Elvota's 3.4 swap

#161

From that relay link I posted earlier,

Note:

Earlier I said that you energize the relay by applying positive voltage to either 85 OR 86 and grounding the remaining terminal. The only thing that changes when using the quenching diode is the fact that the positive terminal and the striped end of the diode must be together. If the positive control lead is connected to the diode's anode (unstriped end of diode). There will effectively be a short circuit to ground possibly causing damage to the control circuit (if the control circuit is not properly fused). A 1 amp fuse will carry more than enough current to energize the relay's coil.

Earlier I said that you energize the relay by applying positive voltage to either 85 OR 86 and grounding the remaining terminal. The only thing that changes when using the quenching diode is the fact that the positive terminal and the striped end of the diode must be together. If the positive control lead is connected to the diode's anode (unstriped end of diode). There will effectively be a short circuit to ground possibly causing damage to the control circuit (if the control circuit is not properly fused). A 1 amp fuse will carry more than enough current to energize the relay's coil.

#162

I replaced my bad coiled COR from the stock 3.0 and put in a 3.4 to match the ECU. My wiring was also a bit different then yours as mine both were 5 pin and identicle units aside for the mount and part numbers were a bit different. Do you have a fuel pump relay aswell? should be under the steering column and none of my wiring shows it but i have one.

When i turn my key to On my pump does not turn on yet when i crank the motor it fires then floods (all cyl's covered plugs in gas). It will fire after sitting and the gas evaperates and i clean the plugs, so i try again and it does it again runs for few seconds revs up high then dies. Im at a loss but i think we have similar problems in a way.

#163

I do not believe I have a fuel pump relay. I can't find one on any of the EWD's I have. I have not physically checked though.

#164

#165

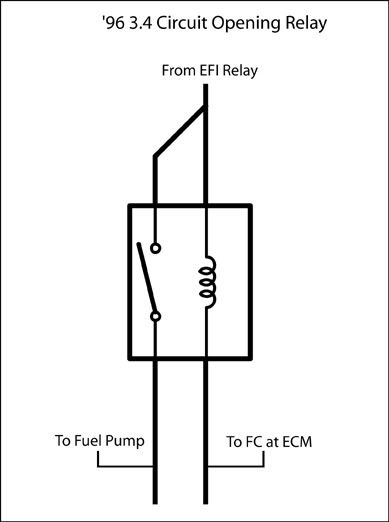

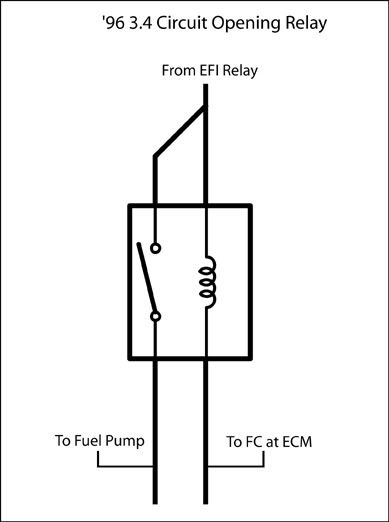

Can anyone help me better understand this relay's operation?

Both inputs from starter and EFI relay are coming from the switched side of their respective relays.

1. What relation does the starter relay side have to the fuel pump relay side? If completely isolated from each other... why are they located in the same relay housing? Save space?

2. Diagonal series of lines on the starter relay side indicates a transistor... correct?

3. What does the starter relay gain from passing through the COR? Does the transistor change something in regards to the ground point that the starter relay is connected to?

Now, just looking at the EFI/ fuel pump side of the 3.0 relay... how does the operation differ from the following relay from the 3.4?

I know the connections go to different locations. But I am just trying to understand if there is any difference in the way the two relays actually operate.

Both inputs from starter and EFI relay are coming from the switched side of their respective relays.

1. What relation does the starter relay side have to the fuel pump relay side? If completely isolated from each other... why are they located in the same relay housing? Save space?

2. Diagonal series of lines on the starter relay side indicates a transistor... correct?

3. What does the starter relay gain from passing through the COR? Does the transistor change something in regards to the ground point that the starter relay is connected to?

Now, just looking at the EFI/ fuel pump side of the 3.0 relay... how does the operation differ from the following relay from the 3.4?

I know the connections go to different locations. But I am just trying to understand if there is any difference in the way the two relays actually operate.

#166

I'll have to look for this relay as well.

I agree with the possibility of your fuel pump connection being incorrect... but am wondering if that might not be related to your flooding issues.

Seems like even if the fuel pump was on all the time, your cylinders wouldn't flood. I am wondering if something is keeping your injectors open or allowing them to shoot more fuel into the cylinders than can be used. Perhaps you are getting fuel consistently through the injectors... but not always the spark needed to burn it up? Just brainstorming.

Seems like even if the fuel pump was on all the time, your cylinders wouldn't flood. I am wondering if something is keeping your injectors open or allowing them to shoot more fuel into the cylinders than can be used. Perhaps you are getting fuel consistently through the injectors... but not always the spark needed to burn it up? Just brainstorming.

#167

Have you converted to the new COR or are you trying to stick with the old? I would try to explain the relay to you but i dont really get it 100% myself. Back in high school I built a Guitar effects pedal from scratch and I new what all the lines meant and were called and even how they worked but ive forgoten the terms and such. but i can still wire

#168

Seems like even if the fuel pump was on all the time, your cylinders wouldn't flood. I am wondering if something is keeping your injectors open or allowing them to shoot more fuel into the cylinders than can be used. Perhaps you are getting fuel consistently through the injectors... but not always the spark needed to burn it up? Just brainstorming.

I did run a code p0100 and p0110 which are both MAF one for circuit malfuntion and the other for Air intake temp which is inside the MAF.

Curious have you checked for codes yet?

#169

I dont know that its your circuit opening relay thats the problem. Your trucks starting function is working and the relay from the 3.0 has two coils in it on is for the starter side the other fuel pump and its switch. Maybe the COR has a bad coil which could be posible and would most likely be the fuel pump side by the way it sounds if that was it. I think you could stick with the old one.

Also i forget if its been said already but when you turn the IGN to on does the pump turn on? Maybe i would try jumping the wires off the COR or before (just a 12v batt power) and see if once you turn the key to start it will fire like it does then continue to stay running. Also when youve got light look for that fuel pump relay casue maybe its doing somthing to us both that we dont know about nor have i heard anything about

Also i forget if its been said already but when you turn the IGN to on does the pump turn on? Maybe i would try jumping the wires off the COR or before (just a 12v batt power) and see if once you turn the key to start it will fire like it does then continue to stay running. Also when youve got light look for that fuel pump relay casue maybe its doing somthing to us both that we dont know about nor have i heard anything about

Last edited by fillsrunner4; 12-10-2007 at 10:36 PM.

#170

I dropped a 3.4 in my 88 toyota pickup 4x4 and it will seem like a nite and day difference in power. Its very easy to cut it loose on the asphalt. But, i also have turbo, and a bunch of other mods to my motor.

#171

Steve,

Nice diagrams; makes it easy to help

1. What relation does the starter relay side have to the fuel pump relay side? If completely isolated from each other... why are they located in the same relay housing? The trigger points are electrically isolated but share the same control point.

2. Diagonal series of lines on the starter relay side indicates a transistor... correct?

No, this is a shunt resistor to bleed off current from the collapsing field of the starter solenoid, I suspect.

3. What does the starter relay gain from passing through the COR? Does the transistor change something in regards to the ground point that the starter relay is connected to?

This is just a control circuit for the fuel pump and the point where the starter signal can operate the fuel pump independently of the MAF on the 3.0

Now, just looking at the EFI/ fuel pump side of the 3.0 relay... how does the operation differ from the following relay from the 3.4?

The 3.4 uses the ECU to control the fuel pump where the 3.0 uses a mechanical switch in the MAF to run the pump.. Same idea, different methodology.

The reason your setup starts and dies is because the fuel pump only runs when the key is in the start position. When you release the key from 'start' to 'on', the relay is de-energized. This is because the 'To AFM' wire isn't going to the the old AFM anymore. In the 3.0 setup, the AFM had a set of contacts on the flapper door that triggered the fuel pump relay when the engine was running. (Air door open at all = path to ground; air door closed / not running = no path to ground). In order to get fuel pressure when cranking, the start signal provides an additional relay closure to run the pump. You need to use the 'To AFM' wire to trigger the pump via the 'To FC at ECM'.. The ECM provides a ground via the 'To FC at ECM' in order to energize the relay. You don't need a diode in this scenario; the factory didn't use one either as the ECU is already using TTL components.

To test the operation, simply ground the 'To AFM' wire with a jumper wire and turn the ignition on. The pump should run and the motor should stay running, barring additional troubles. To test the output of the 'FC at ECM', simply attach a test light to +12v and hook the other side to 'FC at ECM'. The lamp should not light unless the engine is running. I believe it uses the igniter feedback signal to verify the engine operation. DO NOT use the ECU FC wire to run the pump or anything else directly, you will fry the internal transistor in the ECU. That's what the relay is for. A relay typically uses less than 300mA (1/3 amp) on the coil side.

Will

Nice diagrams; makes it easy to help

1. What relation does the starter relay side have to the fuel pump relay side? If completely isolated from each other... why are they located in the same relay housing? The trigger points are electrically isolated but share the same control point.

2. Diagonal series of lines on the starter relay side indicates a transistor... correct?

No, this is a shunt resistor to bleed off current from the collapsing field of the starter solenoid, I suspect.

3. What does the starter relay gain from passing through the COR? Does the transistor change something in regards to the ground point that the starter relay is connected to?

This is just a control circuit for the fuel pump and the point where the starter signal can operate the fuel pump independently of the MAF on the 3.0

Now, just looking at the EFI/ fuel pump side of the 3.0 relay... how does the operation differ from the following relay from the 3.4?

The 3.4 uses the ECU to control the fuel pump where the 3.0 uses a mechanical switch in the MAF to run the pump.. Same idea, different methodology.

The reason your setup starts and dies is because the fuel pump only runs when the key is in the start position. When you release the key from 'start' to 'on', the relay is de-energized. This is because the 'To AFM' wire isn't going to the the old AFM anymore. In the 3.0 setup, the AFM had a set of contacts on the flapper door that triggered the fuel pump relay when the engine was running. (Air door open at all = path to ground; air door closed / not running = no path to ground). In order to get fuel pressure when cranking, the start signal provides an additional relay closure to run the pump. You need to use the 'To AFM' wire to trigger the pump via the 'To FC at ECM'.. The ECM provides a ground via the 'To FC at ECM' in order to energize the relay. You don't need a diode in this scenario; the factory didn't use one either as the ECU is already using TTL components.

To test the operation, simply ground the 'To AFM' wire with a jumper wire and turn the ignition on. The pump should run and the motor should stay running, barring additional troubles. To test the output of the 'FC at ECM', simply attach a test light to +12v and hook the other side to 'FC at ECM'. The lamp should not light unless the engine is running. I believe it uses the igniter feedback signal to verify the engine operation. DO NOT use the ECU FC wire to run the pump or anything else directly, you will fry the internal transistor in the ECU. That's what the relay is for. A relay typically uses less than 300mA (1/3 amp) on the coil side.

Will

Last edited by Willcipher; 12-11-2007 at 05:41 AM.

#172

From the pic in your avatar, one might conclude that you do indeed have headers but the turbo must be 'right bank only' which probably yields less than stellar results

From the pic in your avatar, one might conclude that you do indeed have headers but the turbo must be 'right bank only' which probably yields less than stellar results

Please introduce yourself

in another thread and share some pics, links to other postings, what not because there are only a handful of 3.4 powered rigs pushing over 350 hp and I have only seen a few turbo'd 3.4's in the years I have been surfing.. So, before we all call BS, give us the details (pics, specs, who built it, etc) and an engine shot right away but do so in another thread

in another thread and share some pics, links to other postings, what not because there are only a handful of 3.4 powered rigs pushing over 350 hp and I have only seen a few turbo'd 3.4's in the years I have been surfing.. So, before we all call BS, give us the details (pics, specs, who built it, etc) and an engine shot right away but do so in another thread

Last edited by Willcipher; 12-11-2007 at 05:31 AM.

#173

Thanks for all the help guys.

When I originally turned the key, I had the FC pin from the 3.4 relay tied into the 3.0 COR pin that used to go to the MAF. I figured the MAF switch was completing the circuit and that the FC on the 3.4 ECM would do the same. My motor just starts and stops immediately when key returns to IG2 in this configuration.

I started to think perhaps the 3.0 COR and the 3.4 COR might have something to do with it, but it seems like my connections were correct to the 3.0 COR and the fuel pump should be staying on.

One other thing different between the two systems is that when key is at ST1, the 3.4 starter relay is activated and sends 12v to STA @ 3.4 ECM, starter (Plug A) and a bulb check relay located in the gauge cluster. The 3.4 starter circuit doesn't tie into the 3.4 COR at all, and the only ground point appears to be STA @ the 3.4 ECM. The 3.4 fuel pump is activated only by the FC pin @ the 3.4 ECM.

When key is at ST1 on the 3.0, the starter relay is activated and sends 12v through the COR (activating fuel pump), on to starter (Plug A) and to STA @ 3.0 ECM. There is also a branch to the cold start injector (3.4 has no cold start injector). The 3.0 starter circuit has no interaction to a "bulb check relay". In fact, there doesn't seem to be a "bulb check relay" even in the 3.0 system.

I am wondering if the way the starter ground works on the 3.0 doesn't mesh well with what the 3.4 ECM is looking for. In fact, it seems like the 3.4 ECM controls the ground point for the starter relay.

You can see these two routings in the EWD sections I posted earlier in this thread.

I am going to try and do the following today:

1. Per Willcipher's suggestion, I am going to ground the MAF lead from the 3.0 COR and with key at ST1 see if the fuel pump is running.

2. I will also try to determining if the FC pin @ the 3.4 ECM is completing the ground with a test light.

3. Install the 3.4 COR in place of the 3.0 COR... eliminating the starter activated side of the relay and also eliminating the way the starter is currently grounded. In other words, starter will only get it's ground through STA of the 3.4 ECM and not have a permanent ground to chassis as it does in the 3.0 system.

What do you guys think of all that?

EDIT: And I haven't pulled codes yet as I do not have the OBDII port tied in at this point. In fact, I still have to find an OBDII plug, which I will probably end up ordering through fillsrunner4 online source... cause I can't seem to find one at the salvage yards.

When I originally turned the key, I had the FC pin from the 3.4 relay tied into the 3.0 COR pin that used to go to the MAF. I figured the MAF switch was completing the circuit and that the FC on the 3.4 ECM would do the same. My motor just starts and stops immediately when key returns to IG2 in this configuration.

I started to think perhaps the 3.0 COR and the 3.4 COR might have something to do with it, but it seems like my connections were correct to the 3.0 COR and the fuel pump should be staying on.

One other thing different between the two systems is that when key is at ST1, the 3.4 starter relay is activated and sends 12v to STA @ 3.4 ECM, starter (Plug A) and a bulb check relay located in the gauge cluster. The 3.4 starter circuit doesn't tie into the 3.4 COR at all, and the only ground point appears to be STA @ the 3.4 ECM. The 3.4 fuel pump is activated only by the FC pin @ the 3.4 ECM.

When key is at ST1 on the 3.0, the starter relay is activated and sends 12v through the COR (activating fuel pump), on to starter (Plug A) and to STA @ 3.0 ECM. There is also a branch to the cold start injector (3.4 has no cold start injector). The 3.0 starter circuit has no interaction to a "bulb check relay". In fact, there doesn't seem to be a "bulb check relay" even in the 3.0 system.

I am wondering if the way the starter ground works on the 3.0 doesn't mesh well with what the 3.4 ECM is looking for. In fact, it seems like the 3.4 ECM controls the ground point for the starter relay.

You can see these two routings in the EWD sections I posted earlier in this thread.

I am going to try and do the following today:

1. Per Willcipher's suggestion, I am going to ground the MAF lead from the 3.0 COR and with key at ST1 see if the fuel pump is running.

2. I will also try to determining if the FC pin @ the 3.4 ECM is completing the ground with a test light.

3. Install the 3.4 COR in place of the 3.0 COR... eliminating the starter activated side of the relay and also eliminating the way the starter is currently grounded. In other words, starter will only get it's ground through STA of the 3.4 ECM and not have a permanent ground to chassis as it does in the 3.0 system.

What do you guys think of all that?

EDIT: And I haven't pulled codes yet as I do not have the OBDII port tied in at this point. In fact, I still have to find an OBDII plug, which I will probably end up ordering through fillsrunner4 online source... cause I can't seem to find one at the salvage yards.

Last edited by Elvota; 12-11-2007 at 07:39 AM.

#174

However, there is an absolutely huge chance of burning to death in an accident with a fuel pump running non-stop with the ignition on, fuel line separated from the non-running engine and squirting into the cab after a rollover. The pump should be run with engine off for testing purposes only; hardwiring it to the ignition is a terrible idea and the consequences could include death in the right situation.

However, there is an absolutely huge chance of burning to death in an accident with a fuel pump running non-stop with the ignition on, fuel line separated from the non-running engine and squirting into the cab after a rollover. The pump should be run with engine off for testing purposes only; hardwiring it to the ignition is a terrible idea and the consequences could include death in the right situation.

#175

Thanks for all the help guys.

When I originally turned the key, I had the FC pin from the 3.4 relay tied into the 3.0 COR pin that used to go to the MAF. I figured the MAF switch was completing the circuit and that the FC on the 3.4 ECM would do the same. My motor just starts and stops immediately when key returns to IG2 in this configuration.

I started to think perhaps the 3.0 COR and the 3.4 COR might have something to do with it, but it seems like my connections were correct to the 3.0 COR and the fuel pump should be staying on.

One other thing different between the two systems is that when key is at ST1, the 3.4 starter relay is activated and sends 12v to STA @ 3.4 ECM, starter (Plug A) and a bulb check relay located in the gauge cluster. The 3.4 starter circuit doesn't tie into the 3.4 COR at all, and the only ground point appears to be STA @ the 3.4 ECM. The 3.4 fuel pump is activated only by the FC pin @ the 3.4 ECM.

When key is at ST1 on the 3.0, the starter relay is activated and sends 12v through the COR (activating fuel pump), on to starter (Plug A) and to STA @ 3.0 ECM. There is also a branch to the cold start injector (3.4 has no cold start injector). The 3.0 starter circuit has no interaction to a "bulb check relay". In fact, there doesn't seem to be a "bulb check relay" even in the 3.0 system.

I am wondering if the way the starter ground works on the 3.0 doesn't mesh well with what the 3.4 ECM is looking for. In fact, it seems like the 3.4 ECM controls the ground point for the starter relay.

You can see these two routings in the EWD sections I posted earlier in this thread.

I am going to try and do the following today:

1. Per Willcipher's suggestion, I am going to ground the MAF lead from the 3.0 COR and with key at ST1 see if the fuel pump is running.

2. I will also try to determining if the FC pin @ the 3.4 ECM is completing the ground with a test light.

3. Install the 3.4 COR in place of the 3.0 COR... eliminating the starter activated side of the relay and also eliminating the way the starter is currently grounded. In other words, starter will only get it's ground through STA of the 3.4 ECM and not have a permanent ground to chassis as it does in the 3.0 system.

What do you guys think of all that?

EDIT: And I haven't pulled codes yet as I do not have the OBDII port tied in at this point. In fact, I still have to find an OBDII plug, which I will probably end up ordering through fillsrunner4 online source... cause I can't seem to find one at the salvage yards.

When I originally turned the key, I had the FC pin from the 3.4 relay tied into the 3.0 COR pin that used to go to the MAF. I figured the MAF switch was completing the circuit and that the FC on the 3.4 ECM would do the same. My motor just starts and stops immediately when key returns to IG2 in this configuration.

I started to think perhaps the 3.0 COR and the 3.4 COR might have something to do with it, but it seems like my connections were correct to the 3.0 COR and the fuel pump should be staying on.

One other thing different between the two systems is that when key is at ST1, the 3.4 starter relay is activated and sends 12v to STA @ 3.4 ECM, starter (Plug A) and a bulb check relay located in the gauge cluster. The 3.4 starter circuit doesn't tie into the 3.4 COR at all, and the only ground point appears to be STA @ the 3.4 ECM. The 3.4 fuel pump is activated only by the FC pin @ the 3.4 ECM.

When key is at ST1 on the 3.0, the starter relay is activated and sends 12v through the COR (activating fuel pump), on to starter (Plug A) and to STA @ 3.0 ECM. There is also a branch to the cold start injector (3.4 has no cold start injector). The 3.0 starter circuit has no interaction to a "bulb check relay". In fact, there doesn't seem to be a "bulb check relay" even in the 3.0 system.

I am wondering if the way the starter ground works on the 3.0 doesn't mesh well with what the 3.4 ECM is looking for. In fact, it seems like the 3.4 ECM controls the ground point for the starter relay.

You can see these two routings in the EWD sections I posted earlier in this thread.

I am going to try and do the following today:

1. Per Willcipher's suggestion, I am going to ground the MAF lead from the 3.0 COR and with key at ST1 see if the fuel pump is running.

2. I will also try to determining if the FC pin @ the 3.4 ECM is completing the ground with a test light.

3. Install the 3.4 COR in place of the 3.0 COR... eliminating the starter activated side of the relay and also eliminating the way the starter is currently grounded. In other words, starter will only get it's ground through STA of the 3.4 ECM and not have a permanent ground to chassis as it does in the 3.0 system.

What do you guys think of all that?

EDIT: And I haven't pulled codes yet as I do not have the OBDII port tied in at this point. In fact, I still have to find an OBDII plug, which I will probably end up ordering through fillsrunner4 online source... cause I can't seem to find one at the salvage yards.

I think you should leave the original COR in place for simplicity.. You need to confirm the relay coil terminals with a DMM and ensure power is at one side with ignition on and it only needs a ground to trigger the pump. I figured the relay triggering in the start position is like a built in diagnosis function. I used the original COR and, IIRC, I pulled one spade terminal from the COR and popped another in place that goes straight to the 3.4 ECU.. Sorry, my recollection is foggy as it's been like 4 1/2 years since I did it

Will

#176

Not deliberately trying to lambaste you...  However, there is an absolutely huge chance of burning to death in an accident with a fuel pump running non-stop with the ignition on, fuel line separated from the non-running engine and squirting into the cab after a rollover. The pump should be run with engine off for testing purposes only; hardwiring it to the ignition is a terrible idea and the consequences could include death in the right situation.

However, there is an absolutely huge chance of burning to death in an accident with a fuel pump running non-stop with the ignition on, fuel line separated from the non-running engine and squirting into the cab after a rollover. The pump should be run with engine off for testing purposes only; hardwiring it to the ignition is a terrible idea and the consequences could include death in the right situation.

However, there is an absolutely huge chance of burning to death in an accident with a fuel pump running non-stop with the ignition on, fuel line separated from the non-running engine and squirting into the cab after a rollover. The pump should be run with engine off for testing purposes only; hardwiring it to the ignition is a terrible idea and the consequences could include death in the right situation.

However, there is an absolutely huge chance of burning to death in an accident with a fuel pump running non-stop with the ignition on, fuel line separated from the non-running engine and squirting into the cab after a rollover. The pump should be run with engine off for testing purposes only; hardwiring it to the ignition is a terrible idea and the consequences could include death in the right situation.I don't think we were concerned if I burnt to death... just concerned getting this thing running. But good for us all to know that a possible fiery catastrophe awaits us if we wire the fuel pump to a switch outside the ignition control.

#177

another thing- You can use any OBDII plug from any post 96 vehicle; mine is actually from a Dodge Intrepid. Grab one from 96- up Corolla next time you're there. Wiring for all Asian vehicles is the same.

#178