Daenerysdad '93 DIY Blazeland long travel

#61

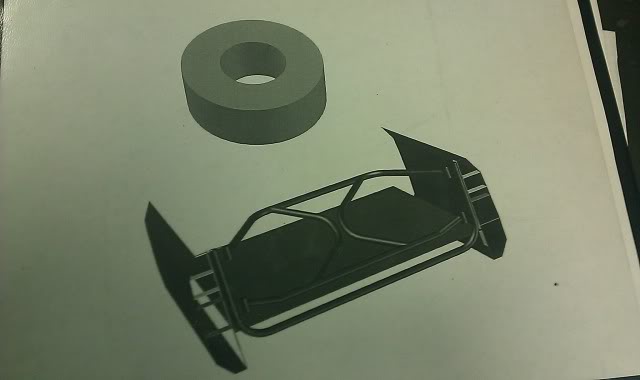

started plugging on my spare tire swing out tailgate..... thing. So whipped up this thing in autocad and now I'm wasting metal hoping it all fits together.

Whipped up some (two) 3/16" plates that bolt up where all the factory goodies are supposed to go... Wheeeee!

Big "U" thing gets glued to the 3/16" plate plates things then bolted up where all the factory goodies are supposed to go.

And without anything but MAGNETS and some good old fashioned gravity holding it to the table this is what it will look like, but with other stuff on it. And it'll be welded too.... maybe. And on the truck.

#65

Over the weekend started in on inner fender wells. Fiberglass is cool and all, but really it sucks. Used some of the wife's fleece that I found in a drawer in her craft room...  probably hear about that later...

probably hear about that later...

Then at school, threw up the tire on the main cross bars just for giggles to see where everything looked like it'd lay.

probably hear about that later...

probably hear about that later...

Then at school, threw up the tire on the main cross bars just for giggles to see where everything looked like it'd lay.

#70

Ahhh, not really. Hammered off the wheels...

Clawed off some brake lines n such...

Pounded the diff apart...

And knocked in a lock rite...

Running with the local off-road club this Sunday to test it out. So far, road manners are a little different. Under steer when giving it some go-pedal thru a turn. Hop/surge when idling thru a corner. Barely audible tick when you take the corner with slight throttle.

Clawed off some brake lines n such...

Pounded the diff apart...

And knocked in a lock rite...

Running with the local off-road club this Sunday to test it out. So far, road manners are a little different. Under steer when giving it some go-pedal thru a turn. Hop/surge when idling thru a corner. Barely audible tick when you take the corner with slight throttle.

#72

#76

DSM, I made a transaction with Teuf, he had a set of (IIRC) 26mm torsion bars. Have had those on for quite a while now, and honestly, I'm not running enough weight to justify that much thickness. At max flex, (i.e. front driver compressed, front pass. at full droop, then rear driver full droop, rear pass full stuff) the front driver would still have about ~4 to 6" of room to compress... Just a little too stiff, not allowing for full range of up motion. I'm beginning to think coil overs are my next step to getting the range I'm capable of. $$ is the problem  another thing is today while roading with my off road group, I ground up the bearing in a CV on the diff side. Had to pull it out on trail to continue, which is no big deal, but it broke while doing some not that crazy $hiz... which is also disconcerting when I'm only running 32" all terrains right now. If I'm going to blowing up cv axles because of my angles, I'm either going to have to fab up the supra diff and custom cv's or do the thing I don't want to but probably should have and SAS the damn thing.

another thing is today while roading with my off road group, I ground up the bearing in a CV on the diff side. Had to pull it out on trail to continue, which is no big deal, but it broke while doing some not that crazy $hiz... which is also disconcerting when I'm only running 32" all terrains right now. If I'm going to blowing up cv axles because of my angles, I'm either going to have to fab up the supra diff and custom cv's or do the thing I don't want to but probably should have and SAS the damn thing.

another thing is today while roading with my off road group, I ground up the bearing in a CV on the diff side. Had to pull it out on trail to continue, which is no big deal, but it broke while doing some not that crazy $hiz... which is also disconcerting when I'm only running 32" all terrains right now. If I'm going to blowing up cv axles because of my angles, I'm either going to have to fab up the supra diff and custom cv's or do the thing I don't want to but probably should have and SAS the damn thing.

another thing is today while roading with my off road group, I ground up the bearing in a CV on the diff side. Had to pull it out on trail to continue, which is no big deal, but it broke while doing some not that crazy $hiz... which is also disconcerting when I'm only running 32" all terrains right now. If I'm going to blowing up cv axles because of my angles, I'm either going to have to fab up the supra diff and custom cv's or do the thing I don't want to but probably should have and SAS the damn thing.

#77

Thanks for sharing your experiences with what sounds like the Downey torsion bars. If they were in fact the Downey's (Teuf?) I think you just saved me some coin. A guy local to me was looking to unload a set and I was considering picking them up for safe keeping in the event I decide to do a LT front end on my '93 4Runner. Sounds like even with the additional width they're still too much. If they're that stiff with that extra width you've got I can't imagine what they'd be like on a stock width truck.. Ehh!

Sucks about your CV.. Keep us posted!!

Sucks about your CV.. Keep us posted!!

#78

Eric,

Sounds like it could be Downey TB? Downey usually paints identification markings in white or yellow lettering. I've seen the words "Downey" and "front" or "rear" or "left" or "right" painted on the TB. On my heavy metal Fordota the 26mm were great. On the lighter 4 Runner they worked decent but with a lot less pre-load. It also depends on what your doing with your ride. If your pre-running and jumping where its taking a pounding with speed a higher spring rate TB is better where a slow speed crawler needs a lighter spring rate. This will apply towards a coil spring set up as well. I have found that just about every spring combination I have tried (TB, Coil, even leaf) the rear will show more flex. I am planning on trying rear sway bars to balance this condition.

As for CV axle strength the original factory T-100s seem to be the strongest. Aftermarket ones are less reliable, you may get what you pay for, $65 an axle with a lifetime warranty means your likely going to want a spare.

My advice is to unload the TB and cycle the suspension to find what is binding in the CV. Then adjust your limits to prevent the binding. I have found when the CVs bind on themselves that is often the reason. You will have to interpolate the amount of compression within the bump / droop stops with the type of forces you subject them to. Maximizing every inch of wheel travel may mean binding something and breaking. Being more conservative may mean less wheel travel but you will gain strength and longevity.

If you can investigate what failed in your CV and why did it fail. Consider things like was it at full droop or stuff, wheels turned all the way left or right, was the front end bouncing and subject to a shock load, etc. A smooth, evenly applied torque load with the CVs at a minimal angle will probably be greater than what your rig can produce. But when one compounds the gear reduction, increase the horsepower, apply a shock load, bind the CV on itself, wedges the wheel on an immovable object, use the momentum force and weight of the vehicle and rolls into a bind then something is going to break.

If your able to identify how and why your CV failed you can adjust your driving technique to avoid future failure. Keep in mind the physical dimensions and strength characteristics of a xx spline axle along with the angle limits of the CV joints can only support a given amount. You could SAS your rig and use a xx spline axle with all the best materials and components but that too will eventually fail in the right condition. Nothing is indestructible. Part of being a good driver is knowing these limits, picking an appropriate line, and using a proper technique. Hope that helps!

Sounds like it could be Downey TB? Downey usually paints identification markings in white or yellow lettering. I've seen the words "Downey" and "front" or "rear" or "left" or "right" painted on the TB. On my heavy metal Fordota the 26mm were great. On the lighter 4 Runner they worked decent but with a lot less pre-load. It also depends on what your doing with your ride. If your pre-running and jumping where its taking a pounding with speed a higher spring rate TB is better where a slow speed crawler needs a lighter spring rate. This will apply towards a coil spring set up as well. I have found that just about every spring combination I have tried (TB, Coil, even leaf) the rear will show more flex. I am planning on trying rear sway bars to balance this condition.

As for CV axle strength the original factory T-100s seem to be the strongest. Aftermarket ones are less reliable, you may get what you pay for, $65 an axle with a lifetime warranty means your likely going to want a spare.

My advice is to unload the TB and cycle the suspension to find what is binding in the CV. Then adjust your limits to prevent the binding. I have found when the CVs bind on themselves that is often the reason. You will have to interpolate the amount of compression within the bump / droop stops with the type of forces you subject them to. Maximizing every inch of wheel travel may mean binding something and breaking. Being more conservative may mean less wheel travel but you will gain strength and longevity.

If you can investigate what failed in your CV and why did it fail. Consider things like was it at full droop or stuff, wheels turned all the way left or right, was the front end bouncing and subject to a shock load, etc. A smooth, evenly applied torque load with the CVs at a minimal angle will probably be greater than what your rig can produce. But when one compounds the gear reduction, increase the horsepower, apply a shock load, bind the CV on itself, wedges the wheel on an immovable object, use the momentum force and weight of the vehicle and rolls into a bind then something is going to break.

If your able to identify how and why your CV failed you can adjust your driving technique to avoid future failure. Keep in mind the physical dimensions and strength characteristics of a xx spline axle along with the angle limits of the CV joints can only support a given amount. You could SAS your rig and use a xx spline axle with all the best materials and components but that too will eventually fail in the right condition. Nothing is indestructible. Part of being a good driver is knowing these limits, picking an appropriate line, and using a proper technique. Hope that helps!

#80

So what is binding? Limiting away 2" of droop seems really extreme? The thickness between a factory "bump" stop and a factory "droop" stop is only fractions of an inch. I could see that translating to a bit more when considering the length of the lever arm with respects to the location of the fulcrum between the pivot and the opposite end, but I wouldn't think 2"

I suspect there is something going wrong in the CV axle assembly if its binding at droop that early. It may seem the opposite but when the suspension is at droop the CV axle needs to shorten in length. The longest it will measure is when the CV is parallel to the ground. When the change in length occurs it takes place in the inner barrel where the tripod rolls in and out. This is often called plunge. Think of a toilet plunger.

Anyway, I have come across some aftermarket CVs that cap off the end of the barrel with a flat lid. It shouldn't be a flat lid, it should look like what is show in the photo below.

The stamp shaped cap will allow the tripod to push inward further. Also sometimes the caps with the relief stamps are not indexed correctly to match the location of the tripod. If that is the case being out of alignment will limit the plunge.

Check the end cap design on your CV. If its the shaped cap then make sure its indexed properly over the tripod.

I suspect there is something going wrong in the CV axle assembly if its binding at droop that early. It may seem the opposite but when the suspension is at droop the CV axle needs to shorten in length. The longest it will measure is when the CV is parallel to the ground. When the change in length occurs it takes place in the inner barrel where the tripod rolls in and out. This is often called plunge. Think of a toilet plunger.

Anyway, I have come across some aftermarket CVs that cap off the end of the barrel with a flat lid. It shouldn't be a flat lid, it should look like what is show in the photo below.

The stamp shaped cap will allow the tripod to push inward further. Also sometimes the caps with the relief stamps are not indexed correctly to match the location of the tripod. If that is the case being out of alignment will limit the plunge.

Check the end cap design on your CV. If its the shaped cap then make sure its indexed properly over the tripod.

You have now inspired me to invest in a pipe bender and start getting creative.

You have now inspired me to invest in a pipe bender and start getting creative.