1988 Toyota Unimog extra cab.

#41

#42

Thanks everyone for the kind words.

I will have some good portal pics coming this weekend. Got the brake lines fixed and seems to run good.. Well except for the loud grinding noise when I catch a little speed. Drove it about 5 miles then stopped to feel the drive train. All is cool except for the pinions. Closer to the flange the hotter. So I'm guessing that is where my noise is coming from. Going to start with the rear axle and tear into it. Pretty much have to take the whole thing apart just to get to the bearing. Should be some pretty interesting and rarely documented tech to come.

I will have some good portal pics coming this weekend. Got the brake lines fixed and seems to run good.. Well except for the loud grinding noise when I catch a little speed. Drove it about 5 miles then stopped to feel the drive train. All is cool except for the pinions. Closer to the flange the hotter. So I'm guessing that is where my noise is coming from. Going to start with the rear axle and tear into it. Pretty much have to take the whole thing apart just to get to the bearing. Should be some pretty interesting and rarely documented tech to come.

#44

So I've been hearing a real loud noise at speed. Sounds like grinding or some sort of metal on metal. So i drove around a bit. Then felt around the drive train, the only thing that was hot to the touch was both pinions. So i tore the whole axle apart to see IF i could find anything wrong. Didn't really find too much. A little metal shavings here and there but nothing that I think would be making the noise.

This nut gave me the business! Almost stripped! The welds on the horseshoe brace got in the way. Had to customize my wrench.

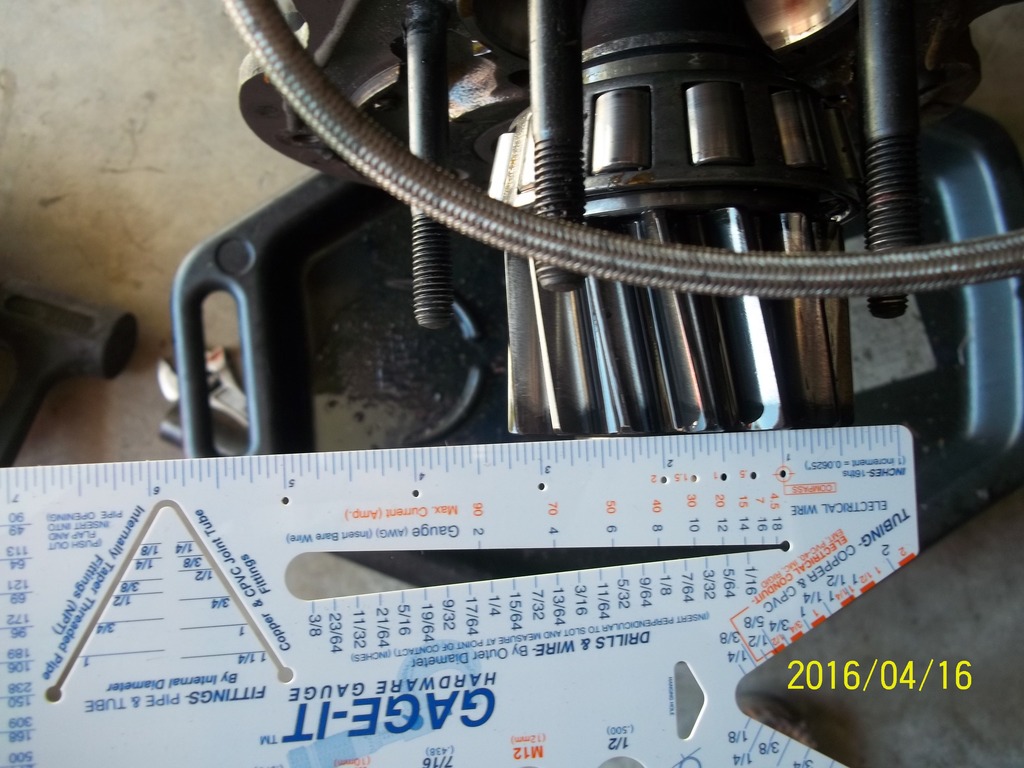

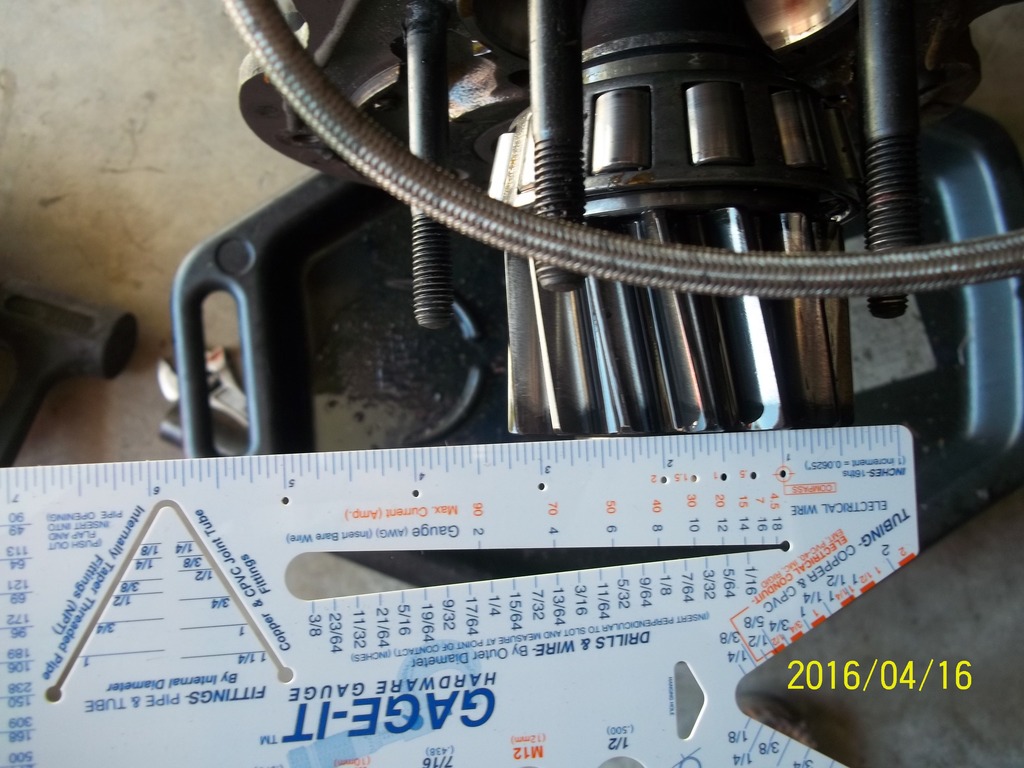

Everything was bigger than i thought. So i decided to measure it all for those who haven't seen it.

This nut gave me the business! Almost stripped! The welds on the horseshoe brace got in the way. Had to customize my wrench.

Everything was bigger than i thought. So i decided to measure it all for those who haven't seen it.

#45

#46

This was another possible problem. It was all milky.

Again everything looked good! everything spins nicely. pinion bearing seems to be just fine.

This doesn't look good but it still can't be my horrible noise.

Oh i pulled this our of the bottom torq tube bolt hole, metal bits. But i figure its just remanence from old screws that used to be in there? Im not sure tho.

Any help is really appreciated. Does anything look wrong with these parts?

All parts spin nicely. Seems like a healthy axle??

#47

I think the grind marks are your noise, the question is why are the axle components making contact.

Bearing play, wallowed out housing or bearing race?

Looks like it would be hard to assemble and pull side to side by hand to pinpoint.

Does the outer housing have dowel pins to locate and keep it from moving?

Bearing play, wallowed out housing or bearing race?

Looks like it would be hard to assemble and pull side to side by hand to pinpoint.

Does the outer housing have dowel pins to locate and keep it from moving?

#48

I think the grind marks are your noise, the question is why are the axle components making contact.

Bearing play, wallowed out housing or bearing race?

Looks like it would be hard to assemble and pull side to side by hand to pinpoint.

Does the outer housing have dowel pins to locate and keep it from moving?

Bearing play, wallowed out housing or bearing race?

Looks like it would be hard to assemble and pull side to side by hand to pinpoint.

Does the outer housing have dowel pins to locate and keep it from moving?

Honestly i don't think the axle is my problem after taking it all apart. The pinion was the only hot spot and it seems to be fine. No real metal shavings either like you would expect from grinding noise. Everything spins nice and looks good. Going to move to the drive train now.

the only dowel pins are in the third member, two of them.

The portal boxes just have a crap ton of bolts.

#49

So i found my problem. Looks like the brakes are closer then i thought. The back end of the bolts were rubbing against the caliper. I didn't even notice until i put the whole axle BACK TOGETHER!!:mad3: But at least i noticed it. I tightened the 24 bolts up and sure enough they were loose on the end that was scraping. Still don't feel comfortable with THAT little clearance so ill probably get wheel spacers. The box braces/caliper mounts were welded on all ˟˟˟˟ ˟˟˟˟ery like!!! There are gaps from box to brace and they are crooked as hell so the pads are wearing awkwardly, ill have to get some misalignment washers. So I'm sure if they were set up right it would not be rubbing on the bolts.

#50

My high steer arm was rubbing my cv while the wheel is turned. Grown down the cv a bit but I'm sure its fine. What is NOT find is the seal. i think messed the top inside seal. I don't know how to take apart the cv. Im not sure how to get to it. The axle won't slide out due to the cv. Ill have to do some research on some of the unimog forums to figure it out.

Here is the grind.

Here is the culprit.

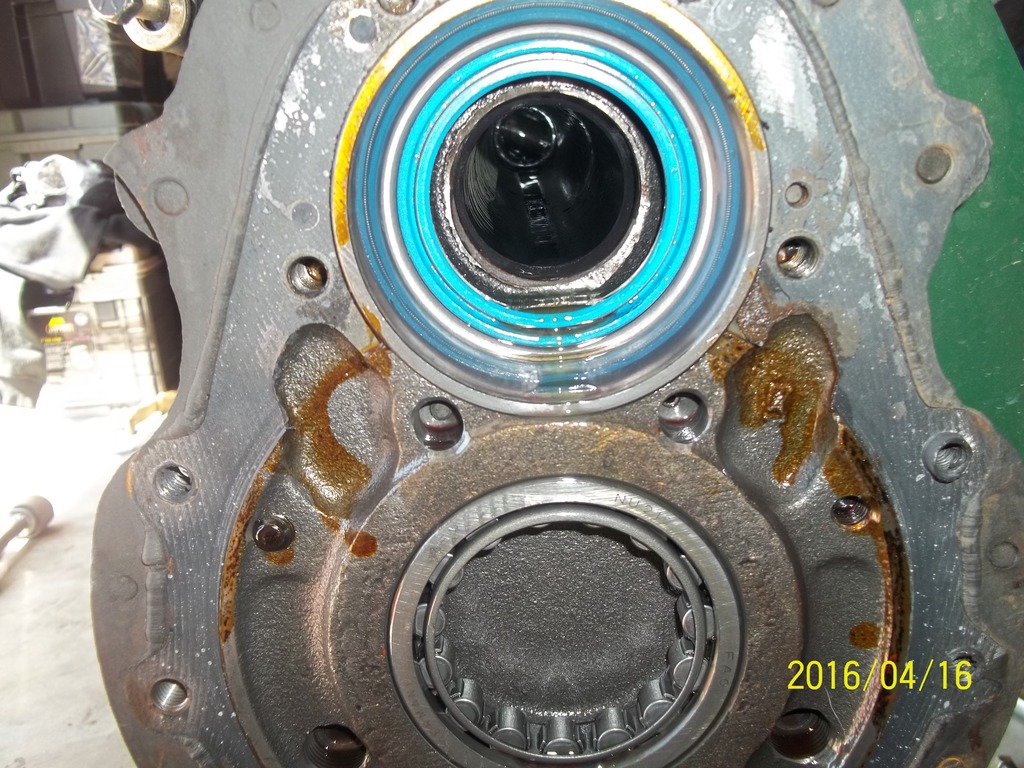

This seal in here is where it is leaking. I have the seal. Just confused on how to get to it.

Here is the grind.

Here is the culprit.

This seal in here is where it is leaking. I have the seal. Just confused on how to get to it.

#51

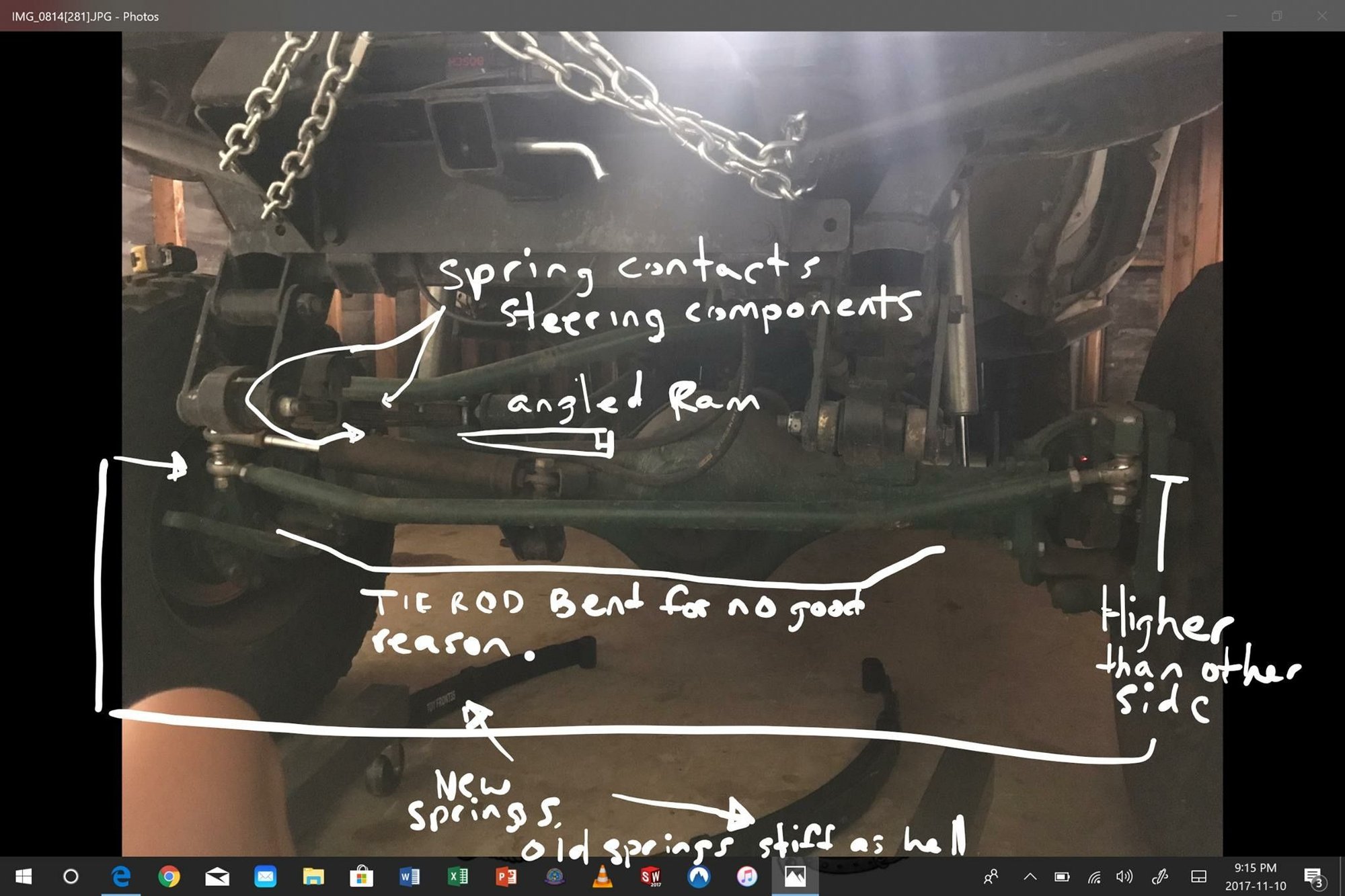

So the hack job suspension set up had me all over the road. In front i was resting on the overload springs so every little bump had me all over the road. The tires were pointed outboard and the caster was way off so i wasn't getting the full benefit of the portals because they were canted so much. I didn't get pictures of it but its fixed now. Also the traction bars were made with no way to adjust so at full rest the traction bar was forced into place twisting the axle and binding the suspension by putting a small curve in the leaf springs. I haven't fixed the front yet, it wasn't as bad as the rear. But i did fix the rear.

This is the front after i took the overload springs out.

This is the rear. I unbolted the traction bar and let the suspension settle without it and the bolts were about an inch off. So i chopped the bracket and started making another.

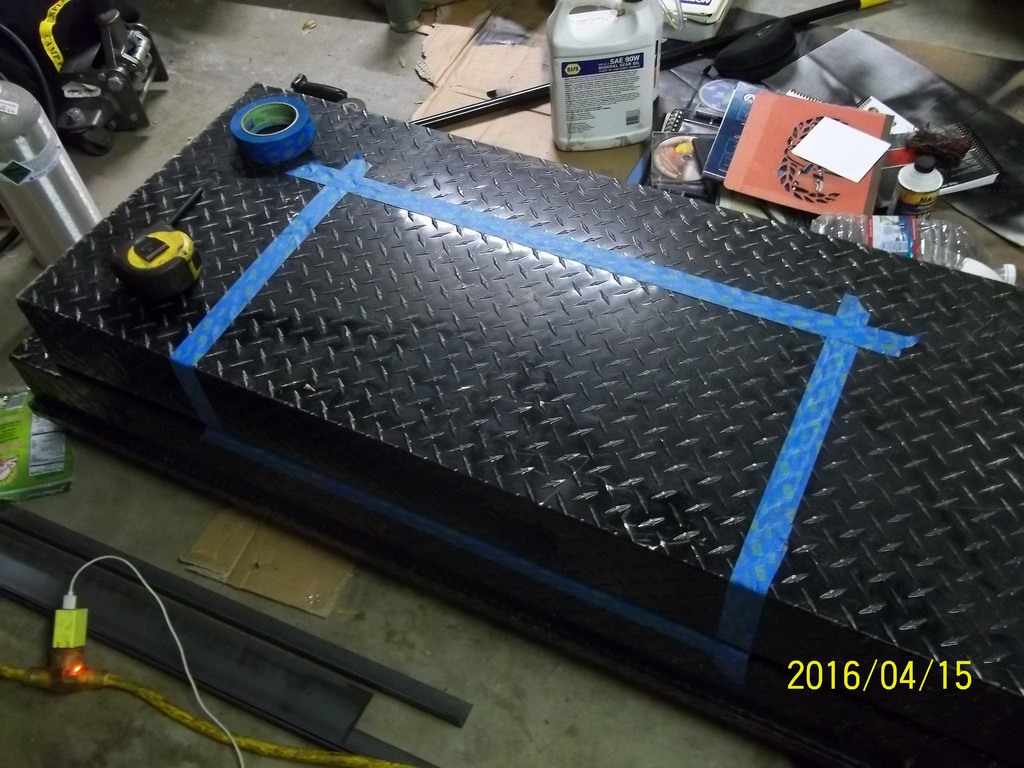

My mockup cardboard

Not bad for just a grinder and a cutter wheel.

This is the front after i took the overload springs out.

This is the rear. I unbolted the traction bar and let the suspension settle without it and the bolts were about an inch off. So i chopped the bracket and started making another.

My mockup cardboard

Not bad for just a grinder and a cutter wheel.

#54

Yeah me too!!

Thanks man. So I bought the axles rebuilt for 1800$ on eBay. 2100 with shipping. damn good deal if you ask me! I spent a lot on the disc break and 8 lug conversion. If i were to do it again i would not have done the disc breaks. So if i didn't do the disc brakes the only added cost would have been the pinion adapters. Those were around 650$. Not bad for geared and locked axles.

Thanks man. So I bought the axles rebuilt for 1800$ on eBay. 2100 with shipping. damn good deal if you ask me! I spent a lot on the disc break and 8 lug conversion. If i were to do it again i would not have done the disc breaks. So if i didn't do the disc brakes the only added cost would have been the pinion adapters. Those were around 650$. Not bad for geared and locked axles.

#55

maiden voyage

First run. Still a lot of kink to work out but she did pretty good.

Got to get a little more flex out of the rear. My shock location is limiting me. I need to relocate the shocks and put limit straps

I didn't get a pick but flexed up on the driver has my pitman arm locked up. Ill have to figure something out.

Got to get a little more flex out of the rear. My shock location is limiting me. I need to relocate the shocks and put limit straps

I didn't get a pick but flexed up on the driver has my pitman arm locked up. Ill have to figure something out.

#59

Update.

After having the work done by scar Offroad. I had many many issues with the suspension and performance overall. Slowly but surly I replaced the entire front suspension myself with a coiled radius arm suspension. Also reworked the rear suspension to perform better.

haha glad you found the problem

haha glad you found the problem