Last edit by: IB Advertising

See related guides and technical advice from our community experts:

Browse all: Interior Guides

- Toyota 4Runner 1984-1995 Why is Interior Rattling

Guide to diagnose trouble and recommended solutions

Browse all: Interior Guides

Sound-Proofing/Deadening & Interior Work

#1

Sound-Proofing/Deadening & Interior Work

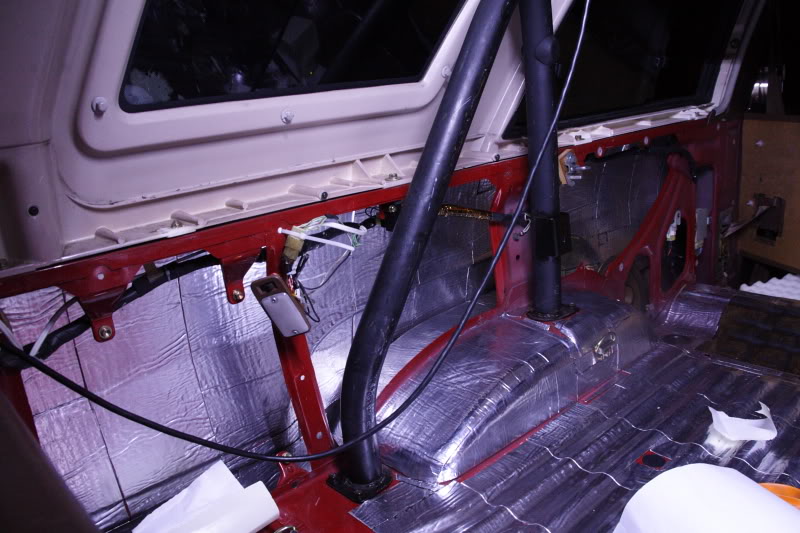

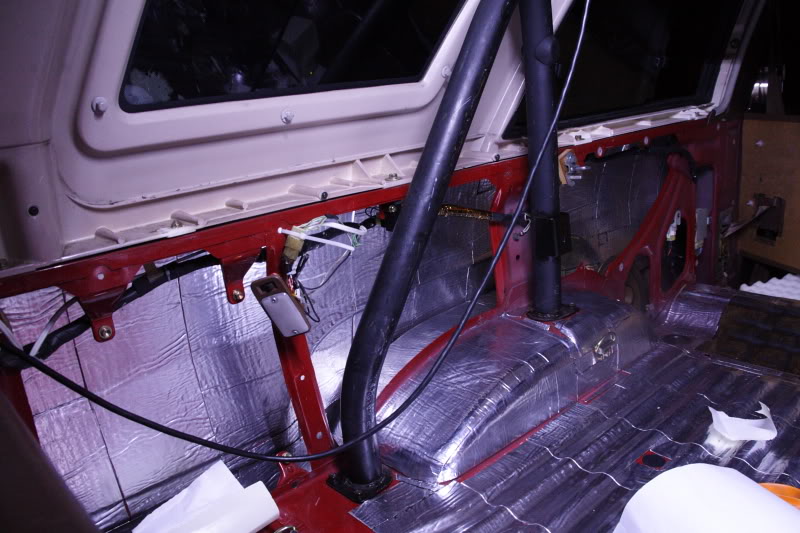

There is not a single bit of sound-proofing on the side panel and minimal on the floor (although there's tar on floor) nor insulation to keep remaining vibration from coming through into the cabin. Many people, including me, sweat the details/materials of sound dampening materials. However, the brand-name ones are still too expensive for my budget. People also talk about toxicity of materials, so I asked B-Quiet for MSDS and MSDS says "bitumen" - same as asphalt-based Peel and Seal. I looked at Peel & Seal MSDS and see nothing about toxic fumes. Only possible skin irritation from adhesive. Heck, I sleep on rocks & dirt and wash my face with laundry soap! LOL! What's a little skin irritation, besides I don't want to spend more than 5% of what I paid for truck on sound-proofing. Also mixed reviews about asphalt/tar smell. So Peel & Seal it is.

Already peeled rear deck carpet and ran it through a wash in front-loading washer. No detailing service can beat that! About half-way done with P&S application. Completely covered inner side panels really highlights space inside these walls-Very promising for stealth speaker enclosure project!

Next free weekend:

I'm in the middle of my sound-dampening/proofing project and have peeled off carpet and padding. Now, I'm left with some padding fiber stuck on stock tar sound-deadening on front deck.

Updates:

Steel Brush wheel on power drill worked well to remove fuzz fast.

For thermal insulation from engine and transmission hump heat, I used Thermo Shield thermal insulation padding from Pep Boys. Thanks, Chef, for the lead! It has fibrous padding and aluminum foil on one side.

4' x 6' roll is enough to cover:

On left side, firewall, to rear passenger floor, and up the vertical wall juts short of where passenger seat bottom hinges mount. This will insulate from engine and exhaust pipe heat.

On right side, firewall to frame cross - member under front passenger's seat. The floor on back, right-side does not need thermal insulation

Transmission hump, from firewall under dash all the way to where floor rises to back seat bottoms.

For Rear Deck: Used Best Step closed-cell anti-fatigue mat from Sears. Trimmed to fit.

Will post pics when I get the chance

Already peeled rear deck carpet and ran it through a wash in front-loading washer. No detailing service can beat that! About half-way done with P&S application. Completely covered inner side panels really highlights space inside these walls-Very promising for stealth speaker enclosure project!

Next free weekend:

- Remove seats,

- Peel off carpet and wash

- Apply more peel and seal and possibly thicker under-carpet insulation/padding

- Re-apply carpet,

- Use rubberized floor mats for better sound-dampening/proofing.

I'm in the middle of my sound-dampening/proofing project and have peeled off carpet and padding. Now, I'm left with some padding fiber stuck on stock tar sound-deadening on front deck.

Updates:

Steel Brush wheel on power drill worked well to remove fuzz fast.

For thermal insulation from engine and transmission hump heat, I used Thermo Shield thermal insulation padding from Pep Boys. Thanks, Chef, for the lead! It has fibrous padding and aluminum foil on one side.

4' x 6' roll is enough to cover:

On left side, firewall, to rear passenger floor, and up the vertical wall juts short of where passenger seat bottom hinges mount. This will insulate from engine and exhaust pipe heat.

On right side, firewall to frame cross - member under front passenger's seat. The floor on back, right-side does not need thermal insulation

Transmission hump, from firewall under dash all the way to where floor rises to back seat bottoms.

For Rear Deck: Used Best Step closed-cell anti-fatigue mat from Sears. Trimmed to fit.

Will post pics when I get the chance

Last edited by RAD4Runner; 11-04-2012 at 05:40 PM.

#4

#5

I don't doubt dry ice works, but also a torch works great too. Hopefully the OP will try both ways and report back which one worked best for him...

#6

This is a forum correct? Usually people post up ways they were able to get the job done and it's up to the OP to decide what is best for them. Kind of like the old saying of...there is more than one way to skin a cat.

I don't doubt dry ice works, but also a torch works great too. Hopefully the OP will try both ways and report back which one worked best for him...

I don't doubt dry ice works, but also a torch works great too. Hopefully the OP will try both ways and report back which one worked best for him...

you know, so I could get your opinion on the two methods as well. Or to see if you knew of some reason not to use dry ice.

it was simply a question directed at you, I wasn't trying to be snippy.

Trending Topics

#8

Clarification

Hi guys,

Sorry, I should have asked more clearly. Tar sound dampener is in good shape, so I don't need to remove it. I would like to:

Tnx!

Sorry, I should have asked more clearly. Tar sound dampener is in good shape, so I don't need to remove it. I would like to:

- Supplement it with a layer of Peel and seal, so I only need to remove the left-over fiber of padding so P&S will stick to cleaner surface. .

- Apply P&S on drive train bump, and firewall. Currently no sound-deadener on some sections.

- Add sound insulation in form of closed-cell foam so would like to know if you've gotten good results with closed-cell foam, instead of the fibrous padding.

Tnx!

Last edited by RAD4Runner; 10-01-2012 at 02:53 PM.

#9

Hi guys,

Sorry, I should have asked more clearly. Tar sound dampener is in good shape, so I don't need to remove it. I would like to:

Tnx!

Sorry, I should have asked more clearly. Tar sound dampener is in good shape, so I don't need to remove it. I would like to:

- Supplement it with a layer of Peel and seal, so I only need to remove the left-over fiber of padding so P&S will stick to cleaner surface. .

- Apply P&S on drive train bump, and firewall. Currently no sound-deadener on some sections.

- Add sound insulation in form of closed-cell foam so would like to know if you've gotten good results with closed-cell foam, instead of the fibrous padding.

Tnx!

why use an asphalt based mat? out of curiosity?

butyl rubber based mat has come down in price in the recent years so much that its incredibly hard to justify using asphalt based products when its been proven that you need 2-3 times as much to get the same effect?

I would honestly use something like Rammat instead and just use less of it, thats just my experience though.

Also, for any deadening mat to function properly it needs to be bonded to the surface your trying to deaden (IE: the metal floor pan not the tar) so you would definitely get better results by removing all of it first.

Anyways, you dont have to do all that... I'm just telling you while you've got it all torn out you would get far better results by doing the full job.

If you just wanted to remove the fuzz, Acetone/Mineral Spirits should do the trick.

#10

why use an asphalt based mat? out of curiosity?

butyl rubber based mat has come down in price in the recent years so much that its incredibly hard to justify using asphalt ...I would honestly use something like Rammat instead and just use less of it, thats just my experience though....

If you just wanted to remove the fuzz, Acetone/Mineral Spirits should do the trick.

butyl rubber based mat has come down in price in the recent years so much that its incredibly hard to justify using asphalt ...I would honestly use something like Rammat instead and just use less of it, thats just my experience though....

If you just wanted to remove the fuzz, Acetone/Mineral Spirits should do the trick.

It's a sub-$3K truck

so I don't wanna put 10% of the price on sound-proofing. PLUS

so I don't wanna put 10% of the price on sound-proofing. PLUS I considered B-Quiet & RAMMAT but:

- When I looked at B-quiet MSDS, it also said, Bitumen- which is exactly same as P&S

- When I asked RAMMAT for MSDS, I did not get any response.

Last edited by RAD4Runner; 10-01-2012 at 08:51 PM.

#12

in that case acetone should work just fine for you

I wish I still had pictures of my previous deadening jobs, but alas... I suck at keeping pictures

whenever I get around to doing this truck ill put up pictures of everything: floor, roof, rear wall, firewall, inner and outer door skin, the whole 9 yards in 1-2 layers of second skin

I wish I still had pictures of my previous deadening jobs, but alas... I suck at keeping pictures

whenever I get around to doing this truck ill put up pictures of everything: floor, roof, rear wall, firewall, inner and outer door skin, the whole 9 yards in 1-2 layers of second skin

#13

wvcoalminer, yes; that's why I'm considering closed-cell foam, instead because it will add waterproofing.

dcole, I also want to do my roof and firewall. Because of potential adhesion/melting problem with cheap P&S on roof, I'm considering the better-sticking products.

For engine side of firewall, I have B-Quiet's Highliner in mind.

Folks, Please share your experience with sound-deadening on roof & firewall. What have you used that did not peel off? I will also supplement that with pad secured to "ceiling" with straps= additional sound-proofing from wind noise and will double as sleeping pad when camped.

Unfortunately, there's too much parts in tailgate to prevent convenient application of dampening.

#14

Holy Crikey, this is a good thread. I was going to tell my horror story about removing that stuff to bed line the inside of a cab....

And yes, that tar is tough to remove lol. I tried aircraft paint remover, no joke. Did an ok job but it was a LOT of elbow grease.

I like this sound deadening gig you speak of. The 2 tacos I had were pretty silent inside for the most part as compared the the plethora of 81-95 Toy 4x4's I have owned. I do appreciate a strong and well installed stereo system as well since back when I was a little punk stereo and tint were my larger concerns, and I can see where sound deadening would be monumental in that quest.

And yes, that tar is tough to remove lol. I tried aircraft paint remover, no joke. Did an ok job but it was a LOT of elbow grease.

I like this sound deadening gig you speak of. The 2 tacos I had were pretty silent inside for the most part as compared the the plethora of 81-95 Toy 4x4's I have owned. I do appreciate a strong and well installed stereo system as well since back when I was a little punk stereo and tint were my larger concerns, and I can see where sound deadening would be monumental in that quest.

#15

The above "after" pics accentuate how much space there is to potentially install a "Stealth" speaker and/or sub-woofer system. I'm brainstorming how to do it...

Use good quality 2-way speaker and possibly add a powered sub later.

Also build-in a sub woofer enclosure into that space.

Build-in a real enclosure? Advantages are:

Significant improvement over simply mounting even good speakers on flimsy stock panels.

Real enclosure is additional barrier between passengers and vibration from side body panels. Add to that the dampening I could add between back of enclosure and body panel.

Possible construction methods are:

Make and pre-assemble enclosure then install in space if it will fit. OR

Design so walls of enclosure will wiggle into opening, then assemble after they are inserted into space. If not,

Fabricate fiber-glass enclosure to fit space. Could be messy, and I have no experience doing that.

Also considering replacing rattly plastic rear side panel with plywood with sound absorbing foam backing.

Use good quality 2-way speaker and possibly add a powered sub later.

Also build-in a sub woofer enclosure into that space.

Build-in a real enclosure? Advantages are:

Significant improvement over simply mounting even good speakers on flimsy stock panels.

Real enclosure is additional barrier between passengers and vibration from side body panels. Add to that the dampening I could add between back of enclosure and body panel.

Possible construction methods are:

Make and pre-assemble enclosure then install in space if it will fit. OR

Design so walls of enclosure will wiggle into opening, then assemble after they are inserted into space. If not,

Fabricate fiber-glass enclosure to fit space. Could be messy, and I have no experience doing that.

Also considering replacing rattly plastic rear side panel with plywood with sound absorbing foam backing.

Last edited by RAD4Runner; 11-04-2012 at 05:43 PM.

#17

That's going to work nice. I did some of my own rear panels in an FJ60 some years ago. I went as far as to build particle board enclosures in the rear panels that had -close- to the cubic inches needed per speaker, and made my own panels out of 1/4" fiber board that was rhino lined on both sides. It turned out well, looked good, sounded good and was tough and easy to install. I didn't go as far as to make the mounting pegs (christmas trees?) work to mount the panels, I used countersunk sheet metal screws with washers for that "robust" ghetto look. It was only an $800 truck so I didn't want to go too far knowing I wouldn't keep it forever but it served it's purpose.

This looks like a fun project but don't forget the rear suspension! You'll need it to hold up all the wiring and speakers

Just like how I have to lift the rear of my truck because it needs new shocks.... some things just have to be done

This looks like a fun project but don't forget the rear suspension! You'll need it to hold up all the wiring and speakers

Just like how I have to lift the rear of my truck because it needs new shocks.... some things just have to be done

#18

That's going to work nice. I did some of my own rear panels in an FJ60 some years ago. I went as far as to build particle board enclosures in the rear panels that had -close- to the cubic inches needed per speaker...I used countersunk sheet metal screws with washers for that "robust" ghetto look. This looks like a fun project but don't forget the rear suspension! You'll need it to hold up all the wiring and speakers

Just like how I have to lift the rear of my truck because it needs new shocks.... some things just have to be done

Just like how I have to lift the rear of my truck because it needs new shocks.... some things just have to be done

Luvmeye22re,

Yes, wood (MDF) makes better acoustic than the flimsy plastic panels. I would also like to replace the hidden fasteners with screws as I go (or as I break them), 'cause I want that / rugged/ tear-down functionality.

Last edited by RAD4Runner; 10-12-2012 at 06:45 AM.

#20

Registered User

iTrader: (4)

Joined: May 2010

Posts: 720

Likes: 15

From: People's Republic of California

That kind of stuff really does make a difference (I used fatmat). I would recommend putting an extra layer on the firewall, on the transmission hump and under the driver side (specially if you have a header that goes right underneath). You should do your front doors like you did the rear bed walls, that made a difference in mine. It's difficult to get to, but just use many small strips instead of one big one.

I have a pickup and you have a 4runner so you probably have different areas that may need a little more attention. For example, pickups get wind noise from between the the rear cab wall and the bed, the 4runner looks like it gets some extra noise from the whole bed area and where the muffler is underneath.

Just remember the stuff can get heavy.

I have a pickup and you have a 4runner so you probably have different areas that may need a little more attention. For example, pickups get wind noise from between the the rear cab wall and the bed, the 4runner looks like it gets some extra noise from the whole bed area and where the muffler is underneath.

Just remember the stuff can get heavy.