Ring gear size????

#21

Registered User

Join Date: Feb 2006

Location: Barrie, Ontario CANADA

Posts: 1,730

Likes: 0

Received 0 Likes

on

0 Posts

Are you sure that the wheels are causing the sound. There is some play in the axel because the bearings are pressed on. Even new ones have play in them, they have to. They are not like regular wheel bearings that sit in a sandwitched cup. These are just like normal roller bearings. Depending on the size of the tire that you are grabing onto the more play there may appear to be. I don't think you would get a wak wak wak from a bad bearing situation you would get a howl or grinding noise. Are you sure the noise is not farther foward in the driveline? Clutch problem?

#22

Contributing Member

If you're going to rebuild the diff, you should probably just get a "master install kit". The Genuine Gear ones from 4WP are actually very good (even according to Zuk, who hates their gears) and very reasonably priced. It will include all the bearings, seals, and whatever else you need to replace while you got it taken apart.

All that said, the chances of that causing the wheel to wobble are pretty slight. I agree with their prognosis of bent axle or bad wheel bearing. Get it fixed soon - that pressed on wheel bearing is the onlt thing holding the axle in. You don't want to end up like this:

All that said, the chances of that causing the wheel to wobble are pretty slight. I agree with their prognosis of bent axle or bad wheel bearing. Get it fixed soon - that pressed on wheel bearing is the onlt thing holding the axle in. You don't want to end up like this:

#23

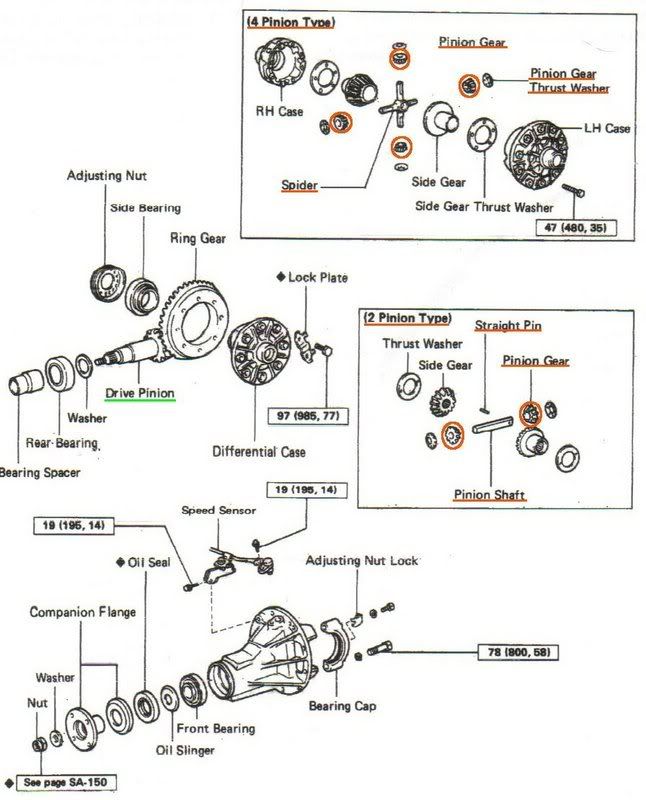

The 2 pinion differentials, 7.5" and 8", have 2 pinion gears that interact with the side gears. They ride on a pinion shaft.

The 4 pinion differential, 8" and larger, has 4 pinion gears that interact with the side gears. These ride on a spider. The term spider gears is derived from this peice.

Side gear backlash is a measure between a side gear and the 2 or 4 pinions, respectively. And is adjusted by side gear thrust washer thickness.

#24

And ... The verdict is that my Side Gears cannot be "adjusted" since they have worn themselves into the case. So a $$$$$$$$$$$$$600 quote was dished out to rebuild the 3rd member bearings and all.

I am apalled. There has got to be a better (more economical way) of getting this truck back on the road.

And so i'd like to weigh out all my options before shaking the piggy bank.

I'm seriously thinking about getting a salvaged member from a compatable donor. To my knowledge, anything with a bearing from a yard is a bad idea. So, Let me make sure i have this straight. I can buy a used member from ANY toyota 8" ring geared axle w/out ABS and as long as she has 10 stud holes, i can bolt her right up to my 4 cyl pickup no problemo?

Low miles of course.

All input greatly appreciated.

I am apalled. There has got to be a better (more economical way) of getting this truck back on the road.

And so i'd like to weigh out all my options before shaking the piggy bank.

I'm seriously thinking about getting a salvaged member from a compatable donor. To my knowledge, anything with a bearing from a yard is a bad idea. So, Let me make sure i have this straight. I can buy a used member from ANY toyota 8" ring geared axle w/out ABS and as long as she has 10 stud holes, i can bolt her right up to my 4 cyl pickup no problemo?

Low miles of course.

All input greatly appreciated.

Last edited by Itoyota; 07-30-2007 at 05:36 PM. Reason: Grace

#25

And just to repeat myself. Trust me when i say, i have exhausted all other options before turning to the third member for the root cause of the problem. I have replaced u joints, entire drivers side axel shaft and NEW wheel bearing, and yet when mounted on TORQUED. The wheel has a slight tick tick when rocked in any direction perpendicular to direction of travel. And TRUE the wheel bearing and c clip might be the only things holding IN the axle shaft( that is into the housing) BUT, not ALL of the weight is carried there. It is shared at the diff as well, otherwise you'd have a miniature sea saw pivoting on one pont.

#26

Yes, any 8" will work. Even the ABS, you'd just have to leave it disconnected. But you can probably find one that's good somewhere, I did. You might also consider grabbing the 4 pinion 3rd off a V6 pickup/4Runner. They are totally interchangeable with the stuff you have and a little stronger/longer lasting. Not if you want to use your 4 cyl ring & pinion though(they're still good right?). That would take another step, so keep them for spares anyway.

Last edited by MudHippy; 07-30-2007 at 06:26 PM.

#28

My luck just keeps slipping downhill. Most of the yards around here won't sell the third member off any truck/4 runner. They'll go whole rear end for 200 and now that 1/2 the axle is new, i really don't wanna. man.

And if i changed the gear ratio. lets say from a 4.1 2 pinion 4cyl (stock) to a 4. x>1 ratio w/ 4 pinions that belong on a v6. Are we talking power loss? power gain? I know ring and pinion have a hella lot to do with torque. I have 31x11.5 that aren't on thanks to the gas prices, but would swapping up in pinion ratio 4.3 4.6 or swapping down be better?

And if i changed the gear ratio. lets say from a 4.1 2 pinion 4cyl (stock) to a 4. x>1 ratio w/ 4 pinions that belong on a v6. Are we talking power loss? power gain? I know ring and pinion have a hella lot to do with torque. I have 31x11.5 that aren't on thanks to the gas prices, but would swapping up in pinion ratio 4.3 4.6 or swapping down be better?

#29

Contributing Member

Yes, swapping to lower gears will help get your mileage back with the 31's. The factory gearing with the 31's was 4.56 for manual tranny, 4.88 for auto.

Seriously - the money you're looking at would get you a Detroit locker, a TruTrac limited slip, and a helluva chunk out of an ARB - all of which totally replace the carrier assembly.

You can also buy preassembled thirdmembers from Marlin Crawler, TrailGear, Inchworm, and Randy's Ring and Pinion for pretty reasonable prices.

Seriously - the money you're looking at would get you a Detroit locker, a TruTrac limited slip, and a helluva chunk out of an ARB - all of which totally replace the carrier assembly.

You can also buy preassembled thirdmembers from Marlin Crawler, TrailGear, Inchworm, and Randy's Ring and Pinion for pretty reasonable prices.

#30

Registered User

Join Date: Mar 2004

Location: Salem,Oregon

Posts: 511

Likes: 0

Received 0 Likes

on

0 Posts

Where are you at??

Sounds like you are getting the run around. Just for clarification if your wheel has any wobbling issues then its the wheel bearing in the end of the axle as the diff has no control over that. There is plenty of play (slop) in the diff even when everything is fine. Carrier bearings rarely have any problem its usually the pinion bearings that die first. Sounds to me like you need to pull the 3rd member out for inspection if everything looks good just tighten up the carrier bearing pre load and put it back in.

here are a few links to what I consider the best differential information around.

tightening up carrier bearings... http://gearinstalls.com/freshen.htm

main Page... http://gearinstalls.com/

List your location and I'm sure you can find some one to help you out.

Sounds like you are getting the run around. Just for clarification if your wheel has any wobbling issues then its the wheel bearing in the end of the axle as the diff has no control over that. There is plenty of play (slop) in the diff even when everything is fine. Carrier bearings rarely have any problem its usually the pinion bearings that die first. Sounds to me like you need to pull the 3rd member out for inspection if everything looks good just tighten up the carrier bearing pre load and put it back in.

here are a few links to what I consider the best differential information around.

tightening up carrier bearings... http://gearinstalls.com/freshen.htm

main Page... http://gearinstalls.com/

List your location and I'm sure you can find some one to help you out.

#31

Registered User

Where are you at??

Sounds like you are getting the run around. Just for clarification if your wheel has any wobbling issues then its the wheel bearing in the end of the axle as the diff has no control over that. There is plenty of play (slop) in the diff even when everything is fine. Carrier bearings rarely have any problem its usually the pinion bearings that die first.

Sounds like you are getting the run around. Just for clarification if your wheel has any wobbling issues then its the wheel bearing in the end of the axle as the diff has no control over that. There is plenty of play (slop) in the diff even when everything is fine. Carrier bearings rarely have any problem its usually the pinion bearings that die first.

Dont confuse the carrier bearings with carrier side gears and carrier wear. We also call the carrier the differential case. I've never seen a worn carrier bearing, I HAVE seen worn carrier (my own). The axle pivots on the bearing in the beearing case. Thats how you get the 'tink tink tink' sound from the third. The axle should not pivot AT ALL.

The axle bearings life is speed up tremendoulsy when the carrier begins to wear.

It's a very common thing.

Last edited by drew303; 07-31-2007 at 07:56 PM.

#32

Registered User

Join Date: Mar 2004

Location: Salem,Oregon

Posts: 511

Likes: 0

Received 0 Likes

on

0 Posts

The excessive carrier wear would be due to neglect in the oil department however the axle bearings will die with age so they are typically the area to fail first.

Seems like a whole third would be in order. If you managed to kill those side gears then I suspect that everything else is not far behind so a locker fix would only bring more repairs later.

I guess I have a hard time believing that the side gears failed before everything else???? The side gears probably receive the least amount of movement of any part of that diff. In a straight line they don't even have an wear they just spin at the same rate as the carrier!! I would expect to see Pinion bearings or gears wear out due to lack of carrier bearing pre-load long before I would expect to see a side gear fail from wear, excessive HP I can see but wear??.... I guess anything is possible

The verdict is that my Side Gears cannot be "adjusted" since they have worn themselves into the case. So a $$$$$$$$$$$$$600 quote was dished out to rebuild the 3rd member bearings and all.

I guess I have a hard time believing that the side gears failed before everything else???? The side gears probably receive the least amount of movement of any part of that diff. In a straight line they don't even have an wear they just spin at the same rate as the carrier!! I would expect to see Pinion bearings or gears wear out due to lack of carrier bearing pre-load long before I would expect to see a side gear fail from wear, excessive HP I can see but wear??.... I guess anything is possible

#33

Registered User

The excessive carrier wear would be due to neglect in the oil department however the axle bearings will die with age so they are typically the area to fail first.

Seems like a whole third would be in order. If you managed to kill those side gears then I suspect that everything else is not far behind so a locker fix would only bring more repairs later.

I guess I have a hard time believing that the side gears failed before everything else???? The side gears probably receive the least amount of movement of any part of that diff. In a straight line they don't even have an wear they just spin at the same rate as the carrier!! I would expect to see Pinion bearings or gears wear out due to lack of carrier bearing pre-load long before I would expect to see a side gear fail from wear, excessive HP I can see but wear??.... I guess anything is possible

Seems like a whole third would be in order. If you managed to kill those side gears then I suspect that everything else is not far behind so a locker fix would only bring more repairs later.

I guess I have a hard time believing that the side gears failed before everything else???? The side gears probably receive the least amount of movement of any part of that diff. In a straight line they don't even have an wear they just spin at the same rate as the carrier!! I would expect to see Pinion bearings or gears wear out due to lack of carrier bearing pre-load long before I would expect to see a side gear fail from wear, excessive HP I can see but wear??.... I guess anything is possible

I agree with you 100% on gear oil neglect. I bought my truck with 165k on it and the oil had never been changed and I know the kid before me had wheeled the piss out of it after having it handed down from his dad. Though the mechanic who diagnosed the problem said it was common in Chevys! =P

and my wheel bearings were shot at the same time, well I had figured wheel wobble WAS the bearings and they were shot, but it wasnt... the diagnosis of the carrier wear was about 4months after wheel bearing replacement. FYI.

#34

well, guys. I need to get a definite answer here. IS IT THE DIFF or IS IT NOT. I've talked to another mechanic who told me now that it might be the axle flange. No one ever answered me when i asked, should they be true with a straight edge or does it matter?

The only two things that can possibly be causing this is the third member as discussed, or the axle housing itself. Please help me out guys, your help is all greatly appreciated, and never overlooked.

and FYI, the PO did beat the out of it. and the oil when changed after 111000 miles was silver. metal shavings and wear galore. And the bearings, they are really shot hardcore too, so i am just as surprised as you are.

Things happen, and i just want it fixed. I'm 300 in, and i dont wanna spend a penny more than i have to. College student with a job he can't get to.

The only two things that can possibly be causing this is the third member as discussed, or the axle housing itself. Please help me out guys, your help is all greatly appreciated, and never overlooked.

and FYI, the PO did beat the out of it. and the oil when changed after 111000 miles was silver. metal shavings and wear galore. And the bearings, they are really shot hardcore too, so i am just as surprised as you are.

Things happen, and i just want it fixed. I'm 300 in, and i dont wanna spend a penny more than i have to. College student with a job he can't get to.

Last edited by Itoyota; 08-03-2007 at 09:55 PM.

#35

Contributing Member

My luck just keeps slipping downhill. Most of the yards around here won't sell the third member off any truck/4 runner. They'll go whole rear end for 200 and now that 1/2 the axle is new, i really don't wanna. man.

And if i changed the gear ratio. lets say from a 4.1 2 pinion 4cyl (stock) to a 4. x>1 ratio w/ 4 pinions that belong on a v6. Are we talking power loss? power gain? I know ring and pinion have a hella lot to do with torque. I have 31x11.5 that aren't on thanks to the gas prices, but would swapping up in pinion ratio 4.3 4.6 or swapping down be better?

And if i changed the gear ratio. lets say from a 4.1 2 pinion 4cyl (stock) to a 4. x>1 ratio w/ 4 pinions that belong on a v6. Are we talking power loss? power gain? I know ring and pinion have a hella lot to do with torque. I have 31x11.5 that aren't on thanks to the gas prices, but would swapping up in pinion ratio 4.3 4.6 or swapping down be better?

#36

Registered User

We can't see it (here, hold it closer to the monitor as you drive it so we can see it, and make sure you turn the sound up on your computer so that we can be sure to hear it) or hear it, and relying of pure observations from someone who is not a mechanic isn't going to do it

Since it's more than one thing that can be wrong, well there's the problem.

Sorry, but that's the fact of life.

You can "fix" something based on a recommendation here, but the odds are that the recommendation is a close to right as wrong since it could just as well be one of the other possibilities.

You're pretty much going to have to take it in and get it checked. The only way that you're going to be able to save money is to make sure you take it to someone who is qualified to diagnosis the problem.

Probably a diff. shop would be your best bet.

Not wanting to do that, they chances are pretty high, IMO, that you'll spend more than needed to get it fixed, basing your decision(s) on what to fixed on peoples opinion who are no where around the vehicle with multiple things that could cause the problem(s).

Fred

#37

Registered User

Fred nailed it

If you can find a private toyota specialist mechanic (like i have here in town whos been doin it 40 years) they will tell ya whats wrong

axle flange runout could be excessive, so could axle run out and the dif side gears could be shot, or the case worn etc... it could be all of that (as was for me) or just one thing...

a mechanic who knows how to check for all that will tell ya.

If you can find a private toyota specialist mechanic (like i have here in town whos been doin it 40 years) they will tell ya whats wrong

axle flange runout could be excessive, so could axle run out and the dif side gears could be shot, or the case worn etc... it could be all of that (as was for me) or just one thing...

a mechanic who knows how to check for all that will tell ya.

#38

well, i guess the only thing left is to check runout on the flange. The diff IS shot, period end of story. The side gears are worn into the casing. That's that. And i guess everyone keeps overlooking the simple question i keep asking.

Are the axle flange eyes supposed to be true to one another when checked with a straight edge. And thanks for stating the obvious and offering no NEW advice Senor FRED. The diff shop has been spoken with and as stated previously, it is " Impossible for a worn diff to cause wheel wobble at the ends of the axles" -Jim @ Driveline Specialists in Duluth MN

Drew. You replaced more than your diff, but if i recall correctly, after replacing/repairing it... The wobble quit.

Are the axle flange eyes supposed to be true to one another when checked with a straight edge. And thanks for stating the obvious and offering no NEW advice Senor FRED. The diff shop has been spoken with and as stated previously, it is " Impossible for a worn diff to cause wheel wobble at the ends of the axles" -Jim @ Driveline Specialists in Duluth MN

Drew. You replaced more than your diff, but if i recall correctly, after replacing/repairing it... The wobble quit.

#39

Registered User

well, i guess the only thing left is to check runout on the flange. The diff IS shot, period end of story. The side gears are worn into the casing. That's that. And i guess everyone keeps overlooking the simple question i keep asking.

Are the axle flange eyes supposed to be true to one another when checked with a straight edge. And thanks for stating the obvious and offering no NEW advice Senor FRED. The diff shop has been spoken with and as stated previously, it is " Impossible for a worn diff to cause wheel wobble at the ends of the axles" -Jim @ Driveline Specialists in Duluth MN

Drew. You replaced more than your diff, but if i recall correctly, after replacing/repairing it... The wobble quit.

Are the axle flange eyes supposed to be true to one another when checked with a straight edge. And thanks for stating the obvious and offering no NEW advice Senor FRED. The diff shop has been spoken with and as stated previously, it is " Impossible for a worn diff to cause wheel wobble at the ends of the axles" -Jim @ Driveline Specialists in Duluth MN

Drew. You replaced more than your diff, but if i recall correctly, after replacing/repairing it... The wobble quit.

Look man, we're all here offering free advice and experience. No reason to get hostile with folks.

Second of all, Jim @ driveline specialists is wrong.

and I'll repeat for the millionth time, wheel bearing replacement did not fix wheel wobble... Ok maybe i should explain it this way... Dont get axle runout and differential mixed up, they can produce the same wobble for entirely different reasons.

If the axle isnt secure in the dif (worn case) it pivots on the bearing, wobbles. (*tink tink tink) sound when you wiggle the wheel.

If you dont get any axle play but teh wheel still wobbles it's flange runout or axle runout, probably both.

The TWO can happen at the same time or one before the other or simulataneously or just one OR the other.

If you dont believe me that JIM at driveline tech (didnt know folks that make drivelines know everything about differentials

) take your third off, stick your axles in, bolt them up and move teh axle up n down...

) take your third off, stick your axles in, bolt them up and move teh axle up n down... then come back and explain to us how jim is right.

We know you are frustrated but the reality is these things break and wear out and need replacing. Toyotas are tough but not indestructible.

#40

okay, that made sense. And by no means am i getting hostile. Especially not with you. I deeply appreciate your help, and hope to soon accredit the fix to your advice.

I know Jim has got some skewed logic, and i guess it's just too much conflicting info.

Thnaks for all your help everyone, including fred, and If anyone cares to know. I'll either be posting the victory thread with a special thanks to drew, or another wild goose chase to find this death wobble.

I know Jim has got some skewed logic, and i guess it's just too much conflicting info.

Thnaks for all your help everyone, including fred, and If anyone cares to know. I'll either be posting the victory thread with a special thanks to drew, or another wild goose chase to find this death wobble.