Regular guy with regular tools gear swap (Lots of pics)

#1

Regular guy with regular tools gear swap (Lots of pics)

I am about to do a gear swap on my 91 pickup as cheap as possible with as basic of tools as possible. Bring on the neysayers! If you are brave enough.....follow me into the mists of Avalon! I am going from 4:10 to 4.88 as cheap as possible. I have never done this before but have done just about everything else. I hope this helps someone or at least shows them what not to do. Here is how much I have in it so far. This is just the rear 8" axle for now.

R&P $113.00

Master install kit $94.00

Gear oil $21.00

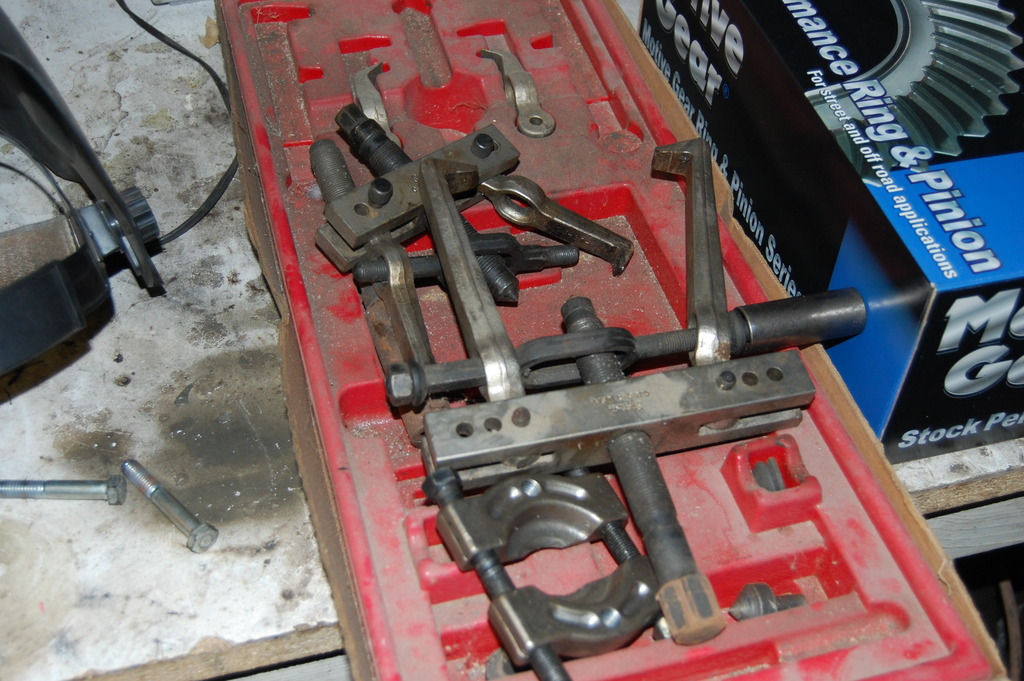

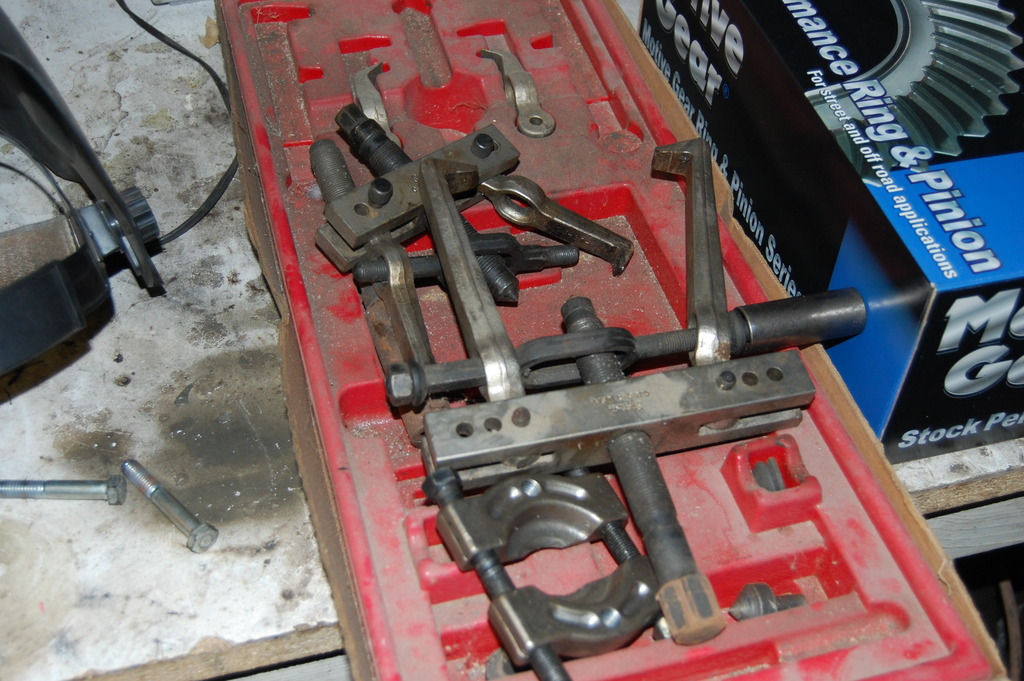

Borrowed puller from my friend.....priceless.

I have a press and calipers and a small machine shop in my basement so I will save some money by not having to buy some of those tools. If I mess it up and it blows my rear after the first 50 miles then I guess I get to do it again. I have shied away from this job for years because of mystique that surrounded it. I always thought that only old guys with thousands of dollars of tools and decades of experience could do this. I'm sure they are lights years better than I will be at this task.......but you have to start somewhere.

Here we go.

I pulled the axles.....I really like the removable 3rd member! Much easier than my jeep to work on.

Axles out!

Crusty Axle housing... This axle laid in my yard for 9 years before i used it.

3rd member out

Punched the bearing caps

My gear oil wasn't very old but it looked nasty!

Slimy Crush sleeve!

Carrier...

Crusty old 4.10's

New parts!

Borrowed pullers!

New Gears!

Driving out the old pinion bearing races with a 5/8 brass rod.

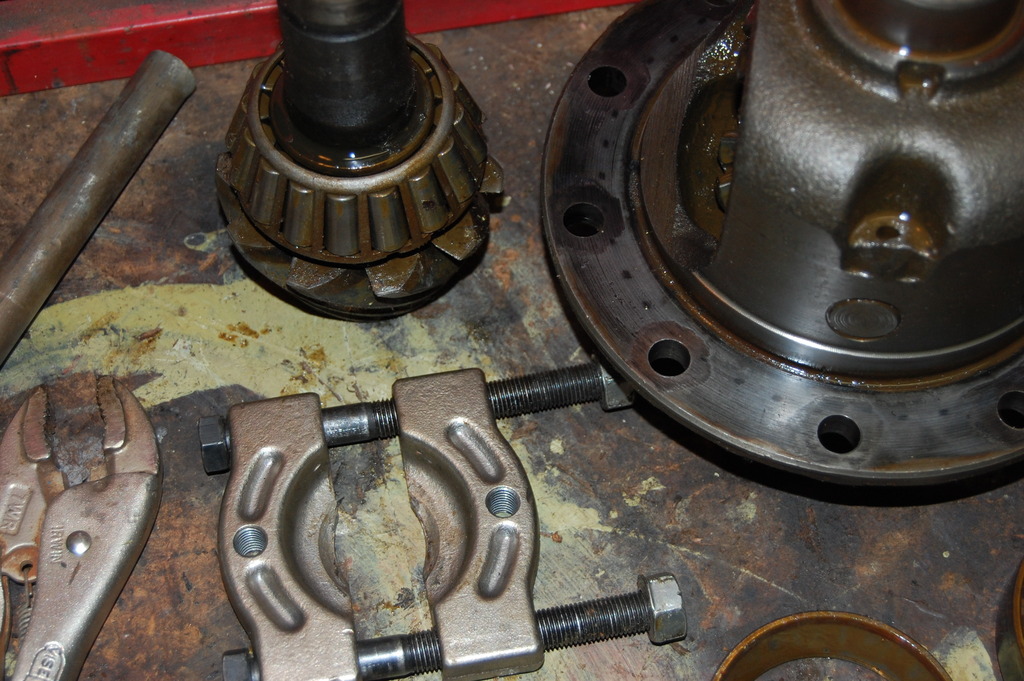

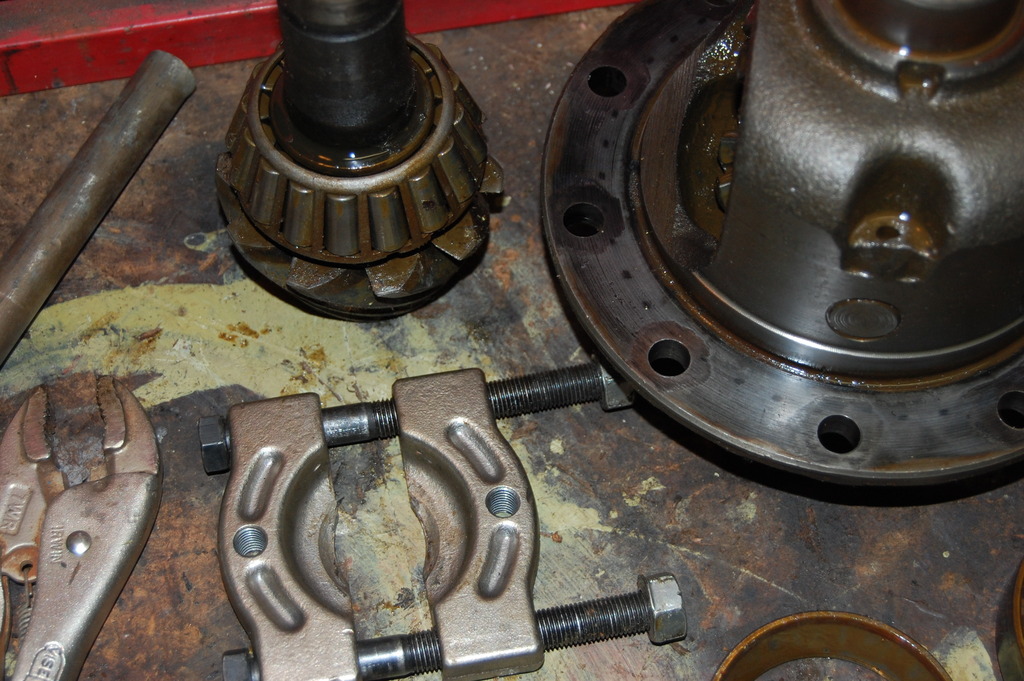

Pressing off the old pinion bearing so I can measure the old shim. (with my ancient homemade press)

Old shim was .089...

Slid it on the new pinion for fun.

R&P $113.00

Master install kit $94.00

Gear oil $21.00

Borrowed puller from my friend.....priceless.

I have a press and calipers and a small machine shop in my basement so I will save some money by not having to buy some of those tools. If I mess it up and it blows my rear after the first 50 miles then I guess I get to do it again. I have shied away from this job for years because of mystique that surrounded it. I always thought that only old guys with thousands of dollars of tools and decades of experience could do this. I'm sure they are lights years better than I will be at this task.......but you have to start somewhere.

Here we go.

I pulled the axles.....I really like the removable 3rd member! Much easier than my jeep to work on.

Axles out!

Crusty Axle housing... This axle laid in my yard for 9 years before i used it.

3rd member out

Punched the bearing caps

My gear oil wasn't very old but it looked nasty!

Slimy Crush sleeve!

Carrier...

Crusty old 4.10's

New parts!

Borrowed pullers!

New Gears!

Driving out the old pinion bearing races with a 5/8 brass rod.

Pressing off the old pinion bearing so I can measure the old shim. (with my ancient homemade press)

Old shim was .089...

Slid it on the new pinion for fun.

The following users liked this post:

karter9907 (09-07-2020)

Trending Topics

#12

...and it's generally ok to reuse the ring bolts too.

Are those Nitro Gears?

Last edited by ZUK; 03-04-2016 at 07:01 AM.

#13

I chucked them and just used the red locktite supplied with my install kit. It also came with new bolts. They are motive gears. Now my next issue is that the new crush sleeve in my install kit is .045 shorter than the old one!??

#16

Here is the install kit.

New bearings and ring gear installed.

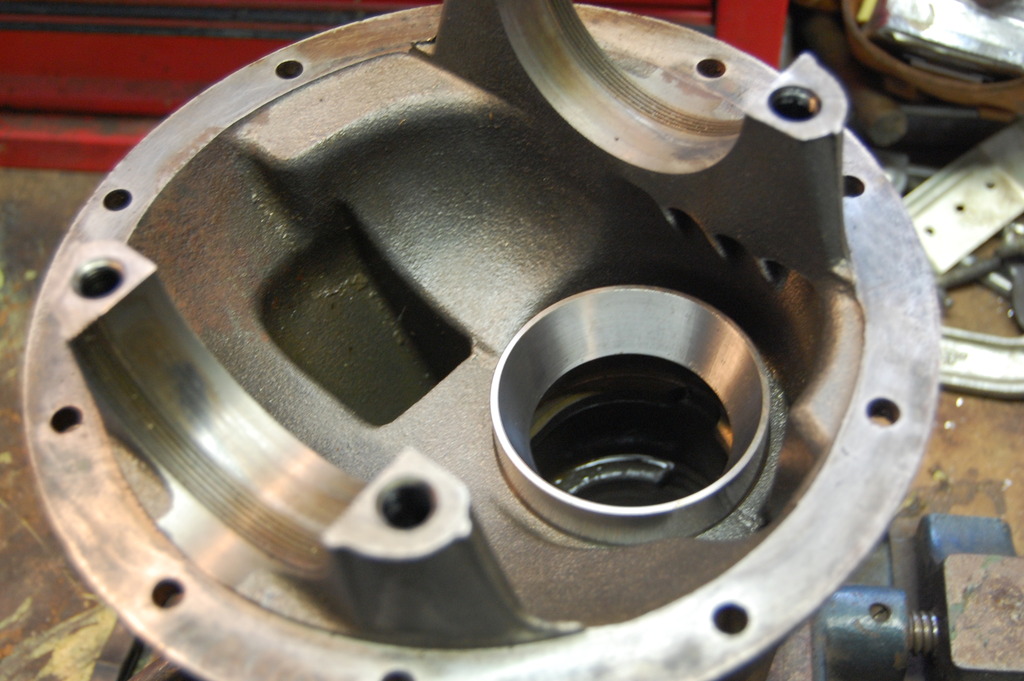

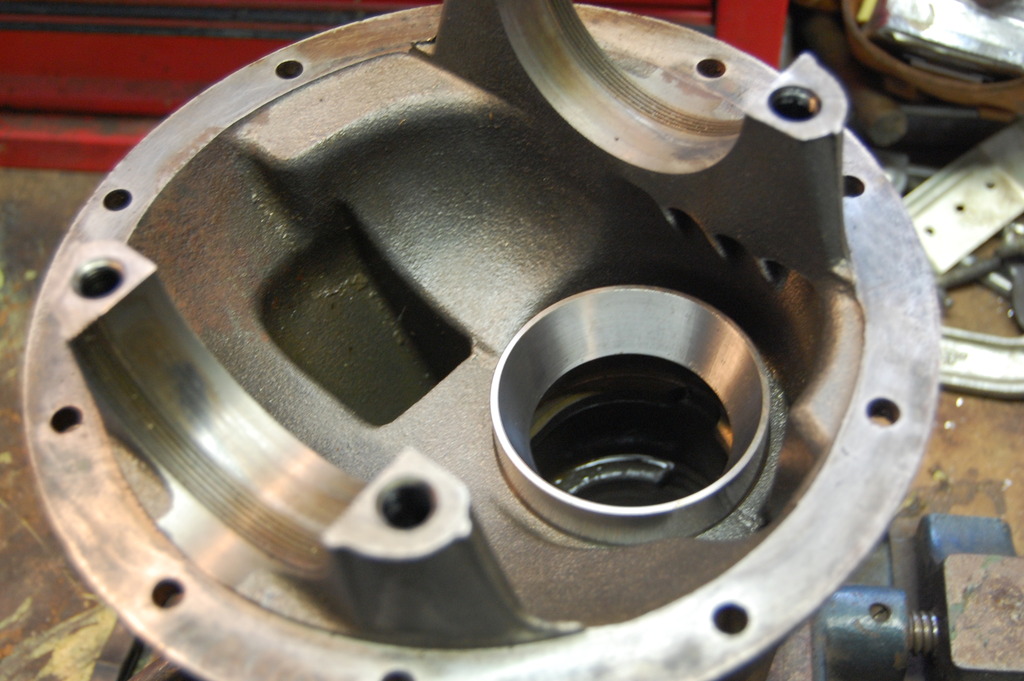

New races going in.

New bearing with old .089 shim

Pinion in...

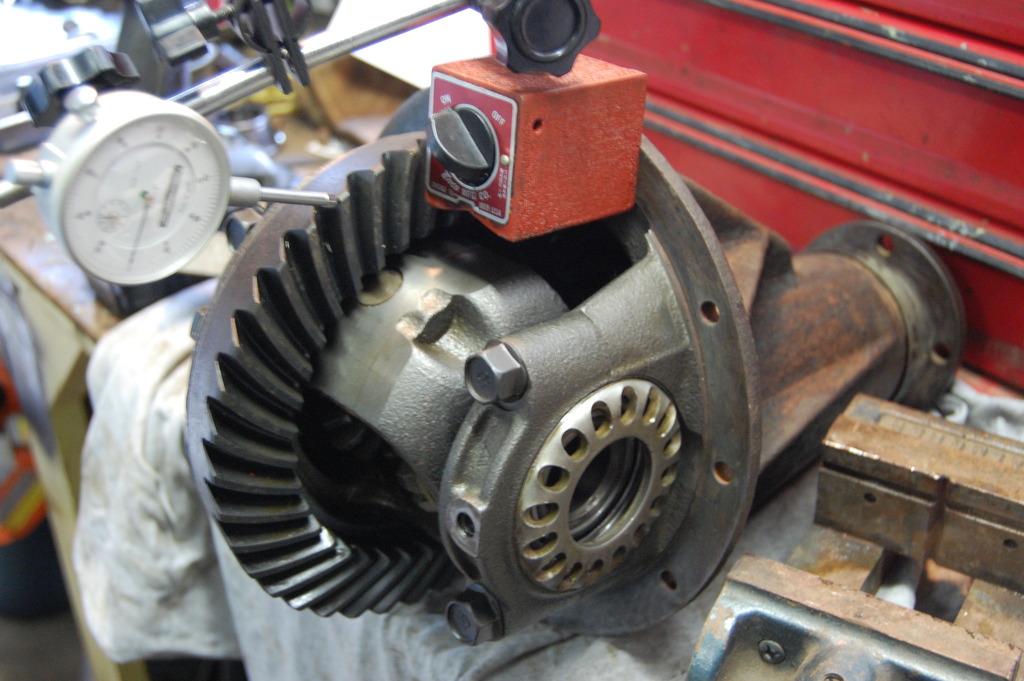

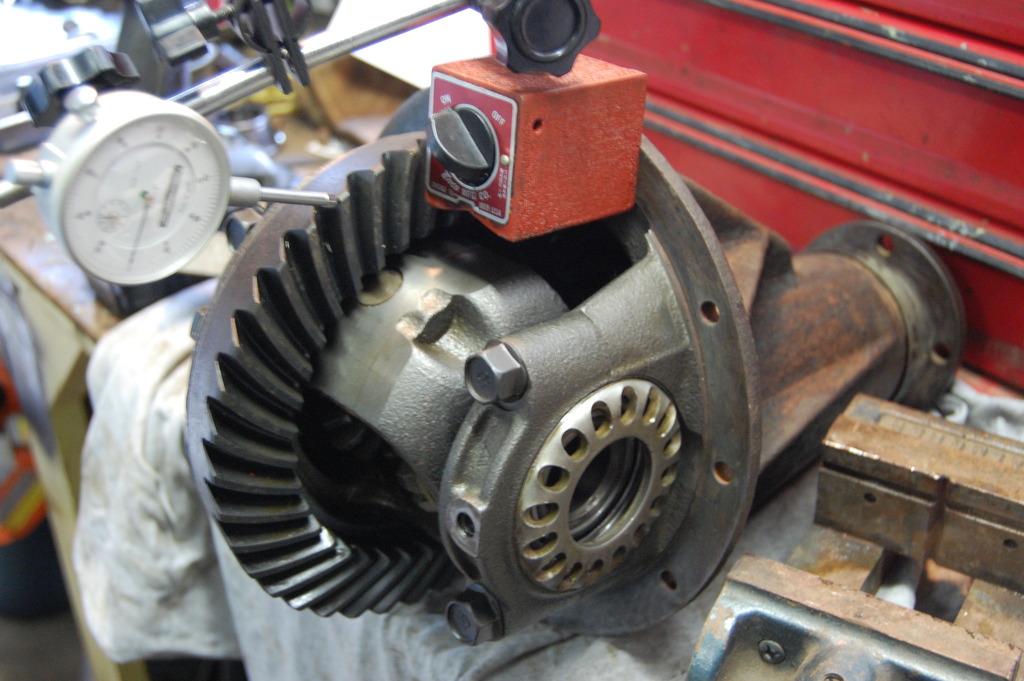

Checking backlash during temp install... I followed the instructions and set it to .008.

Custom adjuster tool

getting ready to check

Something is way off..... Pinion doesn't rotate smoothly and makes a little tapping sound when rotating. What do you think is going on?

New bearings and ring gear installed.

New races going in.

New bearing with old .089 shim

Pinion in...

Checking backlash during temp install... I followed the instructions and set it to .008.

Custom adjuster tool

getting ready to check

Something is way off..... Pinion doesn't rotate smoothly and makes a little tapping sound when rotating. What do you think is going on?

#17

OK....first off, there is only 1 size of new crush sleeve for all the 8" 4 cylinders....doesn't make any diff if your 3rd is from an early 79~85 truck or even the 86 thru 95 trucks.....same uncrush length which has always been 2.510" or very close. So they threw the wrong crush in your kit.

If you wanted to get it together quickly then add a .010" shim to the old one and use it(assuming your have the right shims to fit). Nothing catastrophic happens by doing so. It's a good emergency fix.

Your pattern ....a common issue...B kit bearing and a short pinion head.

Change your shim to about .235" and then post a pic.

ps----Nice simple adjuster wheel tool you have there.

If you wanted to get it together quickly then add a .010" shim to the old one and use it(assuming your have the right shims to fit). Nothing catastrophic happens by doing so. It's a good emergency fix.

Your pattern ....a common issue...B kit bearing and a short pinion head.

Change your shim to about .235" and then post a pic.

ps----Nice simple adjuster wheel tool you have there.

Last edited by ZUK; 03-04-2016 at 11:49 AM.

#18

Zuk, thank you for all the advice.... it is appreciated. I looked at my install kit box it is labeled 86+ toyota 8" 4cyl. so I guess I got the wrong one. So you think it will be close if I just add a shim to the old sleeve?

Just so we are on the same page.....to correct my patter i need to up my pinion shim from .089 to .235? Thanks again!

Just so we are on the same page.....to correct my patter i need to up my pinion shim from .089 to .235? Thanks again!

#19

yes, up it from 089 to 235

Well...not really the wrong kit where it is unusable. That kit will work just fine with a .235" shim. But they plain ole screwed up with the crush on their end. Ya, add a .010 or larger shim to the crush and that will fix it so you can use the new shiny one....but I suspect you will not have a good one with the right ID and OD.

Well...not really the wrong kit where it is unusable. That kit will work just fine with a .235" shim. But they plain ole screwed up with the crush on their end. Ya, add a .010 or larger shim to the crush and that will fix it so you can use the new shiny one....but I suspect you will not have a good one with the right ID and OD.

#20

Yeah the rest of the kit seems right so thats good. Ok I will add the pinion shims and post pics of the pattern..... I should be able to find a small shim for the sleeve. I have also heard of people sliding them over a pipe and hitting it on the bulge to lengthen it.