my 3.4 swap + T-100 auto into 89 4x4

#1

my 3.4 swap + T-100 auto into 89 4x4

This is an older thread that I had on another website for my build, it looks like there isnt much on this website for the auto swaps either, so here is one that I havent seen on another truck yet, hope you guys like it and hope it is useful to someone thinking about doing the swap......JUST DO IT AND DONT LOOK BACK!!!!

Here is what I am doing right now to make my truck good, My 89 pickup used to be a 5 speed 3.0 4x4, but now Its gonna be equipped with a 3.4 out of a 99 4 runner and an auto trans and wiring harness out of a 1995 T-100. Now you might ask, why such a wierd combo? Well, I dont have the money for the adapter to make a taco auto tranny fit my truck, but a T-100 has a right hand drop transfer case and a 3.4 from the factory. I got the engine and tranny straight across for my 3.slow, I used to work at a toyota junkyard when I started this, and the 3.0 out of my truck sold for more than the 3.4 is worth.

Here is a pic of the truck I took the engine out of.

here is a pic of the engine out of the truck

here is some pics of the 3.4 oil pan as compared to the 3.0 oil pan, you must re-use all 3.0 oil pan/pickup tube and baffle spacer plate.

The old front dipstick will have to go, I used a 1/4 inch pipe plug that is used for oil galleys on small block chevys, along with a dab of silicone.

Here is the devil :evil: This little nightmare took over 1 1/2 hours to get out of the T-100 block, you must use this little adapter and dipstick tube from the T-100.

here is the new oil pan on the new engine, note the motor mounts, they are direct bolt on's from the 3.0, all the way up to the block down to the rubber pads, the 3.4 ones were 100 percent wrong. Some guy told me they were the same and to just drop it in my truck, that would have sucked.

pass side motor mount

Here is a pic of the bad 3.4 out of the T-100, it ran but it smoked, I had to change everything off the T-100 engine to match the 4 runner engine, Injectors, knock sensors, middle and upper intake, every acessory on the engine was different from the 99-runner to the 95 T-100.

Here is the 3.4 T-100 Tranny and transfer case to get an idea of the size, It is actually only 1/2 inch longer than a stock 3.0 truck or runner auto.

since it is recommended, and I like body lifts because it is easier to work on, I went with the minimum of 2 inch body lift from performance accesories, half the bolts were the wrong length and the bumper brackets really suck, I wouldnt tell a friend to buy that brand.

This part was fun, that plate didnt fit at all, I had to "massage the firewall" to make it fit and silicone it up to make sure it was not gonna leak.

And here is the empty engine bay.

Nice and clean and sexy, I know, but I had to have the engine and tranny set in and out of the shop in 4 hours then tow it home like that :mad3: The owner of the shops wife is a bad lady and changed company policy right after the 3.slow came out. Said to get it out of the shop since it doesnt belong to the company, oh well.

Got the engine in the truck, took all of 10 minutes to lift it up with the cherry picker, lower it in and bolt up all 4 motor mount bolts to the frame, and probably 45 minutes to install the tranny from underneath with a tranny jack, arent lift racks magical?

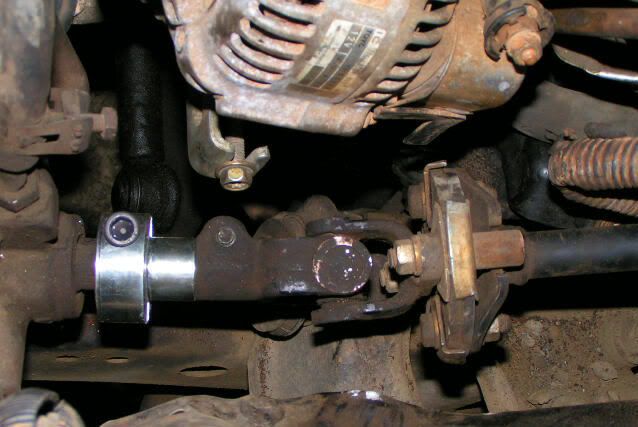

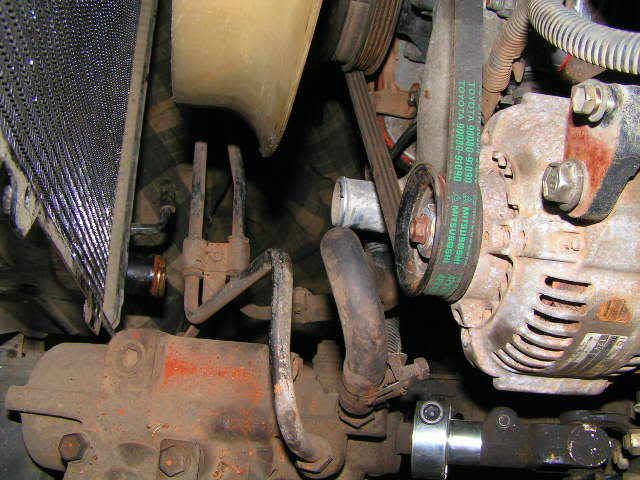

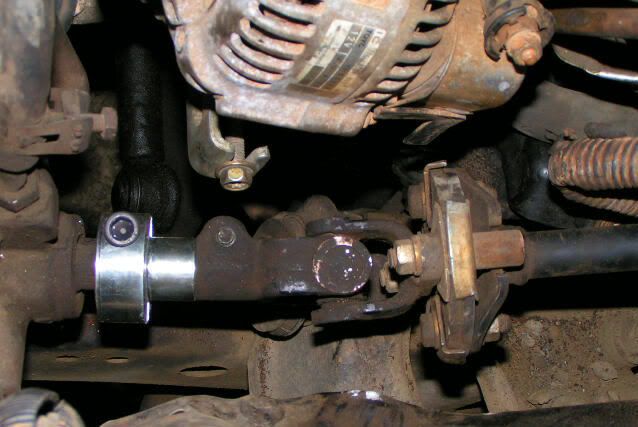

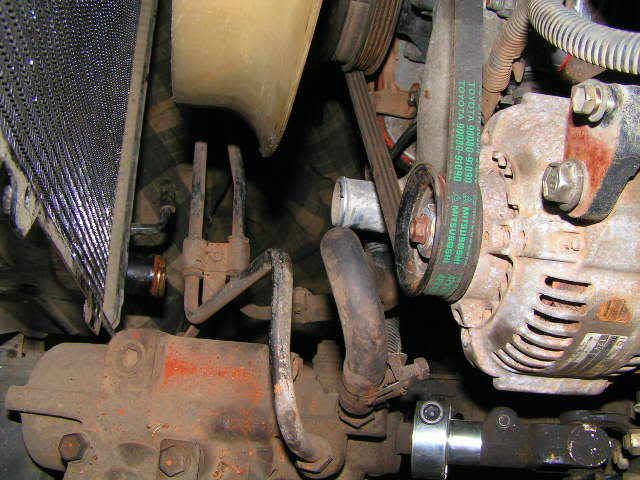

Notice the middle pic in the last post, the steering shaft rag joint actually hit the alternator, I tried a smaller belt, no go. The closest was 1 1/4 inches shorter and could not go on. The body lift also came with the rag joint spacer that just happened to make everything fit pretty good there.

It is very very tight at the driver side of the engine, it hits the passing gear cable and the dipstick is supposed to go there too. Maybe a aftermarket flexible dipstick tube from jegs or summit will fix that.

Here is some side shots of the engine in the truck.

The wiring harness went right into the firewall like the stock one, the taco and 4 runner have a odd shaped plate that mounts with two bolts, the T-100 has a regular old truck style push through.

I got a few small things done today, that whole life thing always slows down projects. I got the brake booster hooked up, the newer toyota's have a check valve on the booster itself, and my 89 has the valve in-line in the hose, so I bent the nipple on the booster straight so I could install the line and check valve and still have it look stock.

I also got the cruise control just about done, The V-6 cruise cable is very short, so I wandered around the junkyard and came up with this, the 4 cylinder fuel injected trucks have a very long cruise cable. I was going to swap out the entire cruise assembly but they actually look a little different and the parts all have different numbers on them and the 4 cyl unit is all black and my stock one is all gold anodized, the other would have plugged in if I stretched the wires, but I opted to just swap the cable off the 4 cyl unit, just easier and I know it will still work as it did with the old engine since the cruise is not controlled by the engine ecm, it has its own brain wired into the body harness.

Now for the sissy stuff also known as air conditioning. I really hope this helps someone else in the future. I tried a lot of stuff over the last three days and finally got the ac hooked up. The new 3.4 engine has a R-134A ac system, and all toyota's with this setup from 94 1/2 -present have bigger ac line fittings on both ends, evap and compressor ends. I thought, ok get the evap box out of a 95 pickup, its different a little but would work, ok. Nope, the lines coming out of the box to the condensor are wrong too, and if you took every part ouf of a 95 (the parts are 95 only) you could bolt the lines into the truck. I dont like having one year only wierd stuff on my trucks not to mention very expensive and of the several hundred toyotas at the junkyard, not one has a good condensor, basically if a yota isnt plowed in the front, then its not totalled enough and a gypsie car dealer will out bid you at the auto auction.

Here is the pics of the 3.0 bracket compared to the 3.4 bracket, the 3.0 has v-belt pulley.

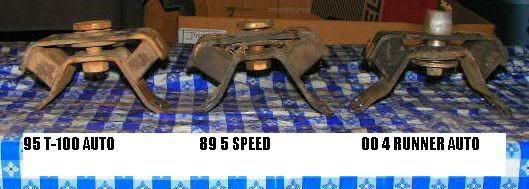

also here is the different style of compressors, the 89 3.0 comp is far left, the 92 3.0 comp is in the middle, the 95 3.4 is far right.

I did some looking and was told to use the stock 3.0 ac comp on the stock 3.0 bracket on the 3.4, it would have fit like crap and you have to change the ac clutch off the 3.4 comp to the old 3.0 one. I broke three ac compressors trying to do this, if the clutch doesnt come off with a tug, then it isnt coming off, is should just slide off.......ask me how I know. To get the first part of the clutch off I did this, take out 10 mm bolt, thread another toyota bolt with a 12 mm head into the threads in the clutch and thread in and it slides right off.

then remove the snap ring and slide the rest off. All three compressors seemed to bolt right up to the 3.4 bracket, not sure if the length would have been an issue or not, since I came up with something better using my man sized brain :laughing: Looking at the compressors on the bench I thought, man the intake/exhaust manifold on the compressors look very similar except where the hoses bolt up.

Guess what.

That sumbitch went right on from the old compressor to the new one, and all my old lines bolted right up, so not only do I have a R-134 friendly compressor, it is still a common part off a T-100. Its been holding for 2 days now, still has pressure, I am pretty happy how it came out.

Also got the power steering lines all hooked up to the T-100 3.4 pump, the low pressure side was no big deal, cut, bend to your liking, easy. The pressure side, I came up with this. The 89 hose has a thinner fitting on the end so the 3.4 bolt that holds the banjo fitting on is too long. I used a 3.0 pump banjo bolt and it seems to be working fine, I massaged the hardline a little where it comes out of the compressor just to make it fit a little better (I am a little anal on small details)

So far the only issue (I thought) is losing the steering idle up valve, I left this off and even on the 33's, it turns super easy on dry pavement with no stumbling even in drive at 500 rpms. That just goes to show you how much better the 3.4 is for power. The old v6 has this on the compressor, the 3.4 has it on the banjo fitting, and taco trucks and runners have rack and pinion, so no taking a line out of those and slapping it in the truck, and the T-100 is about a foot and a half wider so the hardline is wider and wont fit.

Got the air filter system installed today, this K&N setup came off a 97 tacoma that was rolled, it seems to fit pretty well, the T-100 air box was huge, I dont think it would have even fit under the hood in the right spot.

I also got the ignitor installed in the same spot as the T-100 had it, and it bolted up to some holes that were already there

I adjusted the cruise control bracket a little, because at the stock spot, the old style cable was adjusted as tight as it could get and still had slack, if this works I will make it better, if not I will figure out something else.

Also picked up a floor shifter for the auto, this one is out of a 2003 tacoma pickup, looks like it will fit perfectly where the stick used to be, my console even attaches to the back of it in the right spot.

I picked up a few transfer case shifters also, and since the new toyota trucks have a manual shifter lever for the transfer case, I dont need one of those ugly factory transfer case shifters, I mean, hell, the tranny shifter is ugly enough, toyota never made a good looking floor shifter for the auto......ever, at least not in any truck/suv I have seen.

Turns out the stock 89 shifter for the transfer case fit awesome, I just turned it 180 degrees and put it in this tranny, and it comes up through the Taco shifter assembly right where it should, fits good even with body lift and most importantly, it does not interfere with the shifter at all and my leg wont hit it either.

Got the radiator installed last night. The lower hose inlet/thermostat housing off the 3.4 did not like my old chassis layout and radiator. I tried the 99 4 runner lower hose, 97 tacoma lower hose and the 95 t-100 lower hose, and they all hit the power steering lines very badly. I used the 3.0 thermostat housing and stock hose and that worked good. Here is a pic of the 3.4 housing.

I used the stock 3.0 fan with the 3.4 clutch. The fan and clutch off either should fit but the 3.4 clutch is about 1/2 inch thicker in the middle bearing area, should be heavier duty. I would have used a taco fan blade but I couldnt find a good used one. I used the stock 3.0 fan shroud, and I used the stock upper hose off a 99 4-runner.

Got the fuel lines done, I used the stock 89 lower line, I cut the banjo fitting off the end and used the t-100 flare fitting and made a new end for the line.

I clamped the hose to the firewall where the brake booster hose used to be.

I modified the stock return metal hose and looped it behind the engine, and hooked it up to the stock return line.

I got the heater hoses all done, I used one stock tacoma heater hose for one side, and Used half the stock hose, spliced into half the other tacoma hose for the other side. As far as I know, off road specialists are the only people making hoses for this swap, unless you go this route. (I have 600 miles on this setup and still working great)

Also got the lower hose in, with the 3.o thermostat housing and hose.

Also got the upper hose off the 99 4 runner on my stock v6 radiator, works good, been holding water for three days with no issues.

also got the tranny pan on finally. I tried to use a 99 4 runner tranny oil pan with a right hand dipstick because of the dipstick on the T-100 tranny hitting my steering shaft. That was a no-go, it hits right where the driveshaft goes along the pan. If you had a sas truck with maybe 6 inches of lift?? that might work, but on compression of suspension on hard landings, it would still worry me.

I spent a few hours screwing around with the dipstick tube off the T-100, I ground off all the stock brackets, then put it in the truck, bent it a few times till it looked good, then fabbed up another bracket, it now bolts up to the manifold heat shield, I put a spacer on it so it would not be resting on the manifold directly.

I also spent a few hours screwing around with the passing gear bracket, You could probably just zip tie it to something, but thats where my adult A.D.D. kicks in, I gotta make it perfect or I am not happy. I cut the bracket, and bent it up about 1/2 and inch and welded it back up and bent with a BFH out of the truck and kept re-installing until I was happy. The end results are pretty good. Did I mention its tight under the hood of a toyota? :flipoff2:

And here is what my only child looks like when I am wrenchin' instead of taking her wheeling here she is sunday watching me work on her truck.

here she is sunday watching me work on her truck.

She has a rough life.

Also got my tranny cooler and lines completely done last night. A normal person could probably just run rubber hose from by the compressor where the hardlines end, but I want durability and dependability. Its been my experience that rubber lines will rub on stuff and fail.....eventually. I took the T-100 low pressure line for the power steering and lines for the stock tranny cooler and my tube bender and made some kick ass lines, this took several hours to do but I dont like getting the calls from the wife when the rig wont work right, I dont think anybody does.

I also added a large 8 pass aftermarket tranny cooler when I was in there, I am going to be running 33's on the truck again as soon as its back on the road again, and heat is a big killer of an auto tranny.

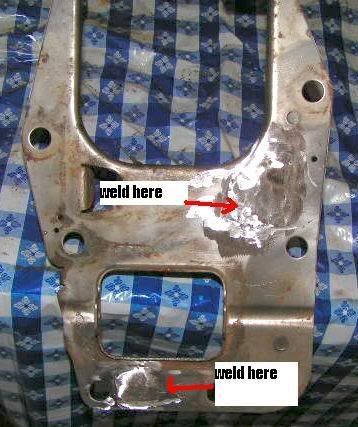

I got some work done on the shifter, Got a test fit, got some linkage, figured out what I needed to do then removed the shifter for a rebuild. First I modified the floor a little bit, I could have probably left it alone but it may have rubbed a hole in the shifter boot over time, we cant have that. Remember this is a newer taco shifter, a 4 runner should be the same shifter from 96-up because the old yota auto has a pass side shift linkage, new yota has driver side, as does the shifter.

marked the hole (orange silicone is from damage that was there when I bought truck, not sure what happened, didnt have body lift when I got it, they probably tried to remove tranny without pulling shifter first and cut floor)

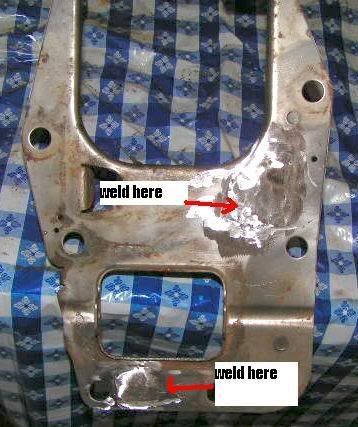

and the shifter plate fit pretty good, but there were two spots that were not covered by the floor, and I dont want water and air getting in so I welded up the holes with some sheetmetal I had laying around.

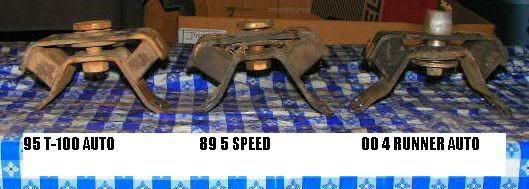

Also got the shifter working awesome, I tried a few different linkages, and a FYI I am pretty sure all T-100 trucks were column shift, I have 7 at the shop, all column shift. So I tried the T-100 shifter arm, wouldnt even shift at all, too much angle for the shifter to push it from the back (T-100 pulls from the front off a pivot) I also tried the 00 taco linkage, too long but could probably make it work. The best was the 99 4-runner shift linkage with the 4-runner shifter arm (I believe taco auto has the same arm). I had to slot the shift linkage a little to get all the gears where they should be on the shifter.

I will get more pics after I get the shifter back in the truck and the console figured out.

The shifter is in and done, all rebuilt and works and looks great, fits excellent, Here are some pics, and I used the front cover off the same 2003 tacoma that the shifter came out of, I just need to clean it up a little and paint it and cut my console a little so it fits better at the back of the new shifter cover, no big deal.

Here are a few different shifter covers I tried to use, but they all sucked and would not cover the shifter, it sits taller than the stock kind that would have been in an auto pickup or runner of this vintage.

I also got the crossmember done tonight, the damdest thing, I took an auto 92 4 runner crossmember home with the stock 89 v6 5-speed tranny mount and it fit the T-100 auto and the whole mess just bolted right in and worked great I was really worrying about this part, I thought it would be bad.

I was really worrying about this part, I thought it would be bad.

Here are some pics of how the crossmember sat with the stock 5 speed member and T-100 mount.

Also got the driveshafts in, great news here, I used the stock T-100 front shaft, bolted right in, and for the rear I used an 89 truck auto front half along with my stock 5 speed rear half, and went in with very little work. I had to slot the carrier bearing mount thats mounted on the frame, I added 1/2 inch towards the rear of the truck since this tranny is 1/2 inch longer than a stock 89 auto. The best part, its still all toyota, I can buy stock parts if I break something, and costs a hell of a lot less than buying custom shafts.

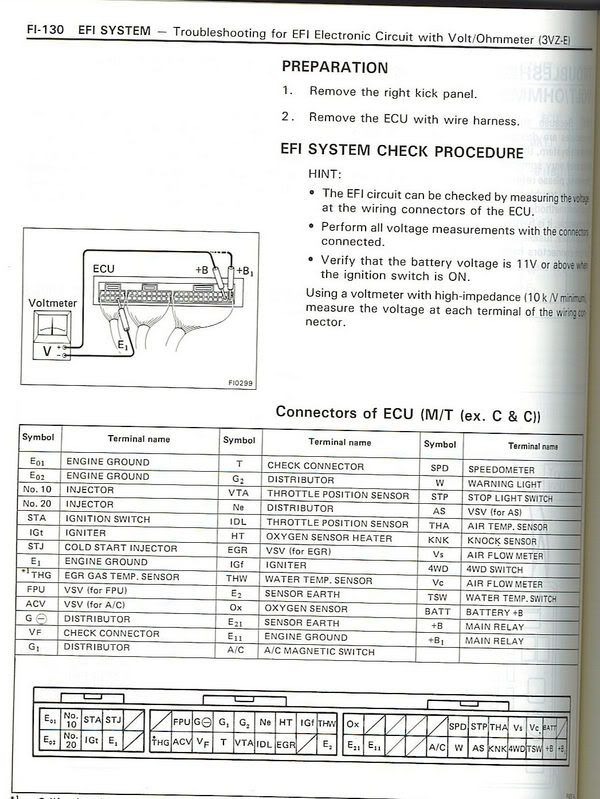

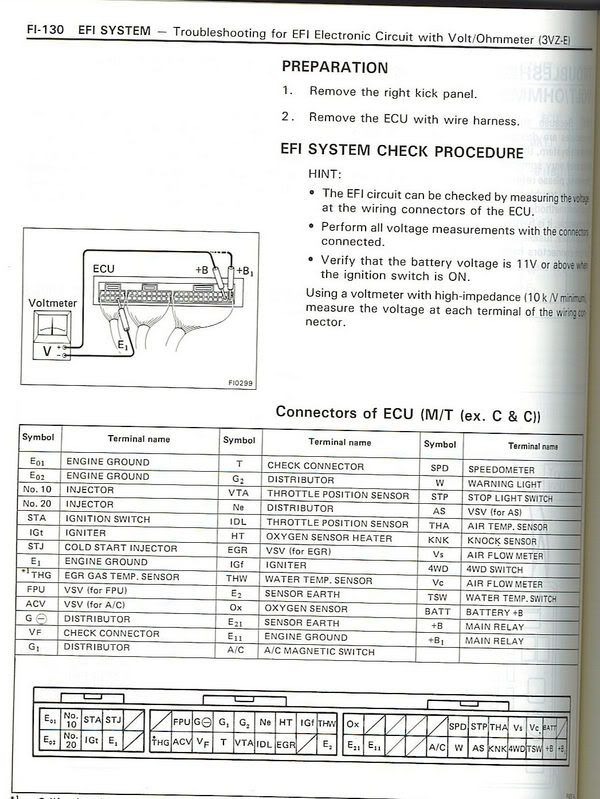

Got most of the wiring figured out, first thing I did was take the 89 factory toyota service manual off my shelf....noobs take note, that part is very important:flipoff2: and if you dont have one go here to buy one

http://techinfo.toyota.com/public/main/mdc.html

Here is where I started, with the 3.slow ecm and engine wiring on my bench...I mean kitchen table I got my factory manual and found a pic of my ecm and started labeling evey wire that I could, and the rest for the body plug I tracked down the old fashioned way and tagged all of them.

I got my factory manual and found a pic of my ecm and started labeling evey wire that I could, and the rest for the body plug I tracked down the old fashioned way and tagged all of them.

Here is what I did, I scanned a picture of the page I needed, printed it out, so I could take it outside, get it dirty, view it online, not have to drag the book everywhere I went.

I couldnt wait any longer for the T-100 fsm but I had the grey book, kind of hard to read if you have never read a wiring manual before, but a few hours a day of looking at it, and it made sense. I did the T-100 harness by hand (since I had not figured out how to read the wiring book yet), took a long time, but most of the wires are tagged now.

I spent more time doing wiring than any other part of the build, if it was not an auto it would be a hell of a lot easier, but I know what I want, and its going to be what I want. I am using the T-100 gauge cluster, making the gear indiactor work, all the dash lights and switches out of the T-100 auto and Taco shifter auto work like they came in the truck except for the terrible overdrive switch, I put it into the console in a spare switch hole and used a 4-runner window lock/unlock switch and painted over the lock letters, it needs to be wife-proof

Wiring is all done now, I had to add two more relays for the auto tranny stuff to wirk right like the backup lights and the neutral safety switch, I only had an issue with a wire on the tranny harness that happens to fit into two different sensors, kept causing the check engine light to come on. Here are some pics of my dash all done with the t-100 gauge cluster all done and the shifter indicator all working.

Here is the shifter all done and working awesome, the grey paint didnt match too well, I will go buy a new console cover from toyota as money permits. And shifter is all wired in, it only has one light bulb, nothing else.

For the battery tray I ordered a offroad specialists tray, could have been better, I spent about 4 hours making the battery tray to be what I considered safe. I used my angle finder to get the tray level, screwed the bottom side on, then welded the top part to the inner fender in two places, then I undercoated and painted the whole thing (I painted the underside before I installed it) then I screwed the stock plastic battery tray to the top of the new tray, I placed the screws where they would fit into ribs in the bottom of my battery so it could not slide around. I used one rod from the factory battery clamp and used ready rod for the other side, ran it through the battery tray and core support and bolted the bottom, then put on the new battery clamp.

Now for the crappy part.......exhaust. Originally I was told by my muffler shop to just put the engine in the truck and they were going to figure it out. Well, my new job is at a mechanic shop that is trying to merge into a full blown muffler shop as well. The boss wanted me to do the exhaust to learn how to use the bender since neither of us were very good (my first time) and he is smart so he makes me do the work and learnin stuff . Well here is what we came up with in two days and about 12 hours of labor and 25 feet of pipe.:eek: .

. Well here is what we came up with in two days and about 12 hours of labor and 25 feet of pipe.:eek: .

I wanted a single crossover pipe like off road specialists make, but I wanted to make it myself, but the boss was set on dual exhaust, until we figured how ˟˟˟˟ed it would be to run the rh pipe and then crossover under the truck somewhere, not happening. The headpipes are not my idea, I wanted to borrow another 3.4 from the junkyard and fab up the pipe and install, but you know how those old guys are stubborn :flipoff2: so this what we came up with. I did the back half myself, I ground off the old O2 sensor bungs and welded them onto the pipe and drilled the centers out, then got another set of oxygen sensor wiring off another t-100 and extended the harness so I would not have to cut mine and still get both hooked up. Boss also didnt want to run the cat, he said having no cat will not screw up the oxygen sensors, computer or running of the engine, I call bull˟˟˟˟˟ and I dont like the check engine light so I put the T-100 cat in my truck to keep it safe and also makes the flowmaster less honda like and gives it a deeper tone. And after driving on this for a month, it is not gonna stay in my truck, the pass side headpipe is rubbing on the head, and I think that is causing the check engine light for the knock sensor code. It only flashes the code when cold, before the pipe heats up and expands-pressing it tight against the head, so it rattles a little when cold making the sensors think there is a lot of ping so it sets the computer into safe loop mode (its a theory, but its all I got left)

I had a few questions from other people about the evap canister setup, and the t-100 has a metal round canister style evap that looks a lot like the old 89 one, it is just bigger around and taller and has an electronic controlled vacumn valve on it where the 89 was all mechanical. I cut up both the 89 bracket and the t-100 bracket and welded them up together and made a mount that fits in the factory location on the passenger side firewall and it works good. I have about 600 miles on the truck right now, been driving it to work and on the freeway, no problems except the knock sensor codes, and it actually pulls hills now and got my new 33's on it, cooper stt's and it still burns rubber even with those on there. The 4 wheel drive works great, 4 lo with the auto is ˟˟˟˟ing awesome, just crawls up the hills that my other chevy (not the one in the pic) on 36's with lockers screams up.

and got my new 33's on it, cooper stt's and it still burns rubber even with those on there. The 4 wheel drive works great, 4 lo with the auto is ˟˟˟˟ing awesome, just crawls up the hills that my other chevy (not the one in the pic) on 36's with lockers screams up.

Took this thing snow wheeling last weekend, worked awesome, great ground clearance with the tires and ifs, tons of power, pulled the mountain at 50 mph in third gear and barely working, my buddy in his 00 tacoma 4 cylinder 5-speed had his truck floored in third gear the whole way up the mountain and he is only running 31's. And the cooper stt's work awesome, they put the toyo open country mt's to shame, I want some 44 inch coopers for my chev, maybe some day.

Here is what I am doing right now to make my truck good, My 89 pickup used to be a 5 speed 3.0 4x4, but now Its gonna be equipped with a 3.4 out of a 99 4 runner and an auto trans and wiring harness out of a 1995 T-100. Now you might ask, why such a wierd combo? Well, I dont have the money for the adapter to make a taco auto tranny fit my truck, but a T-100 has a right hand drop transfer case and a 3.4 from the factory. I got the engine and tranny straight across for my 3.slow, I used to work at a toyota junkyard when I started this, and the 3.0 out of my truck sold for more than the 3.4 is worth.

Here is a pic of the truck I took the engine out of.

here is a pic of the engine out of the truck

here is some pics of the 3.4 oil pan as compared to the 3.0 oil pan, you must re-use all 3.0 oil pan/pickup tube and baffle spacer plate.

The old front dipstick will have to go, I used a 1/4 inch pipe plug that is used for oil galleys on small block chevys, along with a dab of silicone.

Here is the devil :evil: This little nightmare took over 1 1/2 hours to get out of the T-100 block, you must use this little adapter and dipstick tube from the T-100.

here is the new oil pan on the new engine, note the motor mounts, they are direct bolt on's from the 3.0, all the way up to the block down to the rubber pads, the 3.4 ones were 100 percent wrong. Some guy told me they were the same and to just drop it in my truck, that would have sucked.

pass side motor mount

Here is a pic of the bad 3.4 out of the T-100, it ran but it smoked, I had to change everything off the T-100 engine to match the 4 runner engine, Injectors, knock sensors, middle and upper intake, every acessory on the engine was different from the 99-runner to the 95 T-100.

Here is the 3.4 T-100 Tranny and transfer case to get an idea of the size, It is actually only 1/2 inch longer than a stock 3.0 truck or runner auto.

since it is recommended, and I like body lifts because it is easier to work on, I went with the minimum of 2 inch body lift from performance accesories, half the bolts were the wrong length and the bumper brackets really suck, I wouldnt tell a friend to buy that brand.

This part was fun, that plate didnt fit at all, I had to "massage the firewall" to make it fit and silicone it up to make sure it was not gonna leak.

And here is the empty engine bay.

Nice and clean and sexy, I know, but I had to have the engine and tranny set in and out of the shop in 4 hours then tow it home like that :mad3: The owner of the shops wife is a bad lady and changed company policy right after the 3.slow came out. Said to get it out of the shop since it doesnt belong to the company, oh well.

Got the engine in the truck, took all of 10 minutes to lift it up with the cherry picker, lower it in and bolt up all 4 motor mount bolts to the frame, and probably 45 minutes to install the tranny from underneath with a tranny jack, arent lift racks magical?

Notice the middle pic in the last post, the steering shaft rag joint actually hit the alternator, I tried a smaller belt, no go. The closest was 1 1/4 inches shorter and could not go on. The body lift also came with the rag joint spacer that just happened to make everything fit pretty good there.

It is very very tight at the driver side of the engine, it hits the passing gear cable and the dipstick is supposed to go there too. Maybe a aftermarket flexible dipstick tube from jegs or summit will fix that.

Here is some side shots of the engine in the truck.

The wiring harness went right into the firewall like the stock one, the taco and 4 runner have a odd shaped plate that mounts with two bolts, the T-100 has a regular old truck style push through.

I got a few small things done today, that whole life thing always slows down projects. I got the brake booster hooked up, the newer toyota's have a check valve on the booster itself, and my 89 has the valve in-line in the hose, so I bent the nipple on the booster straight so I could install the line and check valve and still have it look stock.

I also got the cruise control just about done, The V-6 cruise cable is very short, so I wandered around the junkyard and came up with this, the 4 cylinder fuel injected trucks have a very long cruise cable. I was going to swap out the entire cruise assembly but they actually look a little different and the parts all have different numbers on them and the 4 cyl unit is all black and my stock one is all gold anodized, the other would have plugged in if I stretched the wires, but I opted to just swap the cable off the 4 cyl unit, just easier and I know it will still work as it did with the old engine since the cruise is not controlled by the engine ecm, it has its own brain wired into the body harness.

Now for the sissy stuff also known as air conditioning. I really hope this helps someone else in the future. I tried a lot of stuff over the last three days and finally got the ac hooked up. The new 3.4 engine has a R-134A ac system, and all toyota's with this setup from 94 1/2 -present have bigger ac line fittings on both ends, evap and compressor ends. I thought, ok get the evap box out of a 95 pickup, its different a little but would work, ok. Nope, the lines coming out of the box to the condensor are wrong too, and if you took every part ouf of a 95 (the parts are 95 only) you could bolt the lines into the truck. I dont like having one year only wierd stuff on my trucks not to mention very expensive and of the several hundred toyotas at the junkyard, not one has a good condensor, basically if a yota isnt plowed in the front, then its not totalled enough and a gypsie car dealer will out bid you at the auto auction.

Here is the pics of the 3.0 bracket compared to the 3.4 bracket, the 3.0 has v-belt pulley.

also here is the different style of compressors, the 89 3.0 comp is far left, the 92 3.0 comp is in the middle, the 95 3.4 is far right.

I did some looking and was told to use the stock 3.0 ac comp on the stock 3.0 bracket on the 3.4, it would have fit like crap and you have to change the ac clutch off the 3.4 comp to the old 3.0 one. I broke three ac compressors trying to do this, if the clutch doesnt come off with a tug, then it isnt coming off, is should just slide off.......ask me how I know. To get the first part of the clutch off I did this, take out 10 mm bolt, thread another toyota bolt with a 12 mm head into the threads in the clutch and thread in and it slides right off.

then remove the snap ring and slide the rest off. All three compressors seemed to bolt right up to the 3.4 bracket, not sure if the length would have been an issue or not, since I came up with something better using my man sized brain :laughing: Looking at the compressors on the bench I thought, man the intake/exhaust manifold on the compressors look very similar except where the hoses bolt up.

Guess what.

That sumbitch went right on from the old compressor to the new one, and all my old lines bolted right up, so not only do I have a R-134 friendly compressor, it is still a common part off a T-100. Its been holding for 2 days now, still has pressure, I am pretty happy how it came out.

Also got the power steering lines all hooked up to the T-100 3.4 pump, the low pressure side was no big deal, cut, bend to your liking, easy. The pressure side, I came up with this. The 89 hose has a thinner fitting on the end so the 3.4 bolt that holds the banjo fitting on is too long. I used a 3.0 pump banjo bolt and it seems to be working fine, I massaged the hardline a little where it comes out of the compressor just to make it fit a little better (I am a little anal on small details)

So far the only issue (I thought) is losing the steering idle up valve, I left this off and even on the 33's, it turns super easy on dry pavement with no stumbling even in drive at 500 rpms. That just goes to show you how much better the 3.4 is for power. The old v6 has this on the compressor, the 3.4 has it on the banjo fitting, and taco trucks and runners have rack and pinion, so no taking a line out of those and slapping it in the truck, and the T-100 is about a foot and a half wider so the hardline is wider and wont fit.

Got the air filter system installed today, this K&N setup came off a 97 tacoma that was rolled, it seems to fit pretty well, the T-100 air box was huge, I dont think it would have even fit under the hood in the right spot.

I also got the ignitor installed in the same spot as the T-100 had it, and it bolted up to some holes that were already there

I adjusted the cruise control bracket a little, because at the stock spot, the old style cable was adjusted as tight as it could get and still had slack, if this works I will make it better, if not I will figure out something else.

Also picked up a floor shifter for the auto, this one is out of a 2003 tacoma pickup, looks like it will fit perfectly where the stick used to be, my console even attaches to the back of it in the right spot.

I picked up a few transfer case shifters also, and since the new toyota trucks have a manual shifter lever for the transfer case, I dont need one of those ugly factory transfer case shifters, I mean, hell, the tranny shifter is ugly enough, toyota never made a good looking floor shifter for the auto......ever, at least not in any truck/suv I have seen.

Turns out the stock 89 shifter for the transfer case fit awesome, I just turned it 180 degrees and put it in this tranny, and it comes up through the Taco shifter assembly right where it should, fits good even with body lift and most importantly, it does not interfere with the shifter at all and my leg wont hit it either.

Got the radiator installed last night. The lower hose inlet/thermostat housing off the 3.4 did not like my old chassis layout and radiator. I tried the 99 4 runner lower hose, 97 tacoma lower hose and the 95 t-100 lower hose, and they all hit the power steering lines very badly. I used the 3.0 thermostat housing and stock hose and that worked good. Here is a pic of the 3.4 housing.

I used the stock 3.0 fan with the 3.4 clutch. The fan and clutch off either should fit but the 3.4 clutch is about 1/2 inch thicker in the middle bearing area, should be heavier duty. I would have used a taco fan blade but I couldnt find a good used one. I used the stock 3.0 fan shroud, and I used the stock upper hose off a 99 4-runner.

Got the fuel lines done, I used the stock 89 lower line, I cut the banjo fitting off the end and used the t-100 flare fitting and made a new end for the line.

I clamped the hose to the firewall where the brake booster hose used to be.

I modified the stock return metal hose and looped it behind the engine, and hooked it up to the stock return line.

I got the heater hoses all done, I used one stock tacoma heater hose for one side, and Used half the stock hose, spliced into half the other tacoma hose for the other side. As far as I know, off road specialists are the only people making hoses for this swap, unless you go this route. (I have 600 miles on this setup and still working great)

Also got the lower hose in, with the 3.o thermostat housing and hose.

Also got the upper hose off the 99 4 runner on my stock v6 radiator, works good, been holding water for three days with no issues.

also got the tranny pan on finally. I tried to use a 99 4 runner tranny oil pan with a right hand dipstick because of the dipstick on the T-100 tranny hitting my steering shaft. That was a no-go, it hits right where the driveshaft goes along the pan. If you had a sas truck with maybe 6 inches of lift?? that might work, but on compression of suspension on hard landings, it would still worry me.

I spent a few hours screwing around with the dipstick tube off the T-100, I ground off all the stock brackets, then put it in the truck, bent it a few times till it looked good, then fabbed up another bracket, it now bolts up to the manifold heat shield, I put a spacer on it so it would not be resting on the manifold directly.

I also spent a few hours screwing around with the passing gear bracket, You could probably just zip tie it to something, but thats where my adult A.D.D. kicks in, I gotta make it perfect or I am not happy. I cut the bracket, and bent it up about 1/2 and inch and welded it back up and bent with a BFH out of the truck and kept re-installing until I was happy. The end results are pretty good. Did I mention its tight under the hood of a toyota? :flipoff2:

And here is what my only child looks like when I am wrenchin' instead of taking her wheeling

here she is sunday watching me work on her truck.

here she is sunday watching me work on her truck.

She has a rough life.

Also got my tranny cooler and lines completely done last night. A normal person could probably just run rubber hose from by the compressor where the hardlines end, but I want durability and dependability. Its been my experience that rubber lines will rub on stuff and fail.....eventually. I took the T-100 low pressure line for the power steering and lines for the stock tranny cooler and my tube bender and made some kick ass lines, this took several hours to do but I dont like getting the calls from the wife when the rig wont work right, I dont think anybody does.

I also added a large 8 pass aftermarket tranny cooler when I was in there, I am going to be running 33's on the truck again as soon as its back on the road again, and heat is a big killer of an auto tranny.

I got some work done on the shifter, Got a test fit, got some linkage, figured out what I needed to do then removed the shifter for a rebuild. First I modified the floor a little bit, I could have probably left it alone but it may have rubbed a hole in the shifter boot over time, we cant have that. Remember this is a newer taco shifter, a 4 runner should be the same shifter from 96-up because the old yota auto has a pass side shift linkage, new yota has driver side, as does the shifter.

marked the hole (orange silicone is from damage that was there when I bought truck, not sure what happened, didnt have body lift when I got it, they probably tried to remove tranny without pulling shifter first and cut floor)

and the shifter plate fit pretty good, but there were two spots that were not covered by the floor, and I dont want water and air getting in so I welded up the holes with some sheetmetal I had laying around.

Also got the shifter working awesome, I tried a few different linkages, and a FYI I am pretty sure all T-100 trucks were column shift, I have 7 at the shop, all column shift. So I tried the T-100 shifter arm, wouldnt even shift at all, too much angle for the shifter to push it from the back (T-100 pulls from the front off a pivot) I also tried the 00 taco linkage, too long but could probably make it work. The best was the 99 4-runner shift linkage with the 4-runner shifter arm (I believe taco auto has the same arm). I had to slot the shift linkage a little to get all the gears where they should be on the shifter.

I will get more pics after I get the shifter back in the truck and the console figured out.

The shifter is in and done, all rebuilt and works and looks great, fits excellent, Here are some pics, and I used the front cover off the same 2003 tacoma that the shifter came out of, I just need to clean it up a little and paint it and cut my console a little so it fits better at the back of the new shifter cover, no big deal.

Here are a few different shifter covers I tried to use, but they all sucked and would not cover the shifter, it sits taller than the stock kind that would have been in an auto pickup or runner of this vintage.

I also got the crossmember done tonight, the damdest thing, I took an auto 92 4 runner crossmember home with the stock 89 v6 5-speed tranny mount and it fit the T-100 auto and the whole mess just bolted right in and worked great

I was really worrying about this part, I thought it would be bad.

I was really worrying about this part, I thought it would be bad.

Here are some pics of how the crossmember sat with the stock 5 speed member and T-100 mount.

Also got the driveshafts in, great news here, I used the stock T-100 front shaft, bolted right in, and for the rear I used an 89 truck auto front half along with my stock 5 speed rear half, and went in with very little work. I had to slot the carrier bearing mount thats mounted on the frame, I added 1/2 inch towards the rear of the truck since this tranny is 1/2 inch longer than a stock 89 auto. The best part, its still all toyota, I can buy stock parts if I break something, and costs a hell of a lot less than buying custom shafts.

Got most of the wiring figured out, first thing I did was take the 89 factory toyota service manual off my shelf....noobs take note, that part is very important:flipoff2: and if you dont have one go here to buy one

http://techinfo.toyota.com/public/main/mdc.html

Here is where I started, with the 3.slow ecm and engine wiring on my bench...I mean kitchen table

I got my factory manual and found a pic of my ecm and started labeling evey wire that I could, and the rest for the body plug I tracked down the old fashioned way and tagged all of them.

I got my factory manual and found a pic of my ecm and started labeling evey wire that I could, and the rest for the body plug I tracked down the old fashioned way and tagged all of them.Here is what I did, I scanned a picture of the page I needed, printed it out, so I could take it outside, get it dirty, view it online, not have to drag the book everywhere I went.

I couldnt wait any longer for the T-100 fsm but I had the grey book, kind of hard to read if you have never read a wiring manual before, but a few hours a day of looking at it, and it made sense. I did the T-100 harness by hand (since I had not figured out how to read the wiring book yet), took a long time, but most of the wires are tagged now.

I spent more time doing wiring than any other part of the build, if it was not an auto it would be a hell of a lot easier, but I know what I want, and its going to be what I want. I am using the T-100 gauge cluster, making the gear indiactor work, all the dash lights and switches out of the T-100 auto and Taco shifter auto work like they came in the truck except for the terrible overdrive switch, I put it into the console in a spare switch hole and used a 4-runner window lock/unlock switch and painted over the lock letters, it needs to be wife-proof

Wiring is all done now, I had to add two more relays for the auto tranny stuff to wirk right like the backup lights and the neutral safety switch, I only had an issue with a wire on the tranny harness that happens to fit into two different sensors, kept causing the check engine light to come on. Here are some pics of my dash all done with the t-100 gauge cluster all done and the shifter indicator all working.

Here is the shifter all done and working awesome, the grey paint didnt match too well, I will go buy a new console cover from toyota as money permits. And shifter is all wired in, it only has one light bulb, nothing else.

For the battery tray I ordered a offroad specialists tray, could have been better, I spent about 4 hours making the battery tray to be what I considered safe. I used my angle finder to get the tray level, screwed the bottom side on, then welded the top part to the inner fender in two places, then I undercoated and painted the whole thing (I painted the underside before I installed it) then I screwed the stock plastic battery tray to the top of the new tray, I placed the screws where they would fit into ribs in the bottom of my battery so it could not slide around. I used one rod from the factory battery clamp and used ready rod for the other side, ran it through the battery tray and core support and bolted the bottom, then put on the new battery clamp.

Now for the crappy part.......exhaust. Originally I was told by my muffler shop to just put the engine in the truck and they were going to figure it out. Well, my new job is at a mechanic shop that is trying to merge into a full blown muffler shop as well. The boss wanted me to do the exhaust to learn how to use the bender since neither of us were very good (my first time) and he is smart so he makes me do the work and learnin stuff

. Well here is what we came up with in two days and about 12 hours of labor and 25 feet of pipe.:eek: .

. Well here is what we came up with in two days and about 12 hours of labor and 25 feet of pipe.:eek: .

I wanted a single crossover pipe like off road specialists make, but I wanted to make it myself, but the boss was set on dual exhaust, until we figured how ˟˟˟˟ed it would be to run the rh pipe and then crossover under the truck somewhere, not happening. The headpipes are not my idea, I wanted to borrow another 3.4 from the junkyard and fab up the pipe and install, but you know how those old guys are stubborn :flipoff2: so this what we came up with. I did the back half myself, I ground off the old O2 sensor bungs and welded them onto the pipe and drilled the centers out, then got another set of oxygen sensor wiring off another t-100 and extended the harness so I would not have to cut mine and still get both hooked up. Boss also didnt want to run the cat, he said having no cat will not screw up the oxygen sensors, computer or running of the engine, I call bull˟˟˟˟˟ and I dont like the check engine light so I put the T-100 cat in my truck to keep it safe and also makes the flowmaster less honda like and gives it a deeper tone. And after driving on this for a month, it is not gonna stay in my truck, the pass side headpipe is rubbing on the head, and I think that is causing the check engine light for the knock sensor code. It only flashes the code when cold, before the pipe heats up and expands-pressing it tight against the head, so it rattles a little when cold making the sensors think there is a lot of ping so it sets the computer into safe loop mode (its a theory, but its all I got left)

I had a few questions from other people about the evap canister setup, and the t-100 has a metal round canister style evap that looks a lot like the old 89 one, it is just bigger around and taller and has an electronic controlled vacumn valve on it where the 89 was all mechanical. I cut up both the 89 bracket and the t-100 bracket and welded them up together and made a mount that fits in the factory location on the passenger side firewall and it works good. I have about 600 miles on the truck right now, been driving it to work and on the freeway, no problems except the knock sensor codes, and it actually pulls hills now

and got my new 33's on it, cooper stt's and it still burns rubber even with those on there. The 4 wheel drive works great, 4 lo with the auto is ˟˟˟˟ing awesome, just crawls up the hills that my other chevy (not the one in the pic) on 36's with lockers screams up.

and got my new 33's on it, cooper stt's and it still burns rubber even with those on there. The 4 wheel drive works great, 4 lo with the auto is ˟˟˟˟ing awesome, just crawls up the hills that my other chevy (not the one in the pic) on 36's with lockers screams up.

Took this thing snow wheeling last weekend, worked awesome, great ground clearance with the tires and ifs, tons of power, pulled the mountain at 50 mph in third gear and barely working, my buddy in his 00 tacoma 4 cylinder 5-speed had his truck floored in third gear the whole way up the mountain and he is only running 31's. And the cooper stt's work awesome, they put the toyo open country mt's to shame, I want some 44 inch coopers for my chev, maybe some day.

Last edited by slater442w30; 01-15-2007 at 11:17 PM.

#6

In all honesty, too long. After the engine and tranny were set in and I towed it home, I had to lay on my back in the muddy gravel to finish the rest of the swap (except the exhaust) and I have never swapped any toyota or computer controlled engine before (I usually take the computers out of mid 80's gm cars I have owned) and the wiring took the longest, I estimate 200 hours of time into this project. I spent a few hours almost every day in the wrecking yard scouring for little parts and pieces and I hope my time will help other people to not waste so much time on their swap and not be so afraid to do it.

I am doing another right now for my ex boss, its a 1987 4-runner with the 5-speed and a trd turbo, I will try to get pics of that on here as I go, then I need to do the wifes 87 runner with the auto. I figure I will cut my time down by at least half now that I know more of what I am doing.

I am doing another right now for my ex boss, its a 1987 4-runner with the 5-speed and a trd turbo, I will try to get pics of that on here as I go, then I need to do the wifes 87 runner with the auto. I figure I will cut my time down by at least half now that I know more of what I am doing.

#7

The original console for 1989-1995 4cyl 4WD AT Trucks fits pretty good too:

http://www.4x4wire.com/toyota/tech/autocrawler/

http://www.4x4wire.com/toyota/tech/a...console_02.jpg

Mike @ ORS has those dip stick adapters:

http://www.4x4wire.com/toyota/tech/autocrawler/

http://www.4x4wire.com/toyota/tech/a...console_02.jpg

Mike @ ORS has those dip stick adapters:

Last edited by mt_goat; 01-16-2007 at 08:07 AM.

Trending Topics

#9

The original console for 1989-1995 4cyl 4WD AT Trucks fits pretty good too:

http://www.4x4wire.com/toyota/tech/autocrawler/

http://www.4x4wire.com/toyota/tech/a...console_02.jpg

Mike @ ORS has those dip stick adapters:

http://www.4x4wire.com/toyota/tech/autocrawler/

http://www.4x4wire.com/toyota/tech/a...console_02.jpg

Mike @ ORS has those dip stick adapters:

#10

im looking at getting a 95 T-100 donor vehicle to put its 3.4 into my 89 4runner. the wiring is the biggest part that scares me and $700 for a wire harness from ORS is NOT in the budget! what did you have to do with the wire harness to get it to work?

#11

You'll need the wiring diagrams from both FSMs for your donor engine/ECU, and the recipient truck. Then it will just be a case of hunt and peck to change your pin-outs to match everything up.

It is do-able, but I wouldn't recommend it if you are not VERY comfortable with wiring and electrical tasks! If you are not electrically inclined, you may find that the $700 would have been well spent.

Mike makes a very good product, and backs it up with help when you need it. I got his whole conversion kit mostly because of the time issues I had for my project, but I was very satisfied with the purchase, and it made the job a lot easier for me to deal with!

It is do-able, but I wouldn't recommend it if you are not VERY comfortable with wiring and electrical tasks! If you are not electrically inclined, you may find that the $700 would have been well spent.

Mike makes a very good product, and backs it up with help when you need it. I got his whole conversion kit mostly because of the time issues I had for my project, but I was very satisfied with the purchase, and it made the job a lot easier for me to deal with!

Thread

Thread Starter

Forum

Replies

Last Post