Terrys87; 11-09-2015 at 03:59 PM.

#1982

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

I installed another TPS on to the 86 extra cab I am working on and it is worse then the original one. I am going to re install the original one and see if I cant set the timing with it and take the truck on a shake down run. What I don't understand is with out the timing jumper, it wont throw a code, with the jumper in, it throws the TPS code. I am hoping a new connector will fix this problem. Got more of the interior back in so am still chugging along. Hopefully the cold weather is out of here for good. But it is heating up quick, but I work with heat over cold.

#1983

Not sure If you guys are getting weather down your way, but it's all clashing up here. In a flash flood and tornado watch till 10 pm tonight.

Said Denver is getting snow!! And my parents live in Moab, UT , sent pictures of hail they got about an hour ago.

Said Denver is getting snow!! And my parents live in Moab, UT , sent pictures of hail they got about an hour ago.

#1984

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

Hello Gizzler00.. We were to get some and we have missed it twice. This is not the time of year that I care for as far as tornado conditions. I have been keeping my cars under cover just to avoid the hail damage. I work 3 miles from where that tornado hit Joplin a few years ago and just recently the town next to Joplin got hit with a tornado. Seems like May, june and some of July can get bad. Use to didnt bother me, but they are getting closer and more dangerous. For as long as I have lived here, I have never seen a tornado. I have seen the effects of them numerous times. They do some strange things.

#1985

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

Last nite I was driving Mistys runner and the clutch slave cylinder went out half way to work. Luckily I can drive with out a clutch so got to work and back home with no problems. I got a parts store replacement slave cylinder and it is from China. I will be getting one from Aisian off of the internet and get it on as soon as possible. The China one did make the pedal stiffer and seems to be working great, but China stuff just has me concerned for the long run. Another time I had a slave cylinder to go out and it too did not give me any warnings of getting ready to just quit. Guess the seals just give out all at once.

I stuck another TPS on the 86 truck and still the same results. I am thinking it is the connector and will be getting one off of a guy I know in the next day or so. Until then I am going to actually run test on it and see if I can find any reason to suspect the TPS. I have only had one to fail before and I just swapped the whole assembly out and never had any issues.

I actually am getting out the FSM to troubleshoot this one. Usually a Haynes Manual gets me thru a problem. I did find some differences on the different styles of Throttle Body Assemblys and you can just move parts from one to another. I will post pics on that later. It is set up quite nice and easy to do.

I am getting a Code 11. It wont flash any codes at all except for a Code 1 which means all is good. The second I hit the throttle, it starts flashing 11. The other issue a Code 11 is the AC Switch. I swapped it out with another one and double checked all connections and made sure they were good and cleaned. Problems like these just make you learn it that much more better. I will be digging thru the web and 4Crawlers site as well. Will post up what I find.

http://www.4crawler.com/4x4/CheapTricks/TPS/index.shtml

http://www.mr2oc.com/showthread.php?t=510522

I stuck another TPS on the 86 truck and still the same results. I am thinking it is the connector and will be getting one off of a guy I know in the next day or so. Until then I am going to actually run test on it and see if I can find any reason to suspect the TPS. I have only had one to fail before and I just swapped the whole assembly out and never had any issues.

I actually am getting out the FSM to troubleshoot this one. Usually a Haynes Manual gets me thru a problem. I did find some differences on the different styles of Throttle Body Assemblys and you can just move parts from one to another. I will post pics on that later. It is set up quite nice and easy to do.

I am getting a Code 11. It wont flash any codes at all except for a Code 1 which means all is good. The second I hit the throttle, it starts flashing 11. The other issue a Code 11 is the AC Switch. I swapped it out with another one and double checked all connections and made sure they were good and cleaned. Problems like these just make you learn it that much more better. I will be digging thru the web and 4Crawlers site as well. Will post up what I find.

http://www.4crawler.com/4x4/CheapTricks/TPS/index.shtml

http://www.mr2oc.com/showthread.php?t=510522

Last edited by Terrys87; 05-13-2014 at 02:27 AM.

#1986

G58 Tranny Rebuild

My transmission is sitting on my deck and I am about to attempt to rebuild it. Any suggestions? havent found a thread about rebuilding trannys here, but if there is one i'd like to know... any ideas what size bearing puller I would need? Are full rebuild kits the way to go, or should i just crack it open and see whats bad? Thanks

Ash

(92 pickup 22re 4x4 extended cab)

Ash

(92 pickup 22re 4x4 extended cab)

Last edited by ashmerlin; 05-16-2014 at 12:15 PM.

#1987

My transmission is sitting on my deck and I am about to attempt to rebuild it. Any suggestions? havent found a thread about rebuilding trannys here, but if there is one i'd like to know... any ideas what size bearing puller I would need? Are full rebuild kits the way to go, or should i just crack it open and see whats bad? Thanks

Ash

(92 pickup 22re 4x4 extended cab)

Ash

(92 pickup 22re 4x4 extended cab)

pictures PICTURES take LOTS of pictures

#1988

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

Hello Ash.. Welcome to Yotatech. I haven't rebuilt one myself but am going to give it a try one day. As far as cost, a complete rebuild kit is close enough that it would be wiser to buy one from Marlin Crawler in my opinion. When I do attempt to do it, I will buy a seal kit and maybe one or two other parts that I may need to do it. Here is a link to a thread that would help to see what all is involved. https://www.yotatech.com/forums/f116...thread-219038/

I just want to see if I can do it as well. I don't think it is hard as it may be lead on to believe. I would suggest getting a gear puller with some long jaws on them to pull the gears. I understand a Harbor Freight press will do the job for pressing gears on with some modifications as well.

Marlin Crawler sells a tranny for about $850 plus shipping and a core. Around here the salvages want $5-600 for one. For that cost you may as well get one from a company that you can trust. He sells pars as well. I find trannys off of Craigslist for a lot less.

If you do decide to build a transmission, start a thread on it. I would enjoy following along. I too have searched and haven't really found an in depth thread on something like that. I eventually will get to learning on one but I think it is going to be a winter time project when I get to it.

I just want to see if I can do it as well. I don't think it is hard as it may be lead on to believe. I would suggest getting a gear puller with some long jaws on them to pull the gears. I understand a Harbor Freight press will do the job for pressing gears on with some modifications as well.

Marlin Crawler sells a tranny for about $850 plus shipping and a core. Around here the salvages want $5-600 for one. For that cost you may as well get one from a company that you can trust. He sells pars as well. I find trannys off of Craigslist for a lot less.

If you do decide to build a transmission, start a thread on it. I would enjoy following along. I too have searched and haven't really found an in depth thread on something like that. I eventually will get to learning on one but I think it is going to be a winter time project when I get to it.

#1989

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

Hello cyberhorn.. My FSM shows how to build one and you are right, it would be needed. I would like to find a CD or something that would show more info on it. The FSM has info but not the best pictures. I am starting to feel like I could do it eventually.

#1990

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

I have tested 5 different Throttle Position Sensors and using the FSM and 4Crawlers information which is basically the same, none of them have come in with the same readings as what is mentioned in the test procedures. I am going to test Mistys and my TPS here in the next few days to see what the numbers on them. I cant see 5 all being bad as I know a couple did come off of running trucks. I am leaving a little leeway for the numbers so I am not getting that strict on the numbers.

I did go buy a new feeler gauge and the test says .0224 my gauge is .022, in my opinion the .0004 would be dealing with something like the thickness of a hair and shouldn't make a difference as it is so small. Do I need to find a feeler gauge that goes that small??? Where would I find one that small???

I did go buy a new feeler gauge and the test says .0224 my gauge is .022, in my opinion the .0004 would be dealing with something like the thickness of a hair and shouldn't make a difference as it is so small. Do I need to find a feeler gauge that goes that small??? Where would I find one that small???

#1991

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

We have gotten cold for a while but looks like we are having warmer days a coming. Mid May and it has been cool. Go figure??? Been getting a lot of small things done that don't really show but is time consuming. Still chugging along.

Have spent sometime on several other things when we have warm days and is nice being out of the house. I always thought hernias was a groin related injury and guess they aren't. Justin apparently has a hernia in his stomach area. Find out later if he gets surgery or not. That kid has beaten me in all of the hospital things. I broke my first bone at 18, he broke his arm around 9, I got my first stitches at 13, he has been stitched up twice before he was 9. I think he has beaten me on some other things as well just cant recall what they are. I think it is because they have so much more activities that we didn't have when younger like extreme skating and biking. Yeah !!! when he gets to that stage. We have to slow him down sometimes but sure has pulled a few stunts that we don't know of.

Have spent sometime on several other things when we have warm days and is nice being out of the house. I always thought hernias was a groin related injury and guess they aren't. Justin apparently has a hernia in his stomach area. Find out later if he gets surgery or not. That kid has beaten me in all of the hospital things. I broke my first bone at 18, he broke his arm around 9, I got my first stitches at 13, he has been stitched up twice before he was 9. I think he has beaten me on some other things as well just cant recall what they are. I think it is because they have so much more activities that we didn't have when younger like extreme skating and biking. Yeah !!! when he gets to that stage. We have to slow him down sometimes but sure has pulled a few stunts that we don't know of.

#1992

i had a herniated gut area with 18in of intestine outside the stomach wall due to a failed appendix incision (appendix was soda can sized) green stick broke my collar bone at 7 watching arnold palmer golfing the fence me an 10 other kids were on collapsed lol he came over to help extract us from the debris

#1993

You don't need to be that specific, Terry with hundreds of thousandths of an inch.... and I have found it to be generally true that if you get that first measurement as close to center median point as you can, the rest will be dead on . Are you just installing them on a random throttle body and testing from there?

#1994

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

Hello Mark...I have them on their orginal Throttle body. I know they are picky on their placement so I have just left them on with the Throttle Body. Each one will only fail one test but they all fail different test. I am going to order a new one and see what that does for me.

I have been checking in on your thread. Hope all is well for your dad. Builds have slowed down alot lately and not just on Yotatech. I am trying to get things moving again on my end.

I have been checking in on your thread. Hope all is well for your dad. Builds have slowed down alot lately and not just on Yotatech. I am trying to get things moving again on my end.

#1995

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

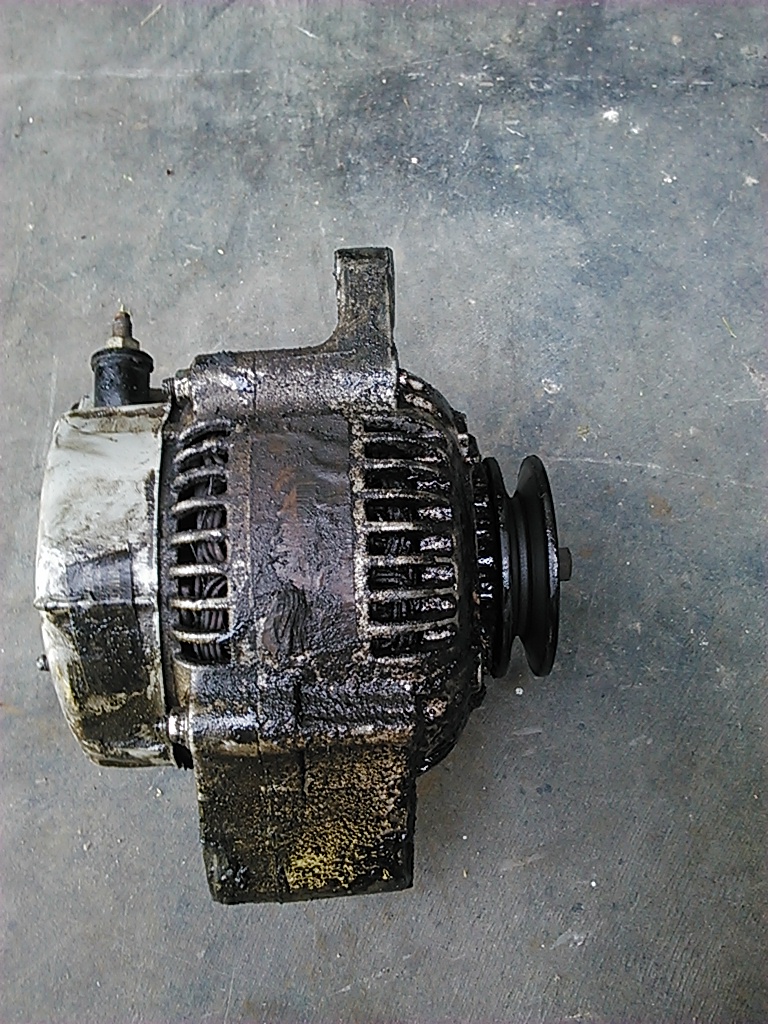

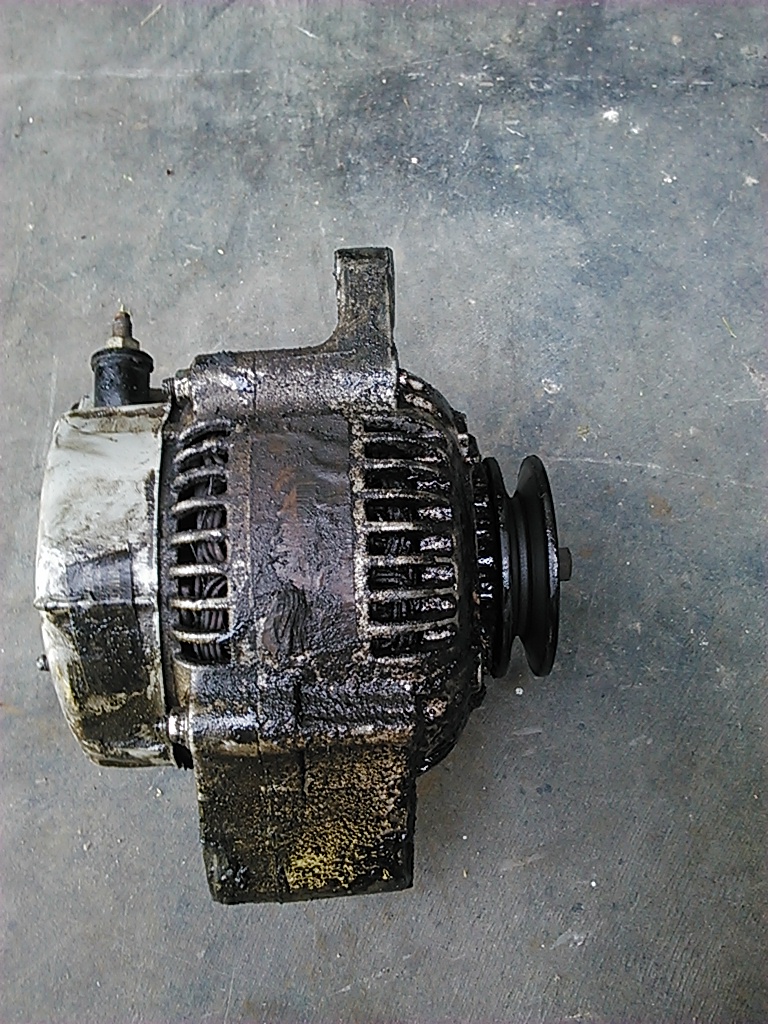

Today I took the pick up for a drive. So far so good. I have been having some issues with the alternator as sometimes the Brake and Alt light comes on and sometimes it doesnt. I am just going to order new brushes for it. I have had part store alternators and some were even Denso that were rebuilt in Mexico and had issues with them. I trust my work better then the rebuilts.

Anther issue is the fuel guage. It wont move off of Empty. I have another guage and plugged it in and moved the float thru it movements to see if the issue was float assembly or elsewhere. It worked great. So now I get to lift the bed back up to change that out.

How I do a quick test. Just connect it to the harness above the tire and move the float.

Anther issue is the fuel guage. It wont move off of Empty. I have another guage and plugged it in and moved the float thru it movements to see if the issue was float assembly or elsewhere. It worked great. So now I get to lift the bed back up to change that out.

How I do a quick test. Just connect it to the harness above the tire and move the float.

#1996

Thanks Cyberhorn, thanks Terry. I just pulled up the FSM and am working on setting up a table of the appropriate dimensions. I don't have a press myself, but some friends of mine have one at their shop i can use. I'd have liked to be fully underway by now but my 2 jobs slammed me over the weekend and yesterday i was in recovery mode. I'm going to have to do some nonchalant post padding before i can start a new thread on this, but i'll try and keep it relevant. May as well let it be known I am in over my head with this thing.

#1997

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

Hello ashmerlin.. I am eventully going to be setting up a table in my storage shed and will take a each piece and lay in the order that it came off. If you have a bad transmission, it would be an excellent piece to practice on. I have learned so much on old or broken parts. In alot of cases I have been able to combine two bad parts to make one good part.

As far as being in over your head, that is the best way to learn and is quite rewarding when you come out on the other side and you understand it so much better. Slow and steady gets it done. Some things I may just spend 30 minutes a day on when possible and it adds up really quick. Go thru any thread on Yotatech and one page usually isnt much, but several pages later it is a truck done to the way the owner wants it. You will get there.

As far as being in over your head, that is the best way to learn and is quite rewarding when you come out on the other side and you understand it so much better. Slow and steady gets it done. Some things I may just spend 30 minutes a day on when possible and it adds up really quick. Go thru any thread on Yotatech and one page usually isnt much, but several pages later it is a truck done to the way the owner wants it. You will get there.

#1998

Thread Starter

Joined: Aug 2008

Posts: 11,787

Likes: 25

From: Anderson Missouri

I got the alternator pulled off. I always have to remove the bottom radiator hose to get it out. I havent really gone thru the mechanics of this truck but the lower hose is needing replaced. I got the alternator brushes and the lower hose so will fix two problems at the same time.

After getting the alternator off, I noticed the Power Steering is leaking. I have a spare pump but will need to see if it is the pump or hose that is leaking. I dont mess around with Power Steering leaks. I had an 89 to catch fire as the fluid will drip right on to the alternator. Luckily I was able to get it out and all it did was blow the 80 amp fuse.

I will be taking this one apart and cleaning it and replacing the brushes. I will post pics later tonite. The orginal brushes are fairly long and they wear down quite a bit.

PS leak.

After getting the alternator off, I noticed the Power Steering is leaking. I have a spare pump but will need to see if it is the pump or hose that is leaking. I dont mess around with Power Steering leaks. I had an 89 to catch fire as the fluid will drip right on to the alternator. Luckily I was able to get it out and all it did was blow the 80 amp fuse.

I will be taking this one apart and cleaning it and replacing the brushes. I will post pics later tonite. The orginal brushes are fairly long and they wear down quite a bit.

PS leak.

#1999

i have tested 5 different throttle position sensors and using the fsm and 4crawlers information which is basically the same, none of them have come in with the same readings as what is mentioned in the test procedures. I am going to test mistys and my tps here in the next few days to see what the numbers on them. I cant see 5 all being bad as i know a couple did come off of running trucks. I am leaving a little leeway for the numbers so i am not getting that strict on the numbers.

I did go buy a new feeler gauge and the test says .0224 my gauge is .022, in my opinion the .0004 would be dealing with something like the thickness of a hair and shouldn't make a difference as it is so small. Do i need to find a feeler gauge that goes that small??? Where would i find one that small???

I did go buy a new feeler gauge and the test says .0224 my gauge is .022, in my opinion the .0004 would be dealing with something like the thickness of a hair and shouldn't make a difference as it is so small. Do i need to find a feeler gauge that goes that small??? Where would i find one that small???