Help! head gasket job done, timing is another story..

#21

I'd still double check the valve clearance before I start tearing it down.

If a head gasket leak was your original problem it is not likely that it leaked across all 4 cylinders and damaged all 4. Now, you may have hydrolocked one and bent a rod, but that still would not show up as low compression on all 4.

If a head gasket leak was your original problem it is not likely that it leaked across all 4 cylinders and damaged all 4. Now, you may have hydrolocked one and bent a rod, but that still would not show up as low compression on all 4.

#22

im trying to track down some new rings. i can get teh rings for 50 bucks, i dont need to remove the timing cover to do this right? just pull the head, the oil pan, get the nuts off the bottom of the crank where the pistons are then pull them from the top of the block right? as long as i have the chain secured while the head is off i can do this without taking the front of the motor apart. that being said whats a good way to measure or check the clearance/okness of the bearings both the main and rod bearings?

and 1stgenboy, the shop didnt do a compression test but they are both toyota guys and said it would be totally fine. is there an easy way to check if the valves are ok?

I put the valves at .007 intake and .009 exhaust. i know the stock adjustment is .008 and .012 but todd over at engbldr said with my midrange cam i should adjust it at .007 and .009 they seem fine as far as adjustments go. i had just readjusted them before the head gasket blew out and after the shaving of the head and the work i JUST did, the valves werent very far off and didnt need much adjusting to get them back to where they should be so my guess is the rings and not the valves. im thinking the rings now because when i turned it on yesterday and tried to get it up my driveway it would die down as soon as i let the clutch up and die. totally powerless.. and if one ring failed due to excessive heat, dont you think all 4 would fail?

and 1stgenboy, the shop didnt do a compression test but they are both toyota guys and said it would be totally fine. is there an easy way to check if the valves are ok?

I put the valves at .007 intake and .009 exhaust. i know the stock adjustment is .008 and .012 but todd over at engbldr said with my midrange cam i should adjust it at .007 and .009 they seem fine as far as adjustments go. i had just readjusted them before the head gasket blew out and after the shaving of the head and the work i JUST did, the valves werent very far off and didnt need much adjusting to get them back to where they should be so my guess is the rings and not the valves. im thinking the rings now because when i turned it on yesterday and tried to get it up my driveway it would die down as soon as i let the clutch up and die. totally powerless.. and if one ring failed due to excessive heat, dont you think all 4 would fail?

#23

honestly this sounds like a timing problem to me,hows yor rotor fit in the distribitor....is it a tight fit or a sloppy fit.

i know my 82 had a sloppy fitting rotor,i couldnt get her timed right,kept bogging at low rpm,wouldnt idle.i put in a new rotor/cap....made a big difference,the new rotor fit tight,no slop.

what are the odds that your distribitor gear may have turned somehow?

something dont sound right.

if you had burnt rings,you would have low compression,possibly burning oil/smoky exhaust,and no power through the entire rpm range.

i know my 82 had a sloppy fitting rotor,i couldnt get her timed right,kept bogging at low rpm,wouldnt idle.i put in a new rotor/cap....made a big difference,the new rotor fit tight,no slop.

what are the odds that your distribitor gear may have turned somehow?

something dont sound right.

if you had burnt rings,you would have low compression,possibly burning oil/smoky exhaust,and no power through the entire rpm range.

Last edited by igotit; 08-15-2011 at 09:48 AM.

#24

Oh yeah...spring tension in the rings will be diminished from overheating. Still sounds like something else though. I have a 22R/20R Hybrid that I got so hot it dropped valve seats and made dings in the tops of the pistons. I had the head redone only and drove it from San Diego to Redmond Oregon. It idled rough, burnt oil, but had power in the upper rpm range.

If you put a tablespoon of oil in the cylinder and then do the compression test and the numbers go up significantly then you know it's the rings. That is as close as I know how to rule the valves in as the culprit...by elimating the rings.

Wish I could be of more help. It's been so long since I did this kind of work for a living that I make newbie mistakes on my own stuff. DOH

A couple of more things to check although I know you said you had low compression numbers. recheck your Firing order. And like another poster said, cap and rotor can cause wierd problems. I once had a friend scribble on the inside of my dizzy cap with a #2 pencil as a joke. It ran fine on the way home from his house, but when I came out from the house after a shower to go out for the night my car ran like ˟˟˟˟e.

If you put a tablespoon of oil in the cylinder and then do the compression test and the numbers go up significantly then you know it's the rings. That is as close as I know how to rule the valves in as the culprit...by elimating the rings.

Wish I could be of more help. It's been so long since I did this kind of work for a living that I make newbie mistakes on my own stuff. DOH

A couple of more things to check although I know you said you had low compression numbers. recheck your Firing order. And like another poster said, cap and rotor can cause wierd problems. I once had a friend scribble on the inside of my dizzy cap with a #2 pencil as a joke. It ran fine on the way home from his house, but when I came out from the house after a shower to go out for the night my car ran like ˟˟˟˟e.

im trying to track down some new rings. i can get teh rings for 50 bucks, i dont need to remove the timing cover to do this right? just pull the head, the oil pan, get the nuts off the bottom of the crank where the pistons are then pull them from the top of the block right? as long as i have the chain secured while the head is off i can do this without taking the front of the motor apart. that being said whats a good way to measure or check the clearance/okness of the bearings both the main and rod bearings?

and 1stgenboy, the shop didnt do a compression test but they are both toyota guys and said it would be totally fine. is there an easy way to check if the valves are ok?

I put the valves at .007 intake and .009 exhaust. i know the stock adjustment is .008 and .012 but todd over at engbldr said with my midrange cam i should adjust it at .007 and .009 they seem fine as far as adjustments go. i had just readjusted them before the head gasket blew out and after the shaving of the head and the work i JUST did, the valves werent very far off and didnt need much adjusting to get them back to where they should be so my guess is the rings and not the valves. im thinking the rings now because when i turned it on yesterday and tried to get it up my driveway it would die down as soon as i let the clutch up and die. totally powerless.. and if one ring failed due to excessive heat, dont you think all 4 would fail?

and 1stgenboy, the shop didnt do a compression test but they are both toyota guys and said it would be totally fine. is there an easy way to check if the valves are ok?

I put the valves at .007 intake and .009 exhaust. i know the stock adjustment is .008 and .012 but todd over at engbldr said with my midrange cam i should adjust it at .007 and .009 they seem fine as far as adjustments go. i had just readjusted them before the head gasket blew out and after the shaving of the head and the work i JUST did, the valves werent very far off and didnt need much adjusting to get them back to where they should be so my guess is the rings and not the valves. im thinking the rings now because when i turned it on yesterday and tried to get it up my driveway it would die down as soon as i let the clutch up and die. totally powerless.. and if one ring failed due to excessive heat, dont you think all 4 would fail?

#25

Thanks for the info guys! The cap/rotor are brand new as of a couple months ago and ive double checked everything looks great on the distributor. ive found the gear the dist. needs to be in(on the cam shaft gear) and moved it over 1 tooth counter clockwise and also tried one tooth over clockwise from the correct tooth, and it wouldnt run at all on the 2 other gears so im sure i have the distributor on the right tooth, and its timed correctly. Ill try a tablespoon of oil and see if that makes a difference with the compression test. the guys at the head shop visually inspected the valve assemblies and said they look fine, could something happen to the valves that would make them not work that you wouldnt be able to obviously notice?

I know the firing order is correct because it runs. lol no pinging or anything it just shakes like when your trying to tune a weber carb. it doesnt really smooth out when I rev it up either.

Any other ideas would be great before i tear it down, otherwise ill let you know how the compression test goes.

by the way there isnt any smoke of any kind out of the tail pipe, there is excessive moisture but the fluid levels are staying the same and im pretty sure its getting out the residual water from when i flooded the exhaust system with water from the blown motor. the plugs look white with black or dark brown residue around the tip(tip is white) so im still thinking rings.

I know the firing order is correct because it runs. lol no pinging or anything it just shakes like when your trying to tune a weber carb. it doesnt really smooth out when I rev it up either.

Any other ideas would be great before i tear it down, otherwise ill let you know how the compression test goes.

by the way there isnt any smoke of any kind out of the tail pipe, there is excessive moisture but the fluid levels are staying the same and im pretty sure its getting out the residual water from when i flooded the exhaust system with water from the blown motor. the plugs look white with black or dark brown residue around the tip(tip is white) so im still thinking rings.

#26

something else to check would be the catalytic converter,if after a 15 min run,if the converter is alot hotter than the muffler....then odds are its plugged up.

a blocked exhaust will not let spent air get out fast enough,bog it in idle and make it sluggish and slow acceleration.

just a thought.

a blocked exhaust will not let spent air get out fast enough,bog it in idle and make it sluggish and slow acceleration.

just a thought.

#27

igotit- I dont have a cat, its header, pipe, stock muffler that needs replacement, pipe..

Ok so here is the deal.. for whatever reason my valve adjustment wasnt right. i adjusted it cold when a mechanic buddy of mine said to do it hot. i did it hot and i set the valves to stock clearances(.008 intake and .012 exhaust) rather than the specs that todd at engbldr said to do for my 430/720(i could be wrong about that number its the midrange rv cam) which was .007 intake and .009 exhaust. what settings do you guys think i should choose?

Its timed at 8 degrees, but now i have to readjust my carb. i keep getting it to the baseline settings but i have to turn the mixture screw out more than 2 full rotations which tells me what that my jets are too small or too big? im lost there.. anyway ill tune it more later, ive got it to idle, drive, but when you get on it or want to go past 25 mph it backfires like a son of a gun out the tailpipe and out the carb.

I havent done a compression test yet to see what im getting there, i figured i would get the carb going right first.

I finally got my lesson on how VITAL it is to get your valve adjustment right. damn i never would have thought how sensetive those things could be.

Thanks for all your help guys you really got me through this BS.. Ill let you know how the carb tuning goes in the next few days. I have to finish a few illustrations before i can go back out there, clients are lining up lol.

I got my website up and running recently what do you guys think? www.chriswilhelmart.com

Ok so here is the deal.. for whatever reason my valve adjustment wasnt right. i adjusted it cold when a mechanic buddy of mine said to do it hot. i did it hot and i set the valves to stock clearances(.008 intake and .012 exhaust) rather than the specs that todd at engbldr said to do for my 430/720(i could be wrong about that number its the midrange rv cam) which was .007 intake and .009 exhaust. what settings do you guys think i should choose?

Its timed at 8 degrees, but now i have to readjust my carb. i keep getting it to the baseline settings but i have to turn the mixture screw out more than 2 full rotations which tells me what that my jets are too small or too big? im lost there.. anyway ill tune it more later, ive got it to idle, drive, but when you get on it or want to go past 25 mph it backfires like a son of a gun out the tailpipe and out the carb.

I havent done a compression test yet to see what im getting there, i figured i would get the carb going right first.

I finally got my lesson on how VITAL it is to get your valve adjustment right. damn i never would have thought how sensetive those things could be.

Thanks for all your help guys you really got me through this BS.. Ill let you know how the carb tuning goes in the next few days. I have to finish a few illustrations before i can go back out there, clients are lining up lol.

I got my website up and running recently what do you guys think? www.chriswilhelmart.com

#29

igotit- I dont have a cat, its header, pipe, stock muffler that needs replacement, pipe..

Ok so here is the deal.. for whatever reason my valve adjustment wasnt right. i adjusted it cold when a mechanic buddy of mine said to do it hot. i did it hot and i set the valves to stock clearances(.008 intake and .012 exhaust) rather than the specs that todd at engbldr said to do for my 430/720(i could be wrong about that number its the midrange rv cam) which was .007 intake and .009 exhaust. what settings do you guys think i should choose?

Ok so here is the deal.. for whatever reason my valve adjustment wasnt right. i adjusted it cold when a mechanic buddy of mine said to do it hot. i did it hot and i set the valves to stock clearances(.008 intake and .012 exhaust) rather than the specs that todd at engbldr said to do for my 430/720(i could be wrong about that number its the midrange rv cam) which was .007 intake and .009 exhaust. what settings do you guys think i should choose?

i

Its timed at 8 degrees, but now i have to readjust my carb. i keep getting it to the baseline settings but i have to turn the mixture screw out more than 2 full rotations which tells me what that my jets are too small or too big? im lost there.. anyway ill tune it more later, ive got it to idle, drive, but when you get on it or want to go past 25 mph it backfires like a son of a gun out the tailpipe and out the carb.

Its timed at 8 degrees, but now i have to readjust my carb. i keep getting it to the baseline settings but i have to turn the mixture screw out more than 2 full rotations which tells me what that my jets are too small or too big? im lost there.. anyway ill tune it more later, ive got it to idle, drive, but when you get on it or want to go past 25 mph it backfires like a son of a gun out the tailpipe and out the carb.

If your compression is not right, you will not get the carb to feel like it is in tune. basics first.

I finally got my lesson on how VITAL it is to get your valve adjustment right. damn i never would have thought how sensetive those things could be.

Thanks for all your help guys you really got me through this BS.. Ill let you know how the carb tuning goes in the next few days. I have to finish a few illustrations before i can go back out there, clients are lining up lol.

I got my website up and running recently what do you guys think? www.chriswilhelmart.com

Thanks for all your help guys you really got me through this BS.. Ill let you know how the carb tuning goes in the next few days. I have to finish a few illustrations before i can go back out there, clients are lining up lol.

I got my website up and running recently what do you guys think? www.chriswilhelmart.com

#30

And first gen,

I JUST rebuilt the carb with new parts and i know its not the bowl sticking because it goes and goes and goes when i kink of the gas line. new filters, new fuel pump, the whole 9. new fuel too. and i cleaned the tank awhile ago. I will DEFINATELY see what the compression is next thanks for that tip, and ill let you know. meanwhile ill still be messing with that carb i think i need to lean it out more but then again when i do that it doesnt want to idle.. lol IRONIC!

#31

oook so i finally had a chance to go out and compare pressure tests in the cylinders. first without oil being applied to the pistons via the spark plug holes the readers were (from 1 to 4) 70-75-90-110 or withing those areas(unfortunately i didnt write them down but its within 5 or so of those readings)..

when i re tested everything after putting a tablespoon of oil in the cylinders (to check the rings) i got about 10-20 psi on the first 3 cylinders.. number 4 didnt change it stayed at 110. none of the cylinders would get more than 110 pressure. i have the valves currently set (while hot) at .008 and .012 even though my cam calls for .007 and .009 could that make a huge difference? i know i keep asking the same question but im at a loss i dont think the rings are THAT bad do you? if oil gives a boost of about average 15 psi i would think theres enough margin of error to keep the thing atleast RUNNING. im thinking its either the valves, or the bottom end still. oh and the carb is set at lean best(not tuned but RUNNING while on the gas a little bit. its back to not idling or backfiring really bad over and over if i give it more than 2000rpm of gas.)

HELP!!

when i re tested everything after putting a tablespoon of oil in the cylinders (to check the rings) i got about 10-20 psi on the first 3 cylinders.. number 4 didnt change it stayed at 110. none of the cylinders would get more than 110 pressure. i have the valves currently set (while hot) at .008 and .012 even though my cam calls for .007 and .009 could that make a huge difference? i know i keep asking the same question but im at a loss i dont think the rings are THAT bad do you? if oil gives a boost of about average 15 psi i would think theres enough margin of error to keep the thing atleast RUNNING. im thinking its either the valves, or the bottom end still. oh and the carb is set at lean best(not tuned but RUNNING while on the gas a little bit. its back to not idling or backfiring really bad over and over if i give it more than 2000rpm of gas.)

HELP!!

#32

Hey Dude! At this point, were the vehicle mine, I would have to get another compression gauge just to make sure those numbers are valid. I hate to say this, but it's sounding like you bent your valves or burnt them. I'm more inclined to believe that some where your valves came in to contact with the pistions and bent slightly. Just enough so that they don't seat well. This can happen turning it over by hand. I've seen lot's of burnt valves, but I have never seen more than 2 in one engine and your problem is across all four cylinders. When it is running, do you feel air puffing up through the carb?

oook so i finally had a chance to go out and compare pressure tests in the cylinders. first without oil being applied to the pistons via the spark plug holes the readers were (from 1 to 4) 70-75-90-110 or withing those areas(unfortunately i didnt write them down but its within 5 or so of those readings)..

when i re tested everything after putting a tablespoon of oil in the cylinders (to check the rings) i got about 10-20 psi on the first 3 cylinders.. number 4 didnt change it stayed at 110. none of the cylinders would get more than 110 pressure. i have the valves currently set (while hot) at .008 and .012 even though my cam calls for .007 and .009 could that make a huge difference? i know i keep asking the same question but im at a loss i dont think the rings are THAT bad do you? if oil gives a boost of about average 15 psi i would think theres enough margin of error to keep the thing atleast RUNNING. im thinking its either the valves, or the bottom end still. oh and the carb is set at lean best(not tuned but RUNNING while on the gas a little bit. its back to not idling or backfiring really bad over and over if i give it more than 2000rpm of gas.)

HELP!!

when i re tested everything after putting a tablespoon of oil in the cylinders (to check the rings) i got about 10-20 psi on the first 3 cylinders.. number 4 didnt change it stayed at 110. none of the cylinders would get more than 110 pressure. i have the valves currently set (while hot) at .008 and .012 even though my cam calls for .007 and .009 could that make a huge difference? i know i keep asking the same question but im at a loss i dont think the rings are THAT bad do you? if oil gives a boost of about average 15 psi i would think theres enough margin of error to keep the thing atleast RUNNING. im thinking its either the valves, or the bottom end still. oh and the carb is set at lean best(not tuned but RUNNING while on the gas a little bit. its back to not idling or backfiring really bad over and over if i give it more than 2000rpm of gas.)

HELP!!

#33

stick a peice of paper or a playing card over the ehaust while running,if it sucks in....valves are toast.

exhaust should only blow air out.

this only works if exhaust is sealed...no major leaks.

exhaust should only blow air out.

this only works if exhaust is sealed...no major leaks.

#34

thanks for the tips guys, i just got back in from doing the intake and exhaust test. the intake sucks in HARD and doesnt push out at all so its my understanding that that is a good thing. the tailpipe ONLY pushes out, and yes theres a good seal on there so i think its time to rule out valves,(but maybe not i dont know).

What i REALLY want to know is by inproving the compression by about 20 psi or so on average when i put oil in the cylinders, is that enough to make me have the problems im having now(low compression) or would new or semi new rings allow for the same improvement. basically in simple terms... are my rings going to be ok? lol

and geez i still dont know what to try next. everything SEEMS to be in working order but its just not. heres another question. its a bit of a newb question sure but i was never really told.. when im adjusting the valves should the tool im using to measure with go in smoothly and without effort between the lobes of the cam and the rockers or should i have to kind of push it in almost not letting the tool in at all? what i have been doing so far is right in the middle. i make it so i can feel it sliding in but not enough to where i have to actually force anything in.. at all. I would almost say im on the loose side but bearing in mind that im trying to be right in the middle.

Thanks!

What i REALLY want to know is by inproving the compression by about 20 psi or so on average when i put oil in the cylinders, is that enough to make me have the problems im having now(low compression) or would new or semi new rings allow for the same improvement. basically in simple terms... are my rings going to be ok? lol

and geez i still dont know what to try next. everything SEEMS to be in working order but its just not. heres another question. its a bit of a newb question sure but i was never really told.. when im adjusting the valves should the tool im using to measure with go in smoothly and without effort between the lobes of the cam and the rockers or should i have to kind of push it in almost not letting the tool in at all? what i have been doing so far is right in the middle. i make it so i can feel it sliding in but not enough to where i have to actually force anything in.. at all. I would almost say im on the loose side but bearing in mind that im trying to be right in the middle.

Thanks!

#35

thanks for the tips guys, i just got back in from doing the intake and exhaust test. the intake sucks in HARD and doesnt push out at all so its my understanding that that is a good thing. the tailpipe ONLY pushes out, and yes theres a good seal on there so i think its time to rule out valves,(but maybe not i dont know).

What i REALLY want to know is by inproving the compression by about 20 psi or so on average when i put oil in the cylinders, is that enough to make me have the problems im having now(low compression) or would new or semi new rings allow for the same improvement. basically in simple terms... are my rings going to be ok? lol

and geez i still dont know what to try next. everything SEEMS to be in working order but its just not. heres another question. its a bit of a newb question sure but i was never really told.. when im adjusting the valves should the tool im using to measure with go in smoothly and without effort between the lobes of the cam and the rockers or should i have to kind of push it in almost not letting the tool in at all? what i have been doing so far is right in the middle. i make it so i can feel it sliding in but not enough to where i have to actually force anything in.. at all. I would almost say im on the loose side but bearing in mind that im trying to be right in the middle.

Your welcome!

#37

Damn.. ok ive started the tear down. im down to the pistons but there was enough oil on the ground to grease an elephant so i pressure washed the driveway before attempting to remove the 100 bolts for the oil pan to get to the pistons underneath.

1stgenboy, no the valves all look really good from top side and bottom side. im going to upload some pics for you guys to examine i have no idea what im looking for. turns out the pistons on ROCK brand and are .050 so im assuming this is max bore? now what is a ridge reamer and how do i use it? what should i be looking for here this is all new to me ive never taken pistons out before.

and how would i check to see if my valves are still seating well? they look alright and are newish but i dont want to go through all of this new rings and stuff just to find that it was my valves all along. and that being said, wheres the best DEAL (im totally broke right now and want to do this on the cheap. but obviously not too cheap i dont want to be here again for awhile) for rings, and wrist bearings and all that crap?

man your being a life saver for me THANK YOU THANK YOU THANK YOU! if you ever come close to salem or portland ill have my wife bake you some cookies!

ill have those pics up soon.

1stgenboy, no the valves all look really good from top side and bottom side. im going to upload some pics for you guys to examine i have no idea what im looking for. turns out the pistons on ROCK brand and are .050 so im assuming this is max bore? now what is a ridge reamer and how do i use it? what should i be looking for here this is all new to me ive never taken pistons out before.

and how would i check to see if my valves are still seating well? they look alright and are newish but i dont want to go through all of this new rings and stuff just to find that it was my valves all along. and that being said, wheres the best DEAL (im totally broke right now and want to do this on the cheap. but obviously not too cheap i dont want to be here again for awhile) for rings, and wrist bearings and all that crap?

man your being a life saver for me THANK YOU THANK YOU THANK YOU! if you ever come close to salem or portland ill have my wife bake you some cookies!

ill have those pics up soon.

#39

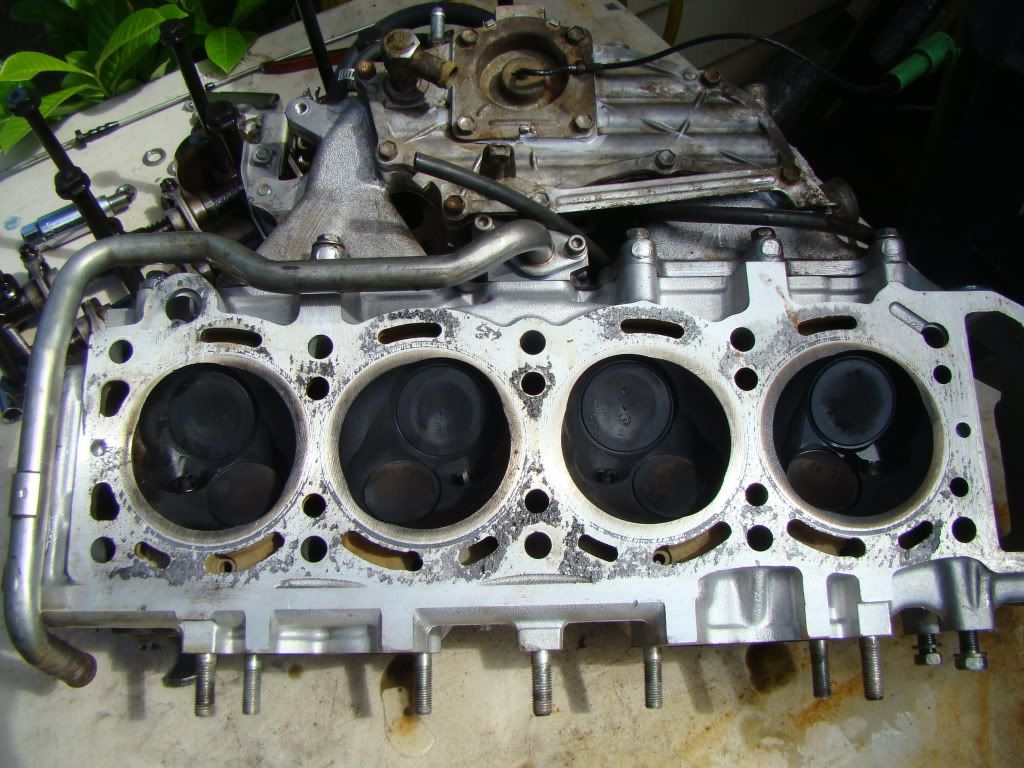

ok so its all taken apart. i only took the #1 piston out just to examine and to verify what i have in my block. so here are a few shots of what ive found so far. nothing out of the ordinary i dont think but again im completely new to the lower end as far as hands on experience goes. i didnt need a ridge reamer to get the piston out it came RIGHT out.

the bearings still look new with a TINY bit of break in wear so im gonna keep them i dont really have an extra 20 bucks at this point for new ones.

here is the #1 piston let me know if you think its ok to put back in, no damage as far as i can see but i dont know what to look for other than scoring on the skirt or the cylinder wall. the walls look to be not PERFECT but not scratched up too bad either. what do you think?

here is a pic of the valves.

[IMG] [/IMG]

[/IMG]

and here is the bore. it might be hard to see but let me know if you think i need any work done. if i need machine work im gonna have to put this aside for the time being so im HOPING you will say it looks fine, or give me a way to check thats free or cheap.

and finally, here is the head from underneath. the seats of the valves SEEM ok but is there really a visual way to check? let me know your thoughts..

ok let me know what you think and if i need any more pics just let me know. the piston says its 050 so that is max bore right? meaning if i need another bore ill have to get another bottom end? yikes... i thought it was 030. anyway rings are ordered and on their way.

Thanks!

the bearings still look new with a TINY bit of break in wear so im gonna keep them i dont really have an extra 20 bucks at this point for new ones.

here is the #1 piston let me know if you think its ok to put back in, no damage as far as i can see but i dont know what to look for other than scoring on the skirt or the cylinder wall. the walls look to be not PERFECT but not scratched up too bad either. what do you think?

here is a pic of the valves.

[IMG]

[/IMG]

[/IMG]and here is the bore. it might be hard to see but let me know if you think i need any work done. if i need machine work im gonna have to put this aside for the time being so im HOPING you will say it looks fine, or give me a way to check thats free or cheap.

and finally, here is the head from underneath. the seats of the valves SEEM ok but is there really a visual way to check? let me know your thoughts..

ok let me know what you think and if i need any more pics just let me know. the piston says its 050 so that is max bore right? meaning if i need another bore ill have to get another bottom end? yikes... i thought it was 030. anyway rings are ordered and on their way.

Thanks!

#40

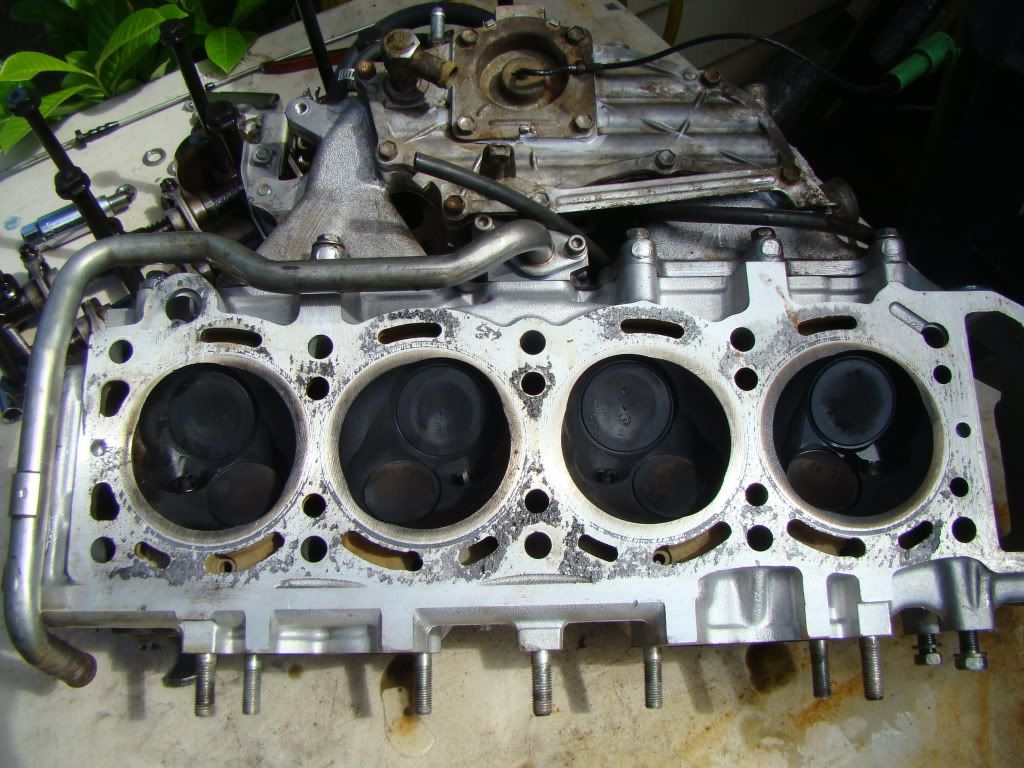

ok so the first 3 pistons didnt give me any grief about coming out but when i got to that 4th piston man was it a pain in my ass. (remember this is the one that stayed at 110 psi even after the oil was added to the cylinder) Well i found out why it was a pain to get out. here a few pics of the intake side of the skirt. its pretty scratched up im not sure if its too bad to reuse or what? can i sand it down and make it alright? the bore seems fine the scratches arent nearly as bad and i cant feel them at all with my finger. also theres little to no ridge to ream away so thats a plus.

what could have happened to this piston? and why did it get messed up when the others are perfect?

the closest piston is #1 and the farthest and damaged one is #4

thanks!

what could have happened to this piston? and why did it get messed up when the others are perfect?

the closest piston is #1 and the farthest and damaged one is #4

thanks!