Elvota's 3.4 swap

#222

Good job!

Good job!Hopefully you can get the loose ends tied up and come on out for Martinez. That would be a great all around test for the new power plant I would imagine. I'm sure it would do great. Of course you'd have plenty of assistance if anything arose.

#223

I'd like to run 404 soon, and I know you haven't been out there. Let's make it happen if my truck keeps coming together.

Don't want anyone to have to deal with my swap issues on a trail day.... but I know you guys would definitely help. You'd have to, I'd be sure to go first and block the trail if things went south.

#226

Indeed.

Thanks. No update just yet. I should be able to actually drive it around tonight. Then barring any issues, I'll change the sig.

#227

[QUOTE=Elvota;50694394]

Actually, I was going through the FSM testing procedure I had so graciously been E-Mailed behind the scenes, starting to look for continuity. Suddenly, the IGC2 signal wire from the ECM to coil No.3 looked bad.

For those who don't know, the ignitor plug is a well sealed unit. A little rubber grommet at the entrance of each wire to the plug. Nothing more than the slightest tug and the troubled orange wire just slipped right out. To think, orange is even my favorite color.

Anyway, after struggling with the pin forever, I was finally able to reconnect this little so and so and turn the key to instant fire up. Coolest thing is the issue wasn't even something I did wrong or forgot to do. Very stoked, very stoked indeed.

QUOTE]

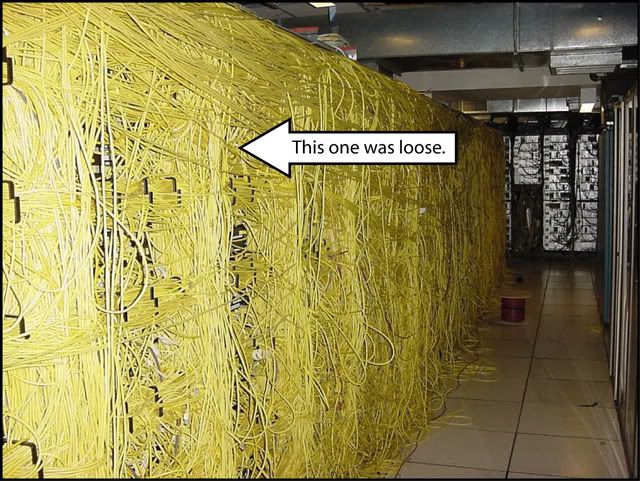

Congrats, glad you got it figured out Nothing quite like the satisfaction of analyzing a problem from every angle and ultimately solving it. I especially like your attached pic- I used to work in AT&T's central offices and they tended to look alot like the spaghetti mess above (granted that's just a Cat5 patch panel); orders for new fiber and coax would come in and the installers would 'tag and dangle' cabling and mix it in with the old stuff.. Problem was, the old unused stuff would just build up because the removal of it could possibly disrupt a customer's connection.

Nothing quite like the satisfaction of analyzing a problem from every angle and ultimately solving it. I especially like your attached pic- I used to work in AT&T's central offices and they tended to look alot like the spaghetti mess above (granted that's just a Cat5 patch panel); orders for new fiber and coax would come in and the installers would 'tag and dangle' cabling and mix it in with the old stuff.. Problem was, the old unused stuff would just build up because the removal of it could possibly disrupt a customer's connection.

On the subject of gratuitous troubleshooting, I recently purchased a 96 Maxima on the cheap with a serious intermittent starting problem. Sometimes it would start fine, other times it would crank and crank and ultimately flood the engine. It would be safe to say you couldn't drive this car any further than you wanted to walk.

The previous owner spent tons of money at a shop and they replaced the following: battery, starter, ignition switch, and fuel pump. None of this, of course had anything to do with the trouble. I discovered a bad cam sensor (had a code), replaced it and got less failed starts but still some trouble starting. After a little research on maximas.org, I discovered the possibility of a bad body/drivetrain ground. I immediately cleaned the ground connections with a 3M greenie and it has started like a new car ever since The previous owner and the shop could've saved tons of time and money buy poking around on the internet for real solutions.

The previous owner and the shop could've saved tons of time and money buy poking around on the internet for real solutions.

Anyway, I'm expecting a nice 6 pack of natty light or milwaukee's beast from you now

Will

Actually, I was going through the FSM testing procedure I had so graciously been E-Mailed behind the scenes, starting to look for continuity. Suddenly, the IGC2 signal wire from the ECM to coil No.3 looked bad.

For those who don't know, the ignitor plug is a well sealed unit. A little rubber grommet at the entrance of each wire to the plug. Nothing more than the slightest tug and the troubled orange wire just slipped right out. To think, orange is even my favorite color.

Anyway, after struggling with the pin forever, I was finally able to reconnect this little so and so and turn the key to instant fire up. Coolest thing is the issue wasn't even something I did wrong or forgot to do. Very stoked, very stoked indeed.

QUOTE]

Congrats, glad you got it figured out

Nothing quite like the satisfaction of analyzing a problem from every angle and ultimately solving it. I especially like your attached pic- I used to work in AT&T's central offices and they tended to look alot like the spaghetti mess above (granted that's just a Cat5 patch panel); orders for new fiber and coax would come in and the installers would 'tag and dangle' cabling and mix it in with the old stuff.. Problem was, the old unused stuff would just build up because the removal of it could possibly disrupt a customer's connection.

Nothing quite like the satisfaction of analyzing a problem from every angle and ultimately solving it. I especially like your attached pic- I used to work in AT&T's central offices and they tended to look alot like the spaghetti mess above (granted that's just a Cat5 patch panel); orders for new fiber and coax would come in and the installers would 'tag and dangle' cabling and mix it in with the old stuff.. Problem was, the old unused stuff would just build up because the removal of it could possibly disrupt a customer's connection.

On the subject of gratuitous troubleshooting, I recently purchased a 96 Maxima on the cheap with a serious intermittent starting problem. Sometimes it would start fine, other times it would crank and crank and ultimately flood the engine. It would be safe to say you couldn't drive this car any further than you wanted to walk.

The previous owner spent tons of money at a shop and they replaced the following: battery, starter, ignition switch, and fuel pump. None of this, of course had anything to do with the trouble. I discovered a bad cam sensor (had a code), replaced it and got less failed starts but still some trouble starting. After a little research on maximas.org, I discovered the possibility of a bad body/drivetrain ground. I immediately cleaned the ground connections with a 3M greenie and it has started like a new car ever since

The previous owner and the shop could've saved tons of time and money buy poking around on the internet for real solutions.

The previous owner and the shop could've saved tons of time and money buy poking around on the internet for real solutions. Anyway, I'm expecting a nice 6 pack of natty light or milwaukee's beast from you now

Will

Last edited by Willcipher; 12-14-2007 at 06:40 AM.

#228

Well, endless loose ends to work through today... but still actually haven't been able to drive it. Had it idling for a while finally by the end of the day, but one of the rear heater lines started to leak. I tried a few things, even a complete bypass... but no luck.

Hopefully I'll have some time tomorrow to finish it off.

My list is down to bleeding the clutch and now getting my heater lines to work.

Hopefully I'll have some time tomorrow to finish it off.

My list is down to bleeding the clutch and now getting my heater lines to work.

#230

Well, endless loose ends to work through today... but still actually haven't been able to drive it. Had it idling for a while finally by the end of the day, but one of the rear heater lines started to leak. I tried a few things, even a complete bypass... but no luck.

Hopefully I'll have some time tomorrow to finish it off.

My list is down to bleeding the clutch and now getting my heater lines to work.

Hopefully I'll have some time tomorrow to finish it off.

My list is down to bleeding the clutch and now getting my heater lines to work.

lol its good to hear its running though

now to make mine run is a different story but hopefully by end of next week. ill keep you informed

now to make mine run is a different story but hopefully by end of next week. ill keep you informed

#232

Well.... doesn't that just figure..

Got everything done today. No leaks, idles fine, everything appeared good to go.

Even cut the hood:

So then I spent the next hour plus bleeding and re-bleeding and bleeding the clutch again. No air, yet every time I push in the pedal, I can't get it in gear. No way... no how. Just grinds and grinds.

So here I am, swap done, engine ready to go... and I still can't even get out the driveway.

There must be something wrong inside the clutch. Which means I have to pull the tranny, but first the sticks, and the exhaust, and the driveshafts. Dang does that sound like a lot of work I really, really, really don't want to do again.

Thing is I am not really sure what I did wrong. I used the 3.4 pressure plate, clutch and pilot bearing... but used the 3.0 throwout bearing. It was my understanding that the 3.4 bearing wouldn't work. I figured something might have been amiss with how hard it was to get back together.

If I push in the pedal, but the pressure plate doesn't move... what might the cause be? Any guesses?

This project is starting to kick my ass.

Even cut the hood:

So then I spent the next hour plus bleeding and re-bleeding and bleeding the clutch again. No air, yet every time I push in the pedal, I can't get it in gear. No way... no how. Just grinds and grinds.

So here I am, swap done, engine ready to go... and I still can't even get out the driveway.

There must be something wrong inside the clutch. Which means I have to pull the tranny, but first the sticks, and the exhaust, and the driveshafts. Dang does that sound like a lot of work I really, really, really don't want to do again.

Thing is I am not really sure what I did wrong. I used the 3.4 pressure plate, clutch and pilot bearing... but used the 3.0 throwout bearing. It was my understanding that the 3.4 bearing wouldn't work. I figured something might have been amiss with how hard it was to get back together.

If I push in the pedal, but the pressure plate doesn't move... what might the cause be? Any guesses?

This project is starting to kick my ass.

Last edited by Elvota; 01-10-2008 at 11:21 AM.

#234

#235

Is it hard to push the clutch in? Maybe not all 3.0 thowout bearings are short. Mines for an 88 R150f and it was alot shorter than the 3.4 one i bought from Marlin but i dont know if all are short. That could be your problem if the clutch is only partialy engaged and if its hard to press the clutch all the way that would be my guess. Measure the bearing if its 2.5" then its too long.

#236

It's very strange actually. I think I remember you saying your clutch felt stiff when you got it all back together, and after struggling with mine I felt like I had a 50/50 chance ending up with the same problem.

Thing is, clutch "feels" fine. Action is smooth, pedal goes to the floor easily. I watch the slave and it moves well, no interference what so ever. But the pressure plate never looses friction... when I try to go into gear, I just get noise. Maybe even a little forward surge. Very light, I don't force the stick.

Could be the bearing, or maybe I did something stupid like put the plate in backwards. That's all I can think of, but it sure doesn't work now.

Would this be from end to end of the bearing? When I pull it, I can measure it.

Thing is, clutch "feels" fine. Action is smooth, pedal goes to the floor easily. I watch the slave and it moves well, no interference what so ever. But the pressure plate never looses friction... when I try to go into gear, I just get noise. Maybe even a little forward surge. Very light, I don't force the stick.

Could be the bearing, or maybe I did something stupid like put the plate in backwards. That's all I can think of, but it sure doesn't work now.

Would this be from end to end of the bearing? When I pull it, I can measure it.

#237

It's very strange actually. I think I remember you saying your clutch felt stiff when you got it all back together, and after struggling with mine I felt like I had a 50/50 chance ending up with the same problem.

Thing is, clutch "feels" fine. Action is smooth, pedal goes to the floor easily. I watch the slave and it moves well, no interference what so ever. But the pressure plate never looses friction... when I try to go into gear, I just get noise. Maybe even a little forward surge. Very light, I don't force the stick.

Could be the bearing, or maybe I did something stupid like put the plate in backwards. That's all I can think of, but it sure doesn't work now.

Would this be from end to end of the bearing? When I pull it, I can measure it.

Thing is, clutch "feels" fine. Action is smooth, pedal goes to the floor easily. I watch the slave and it moves well, no interference what so ever. But the pressure plate never looses friction... when I try to go into gear, I just get noise. Maybe even a little forward surge. Very light, I don't force the stick.

Could be the bearing, or maybe I did something stupid like put the plate in backwards. That's all I can think of, but it sure doesn't work now.

Would this be from end to end of the bearing? When I pull it, I can measure it.

#238

If the bearing is long, wouldn't that make the clutch never engage? Wouldn't it be like your pedal is down all the time?

My problem feels like the bearing isn't pushing on the clutch, or the clutch isn't releasing, maybe bound up... but what ever would cause that?

#239

Now we're rolling...

Figured out my clutch problem tonight. Evidently, I can swap in a 3.4 with a chopped harness into my '90 4Runner, but can't do a clutch job.

As I said, I couldn't get it in gear, made a bunch of noise and just "felt" wrong. I knew it was something I had done, and I knew that tranny was a major pain to get back on last time.

So, looking at re-doing a job I had just done and a running 3.4 that hadn't moved a foot yet... I decided to make a game of it and went for time. Much to my surprise, I got the tranny off, clutch apart, fixed the issue... and bolted all back together in 5 hours. That's very fast for me. I was determined to drive this thing no matter what.

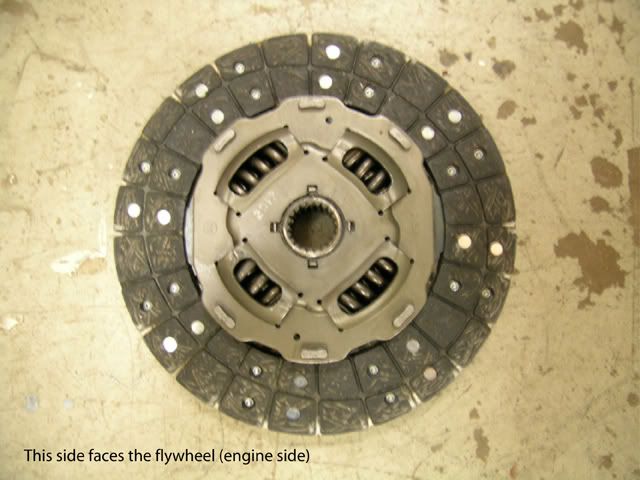

Ever wondered if you could put the pressure plate in backwards at get away with it? Well, you can... until you actually try to put it in gear. I know cause that's what I was foolish enough to do, I put my clutch together wrong side out.

I took some pics and will post them in an effort to stop someone from doing what I did... even though it's fairly obvious if I had taken some time to really look.

From the side, the deeper section of the center spring assembly of the pressure plate faces the flywheel.

View from the face:

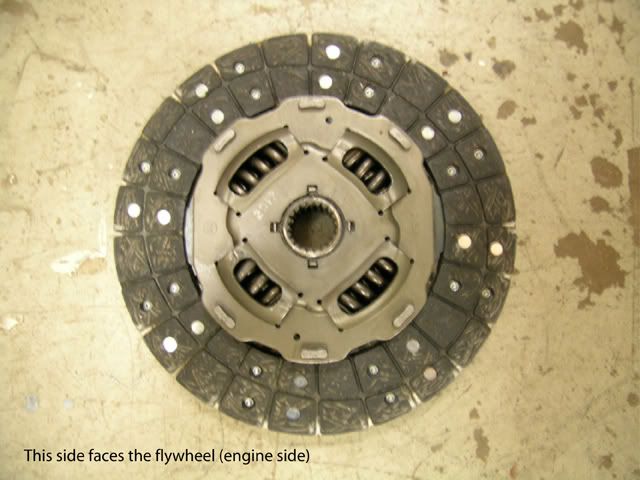

This of course means the thinner side faces the clutch itself:

If you look real close you can see the engine side has more of a wavy rectangular shape stamped in the steel.

Dumb mistake, but when all is said and done I actually got to go for a drive tonight. That was sweeeeeet!!!

I must say, that 3.4 pulls really, really well. So much more torque than before and strong all the way through till I have to grab the next gear. Engine temp was good, checked for leaks and found none. Power steering works much better than before as well, but I think my 3.0 had a pump on it's way out. I do feel the steering shaft "tick" off the alternator housing on occasion. I'll have to address that.

This will be news to no one, but this swap is a great way to go. I only wish I had done it sooner, but really don't think I was mechanically ready until now.

As I said, I couldn't get it in gear, made a bunch of noise and just "felt" wrong. I knew it was something I had done, and I knew that tranny was a major pain to get back on last time.

So, looking at re-doing a job I had just done and a running 3.4 that hadn't moved a foot yet... I decided to make a game of it and went for time. Much to my surprise, I got the tranny off, clutch apart, fixed the issue... and bolted all back together in 5 hours. That's very fast for me. I was determined to drive this thing no matter what.

Ever wondered if you could put the pressure plate in backwards at get away with it? Well, you can... until you actually try to put it in gear. I know cause that's what I was foolish enough to do, I put my clutch together wrong side out.

I took some pics and will post them in an effort to stop someone from doing what I did... even though it's fairly obvious if I had taken some time to really look.

From the side, the deeper section of the center spring assembly of the pressure plate faces the flywheel.

View from the face:

This of course means the thinner side faces the clutch itself:

If you look real close you can see the engine side has more of a wavy rectangular shape stamped in the steel.

Dumb mistake, but when all is said and done I actually got to go for a drive tonight. That was sweeeeeet!!!

I must say, that 3.4 pulls really, really well. So much more torque than before and strong all the way through till I have to grab the next gear. Engine temp was good, checked for leaks and found none. Power steering works much better than before as well, but I think my 3.0 had a pump on it's way out. I do feel the steering shaft "tick" off the alternator housing on occasion. I'll have to address that.

This will be news to no one, but this swap is a great way to go. I only wish I had done it sooner, but really don't think I was mechanically ready until now.

#240

Could there truly be so few wires???

All right, the wiring.

Of course, all swaps will be a little different... but this is my swap, so take what you can from it and run.

Basically, the 3.4 ECM and the 3.4 motor work as a team. They don't care in what vehicle they are mounted. Just give them air, fuel, coolant... and you'll have a very happy couple.

Then your vehicle needs to be told some information so you can see what's going on through your various gauges. Of course, that step could even be skipped. The 3.4 doesn't care if you know what's going on after all.

One thing the ECM also needs is power. That is provided from the original 3.0 body harness. How it gets this power is important, as other related '90 components need to be told what to do as well

These are the wires I hooked up:

IG2 from the '90 to the IG2 circuit wires from the 3.4 harness.

Engine coolant sensor from the 3.4 harness to the '90 wire from the temp gauge.

Oil pressure sender from the 3.4 harness to the '90 wire for the pressure gauge. (note, '90 pressure sender is used on the 3.4)

Indicator lamp pin from 3.4 ECM connected to the '90 gauge indicator lamp wire.

Stop light switch from the '90 to the 3.4 ECM stop light pin.

Speed sensor from the '90 gauge to the 3.4 ECM.

3.4 ECM circuit start relay pin to the circuit start relay on the '90.

3.4 EFI relay pin to the EFI relay on the '90.

And that's almost it.

I ran a new wire from the STA pin on the 3.4 ECM to the starter itself. That particular wire got lost in the '90 harness for me.

I haven't done the AC yet, but have pulled the wires from the AC amplifier and related from the '90 as well as the 3.4 ECM so I can connect them when I figure that out.

I still need to do the 10ohm tach mod so the '90 tach can handle the 3.4 signal, but that wire is marked from the 3.4 ignitor and just needs to be connected.

There is one pin from the 3.4 ECM that is for the OBDII port. 4 wires in total need to go to the port. Second is a ground from the DS intake, third is a standard body ground and the last is a 12v power supply with a 7.5a fuse. I still need the port, but have all the wires to plug into it when I get one. And as I have learned, any vehicle post '96 will have one that I can use.

I left the 4WD, cruise control and ADD pins disconnected from the 3.4 ECM as I did not need them.

You'll probably find as I did that many of the systems between the 3.4 equipped vehicles and the 3.0 equipped vehicles are very similiar. Of course, the newer the 3.4 you get the farther the two systems will be apart. If you have the Toyota factory EWD from both your donor vehicle and current vehicle most of the pieces are fairly easy to figure out. Patience and accuracy is the key.

You may also find that 95% of the 3.4 ECM to the '90 connections are located in one plug, plug D. Also, 95% of the connections you'll need from the '90 are right there in the PS kick panel by the original ECM. Plug IH1 and IH2 had almost all I needed to connect to.

If I did a swap again and found a donor with a uncut harness I'd have been miles ahead. Adding a supercharger or an automatic into the equation would surely complicate things, but I'd imagine still something that could be handled.

Mind you, I am just fine sticking with the complexity of the 5spd swap... that was hard enough.

Of course, all swaps will be a little different... but this is my swap, so take what you can from it and run.

Basically, the 3.4 ECM and the 3.4 motor work as a team. They don't care in what vehicle they are mounted. Just give them air, fuel, coolant... and you'll have a very happy couple.

Then your vehicle needs to be told some information so you can see what's going on through your various gauges. Of course, that step could even be skipped. The 3.4 doesn't care if you know what's going on after all.

One thing the ECM also needs is power. That is provided from the original 3.0 body harness. How it gets this power is important, as other related '90 components need to be told what to do as well

These are the wires I hooked up:

IG2 from the '90 to the IG2 circuit wires from the 3.4 harness.

Engine coolant sensor from the 3.4 harness to the '90 wire from the temp gauge.

Oil pressure sender from the 3.4 harness to the '90 wire for the pressure gauge. (note, '90 pressure sender is used on the 3.4)

Indicator lamp pin from 3.4 ECM connected to the '90 gauge indicator lamp wire.

Stop light switch from the '90 to the 3.4 ECM stop light pin.

Speed sensor from the '90 gauge to the 3.4 ECM.

3.4 ECM circuit start relay pin to the circuit start relay on the '90.

3.4 EFI relay pin to the EFI relay on the '90.

And that's almost it.

I ran a new wire from the STA pin on the 3.4 ECM to the starter itself. That particular wire got lost in the '90 harness for me.

I haven't done the AC yet, but have pulled the wires from the AC amplifier and related from the '90 as well as the 3.4 ECM so I can connect them when I figure that out.

I still need to do the 10ohm tach mod so the '90 tach can handle the 3.4 signal, but that wire is marked from the 3.4 ignitor and just needs to be connected.

There is one pin from the 3.4 ECM that is for the OBDII port. 4 wires in total need to go to the port. Second is a ground from the DS intake, third is a standard body ground and the last is a 12v power supply with a 7.5a fuse. I still need the port, but have all the wires to plug into it when I get one. And as I have learned, any vehicle post '96 will have one that I can use.

I left the 4WD, cruise control and ADD pins disconnected from the 3.4 ECM as I did not need them.

You'll probably find as I did that many of the systems between the 3.4 equipped vehicles and the 3.0 equipped vehicles are very similiar. Of course, the newer the 3.4 you get the farther the two systems will be apart. If you have the Toyota factory EWD from both your donor vehicle and current vehicle most of the pieces are fairly easy to figure out. Patience and accuracy is the key.

You may also find that 95% of the 3.4 ECM to the '90 connections are located in one plug, plug D. Also, 95% of the connections you'll need from the '90 are right there in the PS kick panel by the original ECM. Plug IH1 and IH2 had almost all I needed to connect to.

If I did a swap again and found a donor with a uncut harness I'd have been miles ahead. Adding a supercharger or an automatic into the equation would surely complicate things, but I'd imagine still something that could be handled.

Mind you, I am just fine sticking with the complexity of the 5spd swap... that was hard enough.

Last edited by Elvota; 12-15-2007 at 11:26 PM.