RAD4Runner's 1986 4Runner dlx Build-up

#21

I have run into the starter problems you have mentioned. Wish I had your electrical knowledge. I know just enough to be dangerous, I just replaced a starter as I was having to smack it. I am suspecting it just needs the contacts replaced.

#22

Yes, it's possible that the contacts are bad. I have no experience with that, yet. Did you trade in your old starter? Would be interesting to see the contacts.

I don't want to remove my starter, yet, because:

- I can hear starter relay and feel it click but no crank.

- On the other hand, when I connect my starter solenoid control terminal directly to battery, it cranks.

NO rush because I already have a bypass setup (to connect my starter solenoid control terminal directly to battery). Will post this as soon as I get a chance.

#23

Hmm this is some very interesting info on the starter relay. I "freshened up" my starter contacts by sanding them down to remove the pitting and the groove worn by the plunger, and it eliminated like 99% of my start issues. But there is still that 1% of the time where I just get a click. Makes me wonder if the starter relay contacts or ignition contacts are worn as you noted. I'm subscribed, I wanna see how yours works out, you've got some good electrical skills.

#24

Troubleshooting Starting System - Divide & Conquer

Hmm this is some very interesting info on the starter relay. I "freshened up" my starter contacts by sanding them down to remove the pitting and the groove worn by the plunger, and it eliminated like 99% of my start issues. But there is still that 1% of the time where I just get a click. Makes me wonder if the starter relay contacts or ignition contacts are worn as you noted. I'm subscribed, I wanna see how yours works out, you've got some good electrical skills.

Fresh, clean contacts would surely help, but since you had it already taken apart, you could have saved time by replacing with new contacts. I believe 4Crawler's site talks about.

I proceeded to bypass ST1 contact by moving terminal 4 of starter relay to downstream (fused) terminal of the 40-Amp (AM1) Fusible link (schematic). This is similar to what the Painless Wiring Hot Shot relay mod accomplishes. (Sorry no time to post pics.). This will lower resistance from battery to starter solenoid and help extend the life of start contacts (ST1) on ignition switch.

How to narrow it down to the starter relay, knowing that COR clicks, clutch safety cancel switch and clutch position switch are good?

To thoroughly troubleshoot, one needs to be able to turn Ign switch & listen/feel the relay & solenoids. Problem is intermittent, and you need to be able to reach the start key and feel/listen to starter relay and/or starter solenoid click so When that happens and you do not have company use RAD4Runner's Special Service Tool

Standing at right side between engine compartment and front door, near location of starter relay, hook AHA tool over your key and start. Does your starter relay click? If it does not, possible causes:

- Coil is open/broken. (Pix & more details to follow...)

- Power and or ground is not getting to starter relay coil it from ST1 contacts of Ignition switch.

Start relay clicks but solenoid does not thunk (heavier clicking). Possible causes:

- Power from starter relay not getting to solenoid, or

- High resistance on relay contact, and/or start contact (ST1 on IGN switch) not allowing full voltage to solenoid. (Follow orange line on schematic above to see this circuit.)

- Starter relay contact does not close completely.

- Starter solenoid stuck/hard to actuate (smack it to test)

- Starter solenoid coil open

Test Starter Solenoid:

Without "starting" ignition key, connect this terminal of starter solenoid directly to battery. Solenoid should thunk and starter would turn over.

If so, wire from relay and or circuit upstream of it is defective.

If no thunk, possibly:

- Starter solenoid stuck/hard to actuate (smack it to test)

- Solenoid coil bad. Measure resistance.

Solenoid thunks but no turn-over:[*]Solenoid contacts bad.[*]Power not getting to starter[*]Ground not connected well to starter[*]Starter motor bad.

more to come...

Last edited by RAD4Runner; 09-21-2012 at 05:03 PM. Reason: Updated details

#25

#26

Verifying Starter Relay Function With Special Service Tool =D

When faced with intermittent "click only" starting issue, the click one hears from behind the glove compartment is that of the circuit opening relay - related but does not affect cranking system.

To verify that power is energizing starter relay (inside engine compartment), and/or relay is energizing solenoid one needs to hear/feel the relay and solenoid click. IF, and only IF, this issue occurs to me while no one is around to help by turning key while I'm standing by right side of engine compartment near the starter relay, here's how I do it.

To verify that power is energizing starter relay (inside engine compartment), and/or relay is energizing solenoid one needs to hear/feel the relay and solenoid click. IF, and only IF, this issue occurs to me while no one is around to help by turning key while I'm standing by right side of engine compartment near the starter relay, here's how I do it.

Last edited by RAD4Runner; 01-08-2013 at 12:00 PM.

#27

Cleaned My Starter Relay Tonight

UPDATE:

This is how you would clean your starter relay contacts.

However, The procedure below did not fix the "click-only no-start" problem. Problem recurred. I reviewed schematic of 1986 to 1988 22RE cranking system and found a design flaw. Repair for the flaw is explained here.

I have intermittent no-start (crank) problem. Starter solenoid works and supplies power to starter motor when control (coil) terminal is directly connected to battery +.

I have verified that control power is getting to starter relay using method in earlier post (here).

With starter relay energizing, but starter solenoid not energizing, I suspect badly pitted /corroded starter relay contacts AND/OR ignition switch ST1 contacts causing high resistances and hence, excessive voltage drops.

To eliminate resistance of ignition switch ST1 contacts, I moved terminal 4 of starter relay directly to fused side of 40A fuse (see schematic here)

I was left with potentially bad starter relay contacts. I took starter relay part. Pic below shows starter relay with contacts open.

It is difficult to tell condition of contacts without a microscope and I could not find my 2000 grit lapping film, so I just ran 400 grit sandpaper a couple of times between contacts and blew clean with air spray can. That should remove any pitting/corrosion.

I'll monitor and see if I still have any starting issue.

How does the relay work?

One side of contact is connected to +12Volt (ideally directly from fused line directly off the battery and NOT through ignition switch as in schematic). Other side of contact is connected to control (coil) terminal of starter solenoid here.

One side of relay coil is connected to ground through clutch safety switch (when clutch is pushed down) or clutch safety cancel switch (if activated).

Other side of coil gets +12Volts from start contacts (ST1) of ignition switch.

Coil creates electromagnetic force and pulls armature toward it, closing contacts and causing current to flow to starter solenoid (piggybacked on starter motor). Here's a video of starter relay energizing (housing removed).

[YOUTUBE]

[/YOUTUBE]

UPDATE:

The procedure above did not fix the "click-only no-start" problem. Problem recurred. I reviewed schematic of 1986 to 1988 22RE cranking system and found a design flaw. Repair for the flaw is explained here.

This is how you would clean your starter relay contacts.

However, The procedure below did not fix the "click-only no-start" problem. Problem recurred. I reviewed schematic of 1986 to 1988 22RE cranking system and found a design flaw. Repair for the flaw is explained here.

I have intermittent no-start (crank) problem. Starter solenoid works and supplies power to starter motor when control (coil) terminal is directly connected to battery +.

I have verified that control power is getting to starter relay using method in earlier post (here).

With starter relay energizing, but starter solenoid not energizing, I suspect badly pitted /corroded starter relay contacts AND/OR ignition switch ST1 contacts causing high resistances and hence, excessive voltage drops.

To eliminate resistance of ignition switch ST1 contacts, I moved terminal 4 of starter relay directly to fused side of 40A fuse (see schematic here)

I was left with potentially bad starter relay contacts. I took starter relay part. Pic below shows starter relay with contacts open.

It is difficult to tell condition of contacts without a microscope and I could not find my 2000 grit lapping film, so I just ran 400 grit sandpaper a couple of times between contacts and blew clean with air spray can. That should remove any pitting/corrosion.

I'll monitor and see if I still have any starting issue.

How does the relay work?

One side of contact is connected to +12Volt (ideally directly from fused line directly off the battery and NOT through ignition switch as in schematic). Other side of contact is connected to control (coil) terminal of starter solenoid here.

One side of relay coil is connected to ground through clutch safety switch (when clutch is pushed down) or clutch safety cancel switch (if activated).

Other side of coil gets +12Volts from start contacts (ST1) of ignition switch.

Coil creates electromagnetic force and pulls armature toward it, closing contacts and causing current to flow to starter solenoid (piggybacked on starter motor). Here's a video of starter relay energizing (housing removed).

[YOUTUBE]

UPDATE:

The procedure above did not fix the "click-only no-start" problem. Problem recurred. I reviewed schematic of 1986 to 1988 22RE cranking system and found a design flaw. Repair for the flaw is explained here.

Last edited by Terrys87; 08-14-2015 at 07:45 PM.

#28

Deck Light Mod

Decklight is puny and gets blocked often. I simply

Results:

A plus to mounting where I did is that the rollbar blocks glare of the LED light when driver looks behind or through rear-view mirror.

I could have mounted on roll bar but I often tie something to that and ropes would damage wiring and LED array.

BTW, that's the first of two shoulder seatbelt I'm installing from second-gen 4Runner.

Note that taillights have to be on in order to turn on deck light. Next phase is to rewire so decklight circuit takes power from domelight circuit.

- Mounted/stuck LED array above the wiper mechanism housing.

(I happened to have flexible array, or else I would have installed an LED fixture on wiper housing instead.) - Ran wire into wiper compartment, and ran it down the rear pillar to left rear corner to join wiring harness

- Then tapped off power to LED array from the back of the existing decklight fixture.

Results:

A plus to mounting where I did is that the rollbar blocks glare of the LED light when driver looks behind or through rear-view mirror.

I could have mounted on roll bar but I often tie something to that and ropes would damage wiring and LED array.

BTW, that's the first of two shoulder seatbelt I'm installing from second-gen 4Runner.

Note that taillights have to be on in order to turn on deck light. Next phase is to rewire so decklight circuit takes power from domelight circuit.

Last edited by RAD4Runner; 10-02-2013 at 10:22 AM.

#32

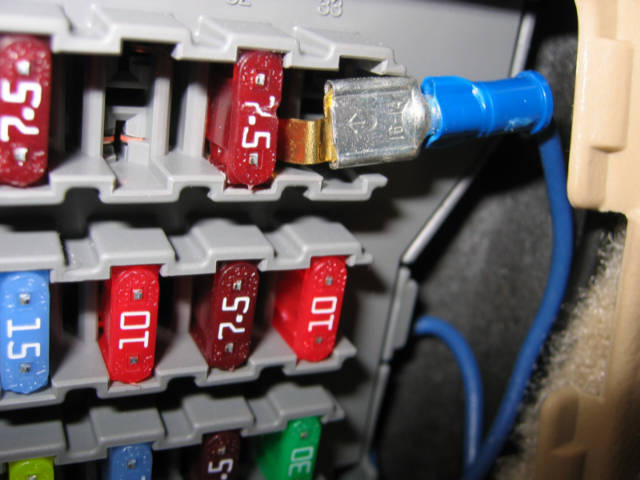

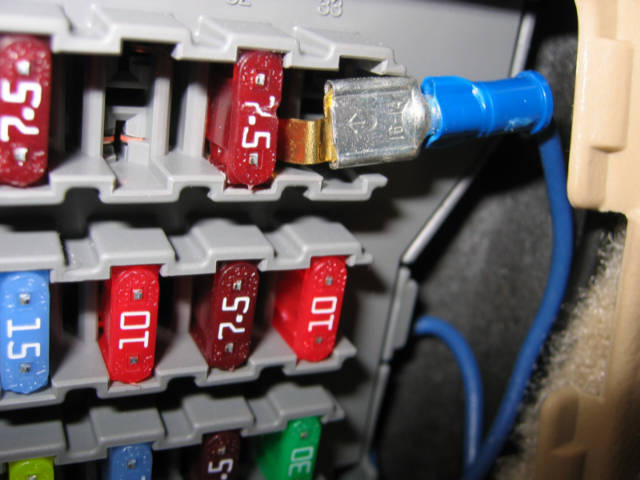

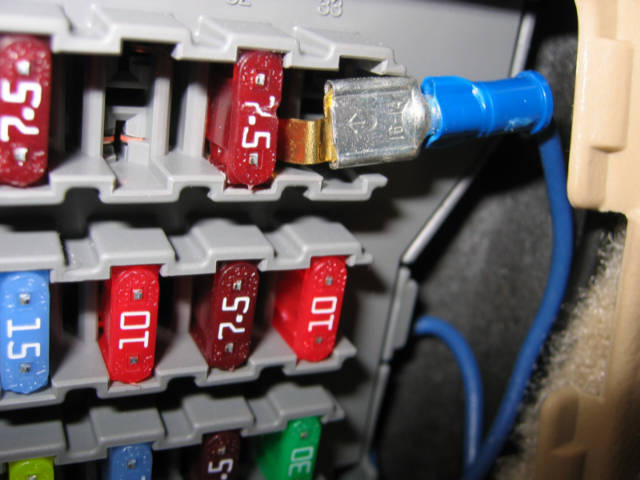

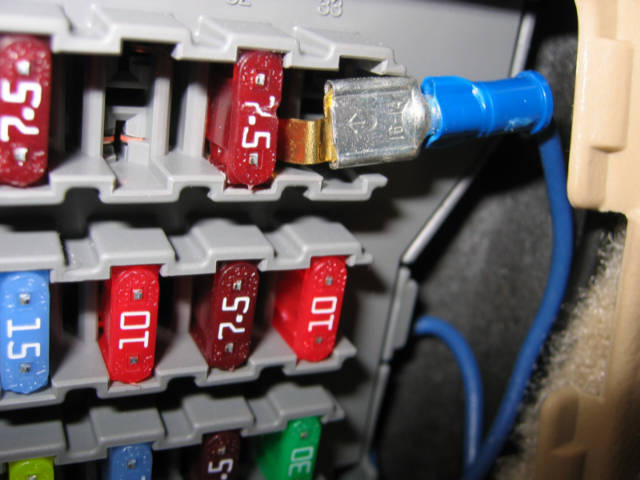

Improved connection to fuse panel

For a better, easier power connection:

Try this:

http://www.autozone.com/autozone/acc...fier=6427_0_0_

or this:

http://www.radioshack.com/search/ind...=fuse+tap&sr=1

To look like this (not a Toyota):

This is a positive, reliable connection. It is easily reversible (if you change your mind). If you put it on the correct side of the fuse (duh!), the new circuit is also protected by the fuse.

What about soldering to the back of the panel? Soldering usually makes a good electrical connection, but does not make an adequate mechanical connection. Unless you crimp it (somehow) before soldering, vibration will quickly crack the solder and you'll have a hard-to-find intermittent open.

The crimp connectors used by all auto manufacturers are the way to go, but I have found no source for them (the hardware-store "crushable" aluminum connectors are a pale imitation, but certainly better than soldering). (Note that the connector in the above picture was crimped with a "real" crimper that crushed it to the correct barrel shape, not the $7.95 combo crimper sold in hardware stores.)

Try this:

http://www.autozone.com/autozone/acc...fier=6427_0_0_

or this:

http://www.radioshack.com/search/ind...=fuse+tap&sr=1

To look like this (not a Toyota):

This is a positive, reliable connection. It is easily reversible (if you change your mind). If you put it on the correct side of the fuse (duh!), the new circuit is also protected by the fuse.

What about soldering to the back of the panel? Soldering usually makes a good electrical connection, but does not make an adequate mechanical connection. Unless you crimp it (somehow) before soldering, vibration will quickly crack the solder and you'll have a hard-to-find intermittent open.

The crimp connectors used by all auto manufacturers are the way to go, but I have found no source for them (the hardware-store "crushable" aluminum connectors are a pale imitation, but certainly better than soldering). (Note that the connector in the above picture was crimped with a "real" crimper that crushed it to the correct barrel shape, not the $7.95 combo crimper sold in hardware stores.)

#33

For a better, easier power connection:

Try this:

http://www.autozone.com/autozone/acc...fier=6427_0_0_

or this:

http://www.radioshack.com/search/ind...=fuse+tap&sr=1

To look like this (not a Toyota):

This is a positive, reliable connection. It is easily reversible (if you change your mind). If you put it on the correct side of the fuse (duh!), the new circuit is also protected by the fuse.

What about soldering to the back of the panel? Soldering usually makes a good electrical connection, but does not make an adequate mechanical connection. Unless you crimp it (somehow) before soldering, vibration will quickly crack the solder and you'll have a hard-to-find intermittent open.

The crimp connectors used by all auto manufacturers are the way to go, but I have found no source for them (the hardware-store "crushable" aluminum connectors are a pale imitation, but certainly better than soldering). (Note that the connector in the above picture was crimped with a "real" crimper that crushed it to the correct barrel shape, not the $7.95 combo crimper sold in hardware stores.)

Try this:

http://www.autozone.com/autozone/acc...fier=6427_0_0_

or this:

http://www.radioshack.com/search/ind...=fuse+tap&sr=1

To look like this (not a Toyota):

This is a positive, reliable connection. It is easily reversible (if you change your mind). If you put it on the correct side of the fuse (duh!), the new circuit is also protected by the fuse.

What about soldering to the back of the panel? Soldering usually makes a good electrical connection, but does not make an adequate mechanical connection. Unless you crimp it (somehow) before soldering, vibration will quickly crack the solder and you'll have a hard-to-find intermittent open.

The crimp connectors used by all auto manufacturers are the way to go, but I have found no source for them (the hardware-store "crushable" aluminum connectors are a pale imitation, but certainly better than soldering). (Note that the connector in the above picture was crimped with a "real" crimper that crushed it to the correct barrel shape, not the $7.95 combo crimper sold in hardware stores.)

Before you start tearing up your wiring, consider this:

https://www.yotatech.com/forums/f199...l#post51963941

https://www.yotatech.com/forums/f199...l#post51963941

Oh no; I'm totally against tearing up wiring; I feel bad for fellow members whose 4Runners' PO's did that, that's why my posts stress lean , clean, and documented

. I tapped off like that because I did not know how to remove fuse block from bulkhead then and did not get responses to my queries, but wanted right away (first mod as soon as I got the Runner) to prevent unintentional dead battery. Last night, Terry87 showed me how (above), so this weekend I will cleanly re-wire and solder directly to fuse block terminal in the back. Oh yeah, agree with crimping, so I always crimp/wrap wire (mechanical integrity) and solder (electrical integrity and corrosion-resistance).

. I tapped off like that because I did not know how to remove fuse block from bulkhead then and did not get responses to my queries, but wanted right away (first mod as soon as I got the Runner) to prevent unintentional dead battery. Last night, Terry87 showed me how (above), so this weekend I will cleanly re-wire and solder directly to fuse block terminal in the back. Oh yeah, agree with crimping, so I always crimp/wrap wire (mechanical integrity) and solder (electrical integrity and corrosion-resistance).

Last edited by RAD4Runner; 08-24-2012 at 09:45 AM.

#34

I liked your one person ability to testing the relay. I do 99% of the work by myself and have had to come up with some things that would be nice to have someones help. Actually I will be testing the starter relay on the 88 pickup I am working on. Will need to figure out how to get the cover off. Most of the time cleaning the contacts makes a big difference.

I must of missed your queries you were talking about as I usually dont get on the homepage to often, but will try scanning the 84-95 section and see if there is anything someone might have been skipped over on that I can help. Hit me up on one of my build threads and I will catch it quicker. Your mods turn out great.

I must of missed your queries you were talking about as I usually dont get on the homepage to often, but will try scanning the 84-95 section and see if there is anything someone might have been skipped over on that I can help. Hit me up on one of my build threads and I will catch it quicker. Your mods turn out great.

#35

Sorry, lost my 10-mm socket so I couldn't take off relay for photo op. However, it is easy to open the starter relay. Just straighten out the 4 (?) metal tabs of can that hold the plastic part of the housing, then carefully pry plastic part out of the can (i.e., with big jeweler's screwdriver). The rubber gasket creates a tight fit but that will give way. Don't worry, it's not hermetically sealed (air tight), so you're not breaking anything. Just be careful with the very fine magnet wire.

Takes a microscope under good lighting to inspect. Replace if it's beyond repair/badly pitted. However, I doubt that because it is meant to handle starter solenoid relay current. I would suspect pitted ST1 contacts on IGN sw first.

I would not trust replacing with one from another first-gen (just as old), unless inspected and OEM is too expensive, so if I could find a later gen's that's compatible I'd use that. I actually measured coil current on solenoid (that passes through the starter relay) at 12Amps. I'd look for relay rated for at least 30Amp.

...I must of missed your queries you were talking about...

#38

BTW, about halfway done with my Peel & Seal sound dampening project. Sounds promising. No tar smell like many are saying, and we have 3-digit temps in SD.

#40